Our ideas for the future will allow some turnover of water in the motor.

This motor looked interesting from the electric skateboard forum.

I did one more test on the Leopard 8072 160kV motor this evening. I removed the tail cone and water seal and then ran the motor dry to see how much power the seal was draining.

Motor only, no seal, no prop, in air: 44.5V 4.3A 191W

I’m a little surprised the power used was this high; the motor turns easily with my fingers.

Can you estimate the RPM at full throttle? Is it higher than it used to be before all these underwater testing?

very impressive. thanks for posting. I believe you will need to be closer to 60 lbs of thrust initially for lift off, but you probably already know that.

all the best

We are definitely taking off with less than 60lb of thrust. The 35lb with the dry motor is the setup from our video 5 and it was our most successful test to date. Now, with a smaller board it will take more thrust and we will be using a smaller and much lighter board when we resume testing. We also found that you want to let the board get up on speed and slowly climb on to the wing to maintain stability. As you get faster the drag does tend to peak early as the wing starts to provide lift and reduce the drag from the board.

I wanted to do some drag tests but all of my friends boats and jet skis are put up for the winter now.

And another test. I ran this same motor submerged with no shroud for comparison.

1,100 watts, 33A with no propeller. The water was really churning.

This is unplausible to me. Can you measure the no load RPM in air? Already the current draw in air was way too high, looks as if the magnets got demagnetized, than the RPM becomes much higher and the efficiency can decrease dramatically.

You should limit the mass flow by some hydrodynamic optimization, otherwise it acts as a centrifugal pump with the large arms at the head. My setup has only small holes where the water is drained.

Also the source holes are small, so no big particles can get inside.

The “no load” power loss seems too high to me too. I’ll check rpm when I return home. The motor appears to run the same now as it did when I first received it.

c[quote=“PowerGlider, post:48, topic:362”]

You should limit the mass flow by some hydrodynamic optimization, otherwise it acts as a centrifugal pump with the large arms at the head. My setup has only small holes where the water is drained.

[/quote]

The testing FancyFoam and I did was to show the comparitive effect of different motor configurations:

- enclosed motor dry

- enclosed motor flooded

- motor with no enclosure

The relative results were as expected. We did expect that an unenclosed motor would have high power loss due to the water pumping action of the motor itself. …Now demonstrated clearly.

This test has no practical value, sorry for not telling how to design it before.

Dont know yet Magic Bruno is still waiting for it to arrive

This conflict does not make sense to me. We all have different approaches. It is good to read about your experience.

Brunos magic words, when will they be a reality.

Hi PowerGlider,

Im searching for simple methods of motor coating for waterproofing besides applying epoxy.

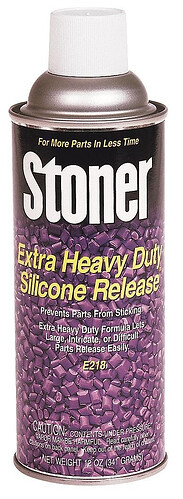

I will appreciate your opinion about motor waterproof with silicone spray coating, like this:

As per this forum below it shows very good results comparing to other simple methods

https://forum.openrov.com/t/seawater-vs-brushless-motors/35/4

What do you think to apply it with several layers and repeat it from time to time (lets say after each 3rd ride)

It depends.

There are different problems. The windings could consist of Copper wire with different coatings. The Iron core of a outrunner consists of thin iron plates which corrode fast but could be impregnated or at least passivated before caulking them together. It depends.

Why is it good to use some stable coating for the windings? When the water is between the winding packages it generates higher forces at high RPM than air. So if single wires can move, the isolation might break down. You get a connection to sea water or direct short between single wires, the performance will go down. So one issue is to improve the stability of winding package.

Iron core: The thin plated iron is corrosive, passivation does not help too much. It is done to reduce eddy currents and to build up a kind of insulation between the layers, it does not need to be perfect and caulking will open the passivation layer at every lamination. Sometimes the core is also baked afterwards to remove mechanical stresses. Anyhow, it is surely not seawaterresistant.

The problem i see with such sprays, that not every cavity can be reached by such process.

So somehow the air has to go and something else shall take place.

How can you achieve this? Frequent vacuum. It is not enough to apply it once, you need to apply it several times to expand the air in the cavities by lets say factor 2, some of the air will leave. Now you apply normal pressure again, the air will collaps, the fluid material will go in a bit. Next time you apply vacuum you have less air coming out. Repeat until you do not see any air coming out.

I am sure, such silicone release spray is a good barrier, but how can it reach these cavities? By capillary force only? I think it would dry on its way. Check it out.

I will write some more details in my thread about the details building vacuum chamber cheapiest way.

Have you tested it with a prop yet? I see a lot of people using gearbox, please let us know how yours does with direct drive.

hMrmoerbe,

Yes, the direct drive has been tested with a prop. “In the lake” testing is shown in the video below.

Lake testing started with the Leopard motor and a Solas propeller. I was hoping that an “off the shelf” motor and propeller would work well. The motor was way over-propped with the Solas propeller and we were limited to 24 volts in order to avoid excessive amps. Mike printed a pacificmeister designed prop that I fitted to the Leopard motor. This worked better but the motor was still over propped. We kept cutting the prop down little by little to try to get the lowest wattage for the required thrust.

After the lake tests were finished, we did some “quicky” testing in FancyFoam’s pool to see the effect of running the motor with a flooded compared to a dry enclosure (both with a prop installed) and then also the effect of no enclosure (no prop) enclosure.

I’ve now ordered a stronger, lower kV motor, the Alien C80100 50 kV. The plan is to do much pool tesintg to find a good propeller for this motor.

Thank you very much for your effort to explain your experience. Sounds like vacuum chamber is must… Will try to build it.

Congratulation as i see you , your rear legg must absolutely place on the mast if you want to go on the air .

Don’t forget to pop your rear legg it can help you