what hardware are you using for the lid? hinge and fastener?

i user those hinges: Amazon.de

fastener: https://www.amazon.de/gp/product/B07G4QMPR5/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

the lid i think about a Siebdruckplatte with 2 layers CFK.

As seal for the lid i using https://www.amazon.de/gp/product/B07VX69WNC/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

The seal goes around in that gap.

Here you can see the part around the fastener. The fastener ist not waterresistant, that is why i mount theme outside the seal and box.

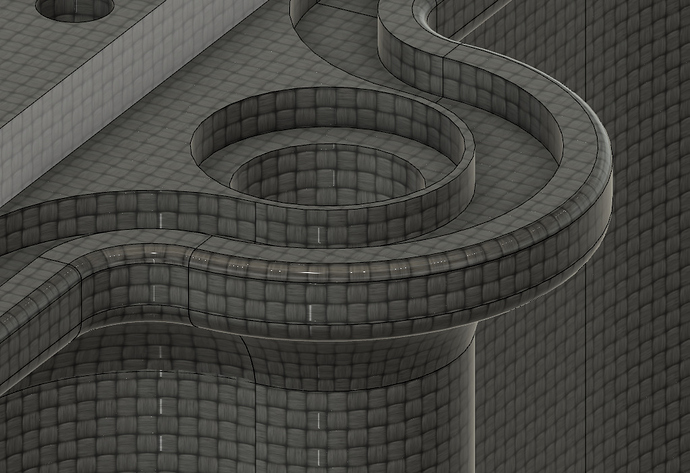

On the weekend my last big print was finished. Printingtime more then 100 hours ( Chiron only count 99 )

Now I must remove the support inside and than I can put both Parts together

Looks good man! Witch board is that?

It is an prototype what I bought from that Startup:

… in the last days i have less time for my efoil project. I try to make a arrangement for the Electronicparts in my box and was not happy.

So I decide to construct and print something to make 2 levels.

On the bottom level will me now all connectors for engine power and the water.

Also on this Level I will mount the water pump.

On the top level I will put the rest.

I will construct some devices for better mounting all.

I also made some improvements inside my Akkuhousing. The risk of an short circuit when I screw on the contacts was for me a little mit to high.

So I constructed some caps to put theme on the Amphenol sockets.

Very nice compartment! However, be extremely careful choosing those round hatches. Mine was technically waterproof but it leaked a lot and I had to seal it permanently. The supplier said that while it is water resistant… It is not waterproof when submerged. So if I were you, I’d try to test the round hatch you have before installing it.

Very nice project. Since the box strength is unknown, as a stress test will you stand on the box mounted to your hydrofoil laying on the floor before going to the water ?

Yes, before I drive, I will test the Amphenol Connectors and also the box.

The box are mounted inside a own area that is closed itself with a lid. I make theme waterproof.

So the Akkubox is a second secure level and I hope that water never will come inside that space and when, I do something plus to be saved!

Before I do those tests, I must finish the printed housing from the Akkubox. I will be laminating it with 1-2 layers CFK and epoxy. I think it will be strong enough to stand on it after.

Some updates…

I finished my Akkubox. The box should be waterproof but on my first test the water coming at the screws inside. I can fix that easy.

Also I begun the Technicalbox.

Great job on your build.

This is such a good forum. So many creative people. So many different ways to build an e-foil board.

However, one thing is always the same… It is so much work!!!

Looking good, hang in there! You’ll be flying soon!

what type of silicon tube and what tube connectors do you use?

Looks like pneumatic fast connectors?

Greetings from your neighbour city

Look inside my Buildthread. I wrote all about the connectors and put Links.

What you mean with the Siliconetube?

From which City are you?

Greetings back, Robert