Are these 3d printed?

The FR is alu, while the VS prop is printed with PLA. I tried print it with PETG, but was too brittle. As you can see the PLA prop has lost some material, not sure why, maybe hit something in the water. It’s not very strong though, and one of the reasons I would try an alu prop, but overall with some treatment (I pour epoxy on it for a smoother finish which adds some strength) and improved 3D printing techniques, this model and it’s folding cousin could be close to ideal for this motor. My top speed is 29.9 km/h on 10s battery and 1400cm Gong Fluid foil, which I find amazing for a 105kg rider on this tiny motor!

@bbe thanks a lot. Where can we get the fusion360 files? Would like to try for my 65111 flipsky motor

Thx!

Tried the FR 2 Blade 7” on a 63100 with 12S. It works but I think the blade surface is a bit too big. Current was higher than with a 3 blade flight prop. I also tested a rather small 800cm2 wing with this setup, that also increased the current. So, no scientific testing…

Nice to know. Then the 3 blade will be an even higher load on a smaller motor. Sounds promising…NOT!  Well, I use a 6’5 big board, larger foil and lower kV so by going gentle on the throttle I should be able to get foiling and after that, the current is no problem. Is your blade very sharp too and do you think there is any loss in performance to blunt it?

Well, I use a 6’5 big board, larger foil and lower kV so by going gentle on the throttle I should be able to get foiling and after that, the current is no problem. Is your blade very sharp too and do you think there is any loss in performance to blunt it?

The trailing edge is thinner than that of the flite prop (which is from plastic). As the FR prop is hard anodised, I would not mechnically alter it. The oxyd layer acts as corrosion protection. The prop is also balanced, so you need to keep it balanced when you alter it.

I tried a flying rodeo 7” 2 blade prop on a 120kV 65161 with 13s, and it used significantly more current than the manta 3 blade. I was expecting the FR two blade to be efficient, but it wasn’t. It also seemed to cavitate or slip a lot, with poor thrust.

I have similar experience with my fr 7”, slip and cavitation. My flite prop runs better actually.

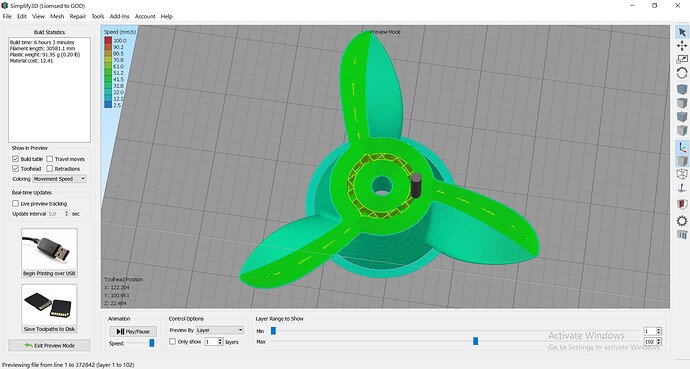

I’ve been playing around with a few prop designs including the @V_S 6.7inch prop printed in PETG. At 2600rpm or higher I get really weird spikes in my motor and battery current (constantly up and down between 30 and 60amps).

I’ve been playing around with a few 4inch pitch designs to create more efficient cruising but keep experiencing this issue with all my props (all 3d printed, PETG) at rpm over 2600.

I can cruise at 18kmph on the @V_S prop with only 18a battery current and under 30a motor current. Only around 50% duty cycle though. Do 3d printed blades need extra support to handle the higher rpm? Happy to share my prop design once I’ve tried a few more!

I don’t know how thick the v_s prop is but in general a reinforcement layer is needed to make the blades keep their shape in loaded condition.

One or two layers of epoxy can also stiffen the blades somewhat.

I usually have applied two layers of 100g/m2 UD carbon on the props that i thought was worth it. With that the blades are so stiff i can’t bend them at all.

hello…

I print my propellers with pla but i dont have problem with strenght and braking.

i suggest to print propeller with as much as wall thicknes unthill blades are all walls.

Printing like this you wil have much stronger propeller and print quality will be better.

ike this

Hi Alex , it would be so cool if you could share your adapter, I also have a 6384 and fliteprop.

Here is my adaptator. It is far from perfect and you will have to check your printing tolerances with the bolt.

Hi alex , thank you very much but for some reason I cannot open the page, maybe you have to renew it?

Hello Riversurfer this adapter looks really great ![]()

![]() would you mind to share it? That would be really cool. Thx a lot

would you mind to share it? That would be really cool. Thx a lot

I have already shared it, see post nov 22

Sorry , thx for pointing it out. did not see it before ![]()