Max torque is also important and the rpm at max voltage (12-14S) should not be too high so you can use an efficient prop with a diameter between 130 and 170mm. Therefore most poeple chose 120KV for a direct drive (unless you want to add a gear).

Why is 7.25x5 a no go? I am new and couldn’t find any reasons yet

It’s ineffecient, unbalanced (this damages the motor). You can 3d print better props…

Hi Pablo, Could you please share the file for a six inch duct with me again. The link does not work right now. My email is gummigeldprofi@gmail.com.

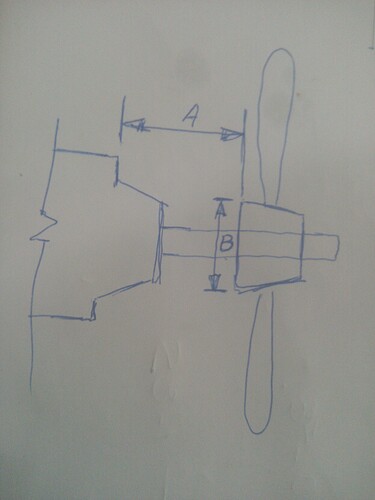

Send me this information and drawing of your motor to see position of screws.

Do you have the fairing STL for a 65162.

Do you have an STL for the Maytec motor fairing. Im looking for a fairing that will extend the distance from the motor to the prop. See below.

Try it, I reconstructed it last week because my new 7”FR Propeller have little bit other dimensions.

Now I had time to print and mount it.

Seems to me the Hub is fitting

Very nice looking! Will be interesting, if possible to measure, to see if the cone behind the propeller has positive, negative or no effect on efficiency, nothing is certain in this case.