I know you’re not a rookie in the battery game, but that metal ruler is kind of scary!

I wouldn’t trust myself to not casually measure the height…

hehe thanks @alexnz - I remember when one day I thought cuting my positive and negative cables of my 12S lipo … in one go with the same plier. That spark was amazing and unexpected… and the plier was done!

hello team!

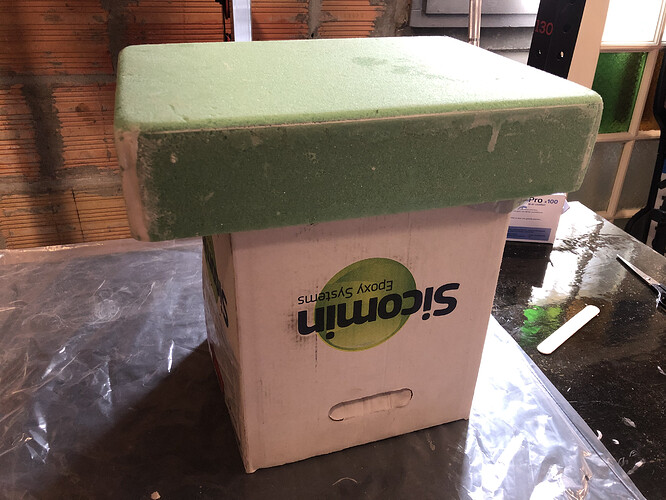

I’ve received today the order from SICOMIN (composites & Airex). The Airex sheet will be delivered tomorrow but I got the epoxy resin and some material and Carbon Fiber/Fiber Glass rolls.

I will then try to make the box out of Airex and composites and see how it goes.

Hi there,

I’ve received my Airex 5mm sheet today and I’ve started to create the box by cutting panels. I decided to double the size of the walls by epoxying two panels together which will give me 1cm thickness that will provide me further strength and cability to sand the borders of the box to make them rounded. This will ease the glass/carbon fiber positioning.

I’ve used glass micro ballons to thicken a bit the epoxy (the one I got is pretty fluid even at 18°C) and I’ll be able to report tomorrow.

Nothing to worry on the dirty cells, it was just my stupidity to use some high temp silicone, which I have almost removed from the pack.

So Cedric I’m going to take a break and follow closely the progress of your akkubox in airex. And since I still have some 7mm and 10mm plates left I might venture out

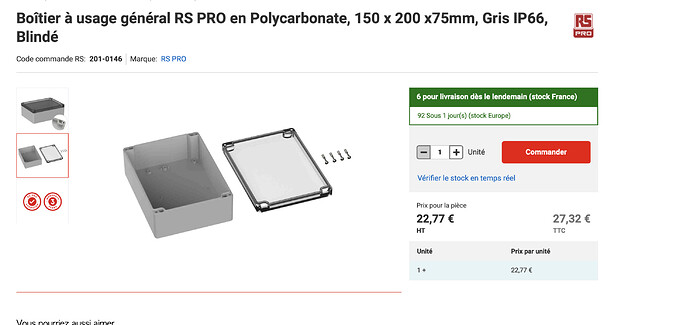

I’ve ordered the 150x200x75 IP66 enclosure and should get it in the next days.

I’ll move on building the battery box. First, the side panels are almost done after one night curing. They are still a bit sticky because of the cure around 15 to 18 degrees but I will be good to go.

Today I’m going to sand them to remove the excess of epoxy and will epoxy them with micro ballons on the bottom panel. Tomorrow I will add the fiber.

going Airex was the right call. I will be saving a lot of weight (and also a lot of time)

Side panels

Panels + top & bottom panel : OVERALL

That’s overall 200g (complete) vs 510g (without top panel) for the structure. It could be even more because the PETG borders are very fragile (not that much support & filling inside)

Moving on with the battery box. Of course, this is less fancy than the 3D printed box but so far, I made little progress by attaching all the panels together with epoxy and microballons cream.

It’s curing. More to come tomorrow morning on the box!

- Bottom panel is 5mm

- Side panels are 75mm (21700 cells are 7cm height so that gives me 5mm of extra space (I know it’s not much) but I’ll adjust later if needed

- Top panel will be 5mm

That will give me 85mm raw material battery box height and 5mm for the fibers (glass & carbon).

It will be a tight fit but should work OK and I have 5mm for adjustments.

At this moment, I don’t think I will go with vacuum but I may change my opinion as I have some clothes vacuum bags that could do the job.

HI okp,

i’m THIERRY54 from east FRANCE and I know you from ESK8 !

I just want to encourage you in your efoil DIY,

I’m interested in efoil too because I have kitefoil and windfoil …

But I 've not your electronics knowledge …

Don’t knoow where I can present myself to everybody and sorry for the little spoil of your post !!!

Do you think we can use 2 tattu lipo 6s 30000 ma to discover efoil or it is dangerous with water proximity ?

I 've got a focboxunity too and my first idea was to make a litte drive assistesystem with 2 800 w brushless special water which will be possible to mount or demount …

I m a litte dispoointed readind all the posts , and before buying something I ll wait a little bit

I send you a message on ESK8 too

thanks for everybody in this forum , manu etc … greats builds

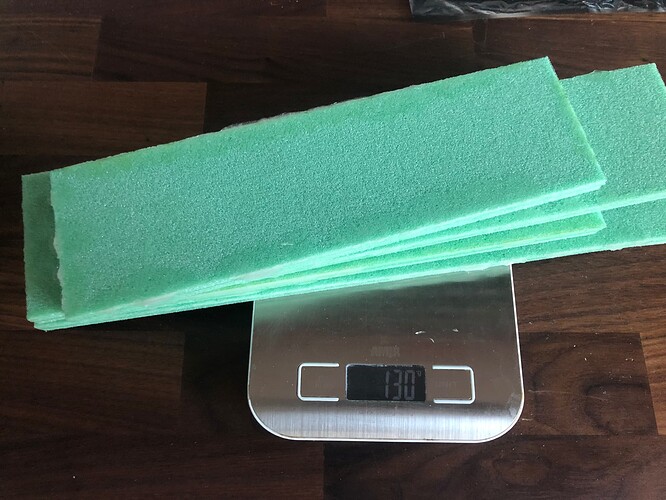

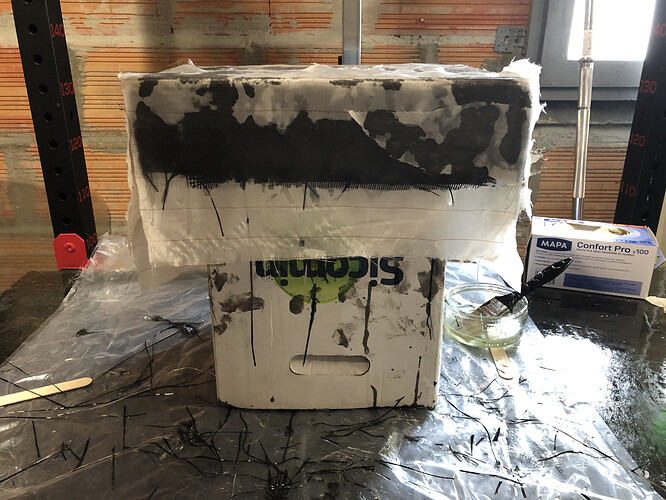

Moving forward on the box. I’ve used several pieces of glass fiber (193g/cm2) with around 120/130g of epoxy resin. Of course, the fact that it’s 16°C in the garage make the epoxy less fluid, but still works very nicely. Drawback is that it’s a little harder to apply because less fluid, but advantage is that the fiber sticks quicker to the part. I will let it cure for 20 hours and then put it inside (20°C).

I’ve reinforced several times every junction (between each side and also between the sides and the bottom panel ) and decided to go for the inside first because I want my box to be perfectly flat, with no torsion (my side panels may not be perfectly horizontal and I’ll fix that later). Putting some weight with square tubes on the top helps while it’s curing.

I’ve also used several peeltex sheets to remove the excess of resin.

If everything goes to plan, tomorrow I will be sanding the extra edges and applying 2 sheets of CF (193°C) and one sheet of GF and I’ll call it a day!

winter epoxy, never tested but the factory is ok , epoxy classic and pu resin allready shipped rapidly

4/5 days for delivery

will test if I start my Efoil !!!

polyestershoppen

Thanks Thierry ! Well noted and the price is very decent. The pot time is very short (15 minutes), so maybe the “rapid” version will be more all round.

Sharing some photos I just took while it was curing. It’s not fancy, but so far I’m pretty happy.

What is nice by using microballons to assemble the walls, is that it’s becomes a white cream and it’s easier to spot where sanding is needed.

You can also see that I’ve sanded the bottom borders to avoid any 90° angles.

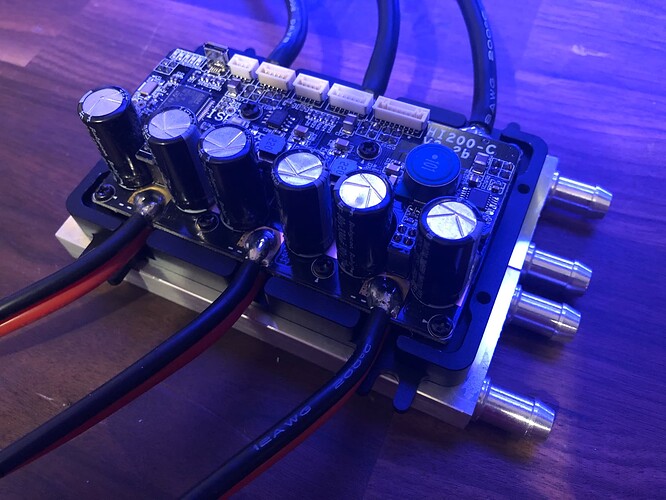

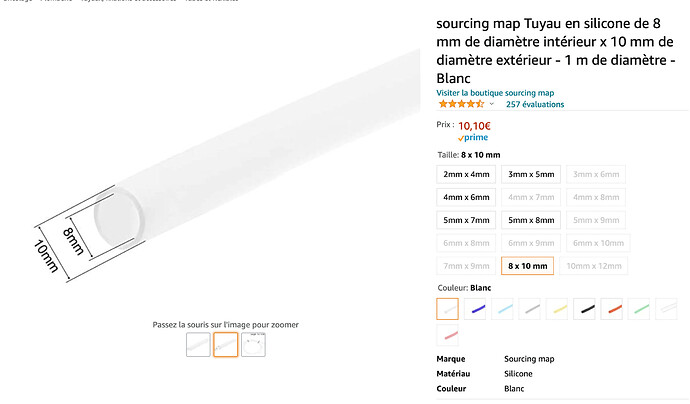

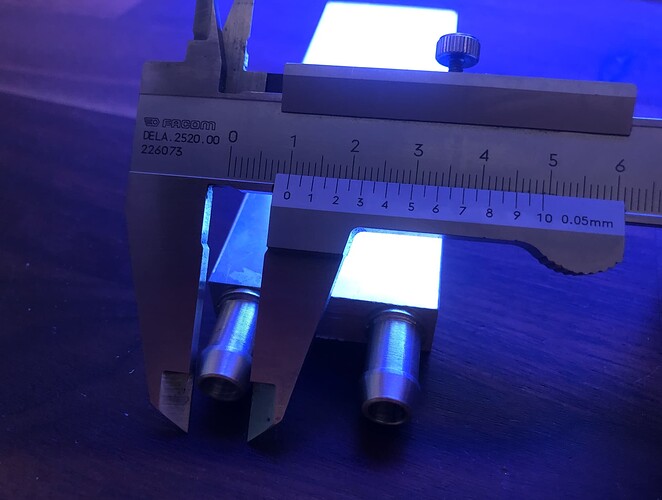

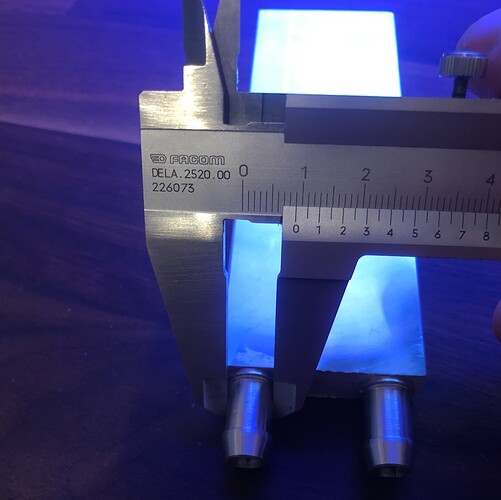

I’m now going to get the silicone tube for the watercooling system.

Should I go for 8mm internal diameter/10mm ? This will give me a tighter fit and should work with a flexible silicone tube. Not 100% sure.

I also don’t believe I will run a 10mm tube in the mast, so I may need two reducers “devices” to reduce the 10mm to something a bit smaller.

Any advices?!

The build I’ve seen seem to have 8 or 10 diameter tube (video compare eflite and lift you see the inside connectors for the water …don’t remember where is this video !!!

will you have a pump for your cooling or passive one …

I will go for passive cooling

good idea i made best experience with.

Hi there,

I’ve removed the peel flex; which was pretty straightforward but still require a plier to avoid damaging your fingers

and after 1 minute of cleaning/sanding; the box internal part is done. It’s becoming very rigid although the other side of the Airex/box has not undertaken any epoxy/fiber so far. That’s the next step.

The peel tex technique works fine, even without vacuum as it absorb unnecessary epoxy resin whenever needed.

I don’t know how heavy are your battery boxes guys, but so far, I’m reducing it as much as I can. Of course, I could have gone with 5mm airex and aramide or carbon UD; but all in all, this seems to work nice.

Next step is to do the outside of the box:

- 2 sheets of 193g/cm Carbon fiber (maybe 1 would be enough but I will go overkill here)

- 1 sheet of 193g/cm Glassfiber

And I’m done.

Looking good so far! Out of curiosity, why are you you adding the 193g/cm Glassfiber when already using CF 193g ? To my very limited understanding of composites, this will mainly add weight but does not add any practical strength or stiffness in combination with CF?

Thanks mate. I’ve added the GF at the end to enable a perfect sanding and “more material” (with finer weaving) that will help me to constrain the CF to move in the curing process (especially on the borders where is not so easy to have a perfect bond) but also to enable a more glassy finish. I could have gone with all CF like you said that would have worked well too.

Some ugly photos as the process without vacuuming is not so sexy.

OK, now i get it! Those outer corners/edges… i always feel its a challenge to get a nice tight finish without bubbles what ever material and matrix used, so much easier when using a mold.