Doesnt gearbox/reduction also gets momentum up and with that in mind, pulls amps down? Just like a gearbox on a regular car? Yes it gives acceleration but why not benefit with higher rpm and higher reduction to get better output momentum? I dont see speed and acceleration the problem, only momentum…

I would like to show but I am afraid of damaging my copyright. This forum is also attended by industrial spies who are looking for different technical solutions for their projects. But I’m willing to test various commercial and prototype propellers, I can advise on how to increase their efficiency and the like.

I do not want to deal with the disadvantages of gearboxes in this topic, I consider it unnecessary for e-foil. When you put the first gear in your car, it’s only suitable for starting at zero speed. And the e-foil does not need the first gear because at the start time, the engine has 50% of the maximum RPM. Therefore, racing boats even use a gearbox to increase the shaft speed from the engine (transfer to speed).

I agree with you , 40mm is too small for a +30km/h application , but i beleive a 36mm motor with gearbox can do the job for 20km/h … It is always nice to pull less amp with a better propeller …

I am always full throttle , stable rpm ± 300rpm , for me acceleration = 0 (?)

It seems pretty hypocritical that you want to test others designs that they may go commercial with if they are good enough, but are not willing to share your designs (or are you planning on just taking their ideas?). If your designs were already in real world applications, then various “industrial spies” would already have seen them and could copy them regardless. So what exactly are you planning to do with your copyrighted propellers?

Usually, it works just the other way. For us, more than for anybody else, using small and super-high rpm brushless that will fall out of any feasible propeller design, for cavitation least but not last. I’m an engineer in marine business industry, that produces any size of thrusters, hence propeller. Not good for our purposes here, because bi-directional and high steady thrust oriented. There should be a good balance between rpm, prop diameter and efficiency. We have the “complication” of speed also…with efoil, but 10k rpm are not the better starting point, that’s where a gearbox comes handy. More torque less rpm bigger diameter more efficient prop

I do not plan to have much higher RPM with the smaller motor. My current design uses 100Kv with 47V with 6384PG. Assume 150Kv with 32V, almost same RPM will output. As i drive a large windsurfboard without foil, my average power demand is much higher, than with foil. The last ride was with 15km/h at 1500W. As i wrote, 130-150mm ducted prop is the goal. The prop is a cut down commercial aluminium prop which costs 25$. Yamaha 7 1/4 x 6 or 7 or 8, even 5" is available.

To build such things i use a cheap lathe from rotwerk, costs around 350€, can be purchased anywhere. Without a lathe, its impossible.

Wih 50mm instead of 63mm we save 37% of frontal area and thereby induced drag. The prop gets more area at the same time.

Forget copyrighting propellers, its the same as with electric machines, all the important patents are written. I try to publish everything here, so it cannot be patented any more. Patenting or copyrighting such things is a loosing game, you only spend money for lawyers and fees, and in the next moment someone bypasses your idea. Its not worth it in most cases, you loose your time with nonsense. Get a nice job instead and enjoy working in a large company with a competent team on things that matter. My 50 cents.

Racing boats also dont have space, storage and power limitations like an e foil. And here we just use reducer practically aka singlegearbox. E foil dont need multi gear box since momentum is quite bigger than in regular IC car engine but if it lacks momentum, math is simple on how to get that extra needed Newtons with some mechanical help at the same power levels. I know u dont want to focus on disadvantages of a gearbox, but people focused on advantages and its working quite well since a lot people are foiling. A lot of them would agree gearbox is “useless” part for an efoil regarding everything from price to simplicity but people are foiling. And we established long ago that we need that “perfect” motor. I believe that good motor/prop combo without gearbox exists but what would u say to every efoiler here who uses gearbox and has a very well working system?

Not needed.

This thread is about direct drive with outrunners, optionally with direct cooling.

The advantage is price, simplicity and durability. No sealings, no tube, no gears, no couplers, no cry. Just a phase current controller, like VESC. Much smarter. It will roll up the market.

My apologies, saw gearboxes “rendered useless” but didnt see the name of the thread.

Let’s go back on thread. As " geared efoiler" with already a failure and money gone for two gearbox, I’d love the idea of such simplicity. My wet dreams are one day over jet (damn sexy), the other on wet outrunner, I flirted also with belt driven reduction but performances of a well suzed geared propeller are still the real fatal attraction! Still, I can’t stop here, gearboxes fails, cist lot of money and are rare to find. Jet, direct or DIY planetary?

So lets talk about the problems to solve for direct drive direct cooling.

I managed a lot of them, but there are some unsolved.

One is about changing bearings and assembling/disassembling the rotor from stator.

To avoid loosing the rotor/prop you need a circlip which is almost impossible to mount whithout dissoldering the motor phase leads.

If we want a breaktrough we need to solve this problem.

One possible solution is a clamp ring instead of a circlip.

Another topic is the adaption from motor phase leads to leads into the mast. The phase leads can be covered with epoxy or other resin to make it waterproof and stable. But the adaption from the stranded motor leads to flexible wires in the mast is not solved in a good way. It needs to be watertight, even if the voltage is not deadly. An interface in the backplate of the outrunner would be good, giving some mechanical stability. This could be done by motor manufacturer, but how?

Not sure to get the circlip issue… Do you have a photo to show that?

For the circlip, i can take mine off without disconnecting the wires… i’m using 80-100 with a short custom made titanium shaft (ok, just a bar bought out of ebay with minor modifications without lathe, only using sand paper, dremel and drill press),it’s short enough to not extend pass the stator backplate.

i’m thinking about drilling and taping the end of the shaft to replace the circlip by a washer and a screw…

for the connection: connectors would be great… for now i’m using adhesive lined shrink tubing over bullet connectors…

but after i’m back on the water, connectors are the next step … may be grease filled to help…

direct cooled out runner might need more assembly disassembly than other solution to clean them up regularly…

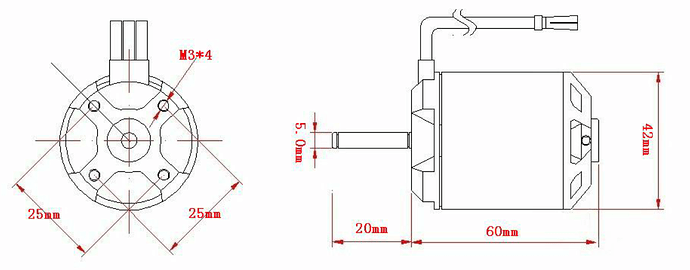

Original drawing as an example:

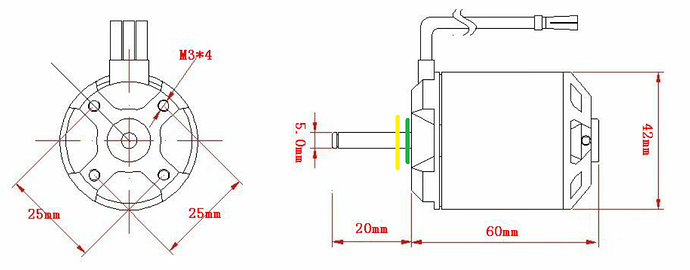

Circlip with cut shaft (yellow) and circlip (green):

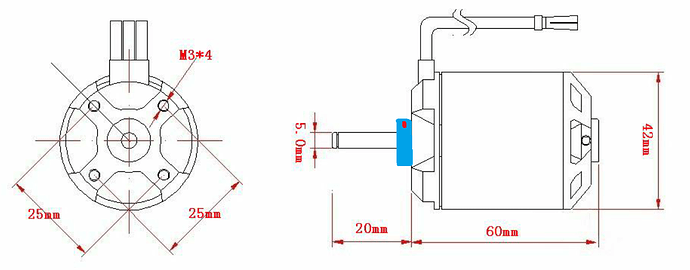

Clamp ring (blue):

The problem is, you cannot reach the circlip with the pliers while the motor is mounted. With a clamp ring you could reach the red colored allen key from the side without disassembling the motor from its mount. By this you can draw off the bell, the rotor from the stator to maintain or change the bearings (if its needed).

The reason electric motors generally do not need gearboxes is not because it has 50% of maximum RPM on start up, but because it has 100% of its torque from 0 RPM.

Sorry to ask , but in your motor , we should put the propeller on the shaft or on the back ?

I really want to try

For me i think the motor , espacially in the outrunner setup, is the" conspumtion part" , if we need to change motor once a year and battery once every 2 years , it is not a big deal …

For the propeller , commercial , modded tried , best resultat i got was from re shape the all propeller smaller , not just cut it in diameter ( top right)

@PowerGlider You could do away with the circlip depending on motor orientation, if it is a pusher, the c-clip is not needed. This way after use the rotor could be pulled off by hand and bearings maintained very easily.The motor mount could go sit over the lip of the bearing so it doesn’t slide out.

With the 50mm out runner would the motor have enough mechanical advantage for direct drive? we can only find out by testing!

Mat, I have been out of town. There are 3 types of bearings in my out runner. 1 big, 2 medium, 2 small.

I did not replace the small ones. they seem fine. This is where I got them.

I believe my E-foil grinding noise “only under load” was caused by a bad connection on one of my phase wires. I think the grinding noise was caused by the motor de-syncing. The problem kind of just went away when I was fussing around with the phase wires. So I cleaned things up. No more problem. I took it for a ride. Seemed to work good.