You can open one and count, or you can use an ESC that counts them (like the ARC200). I’ve done both.

Yes the 65161 is much messier than the FR motor but I guess you get what you pay for. I’m more surprised I haven’t been able to find the manufacturer of the FR motor.

But his boards might be available again through Chris in Canada soon…

Why would you ? The company making this motor will more likely only sell it to Flying Rodeo. They won’t sell it to anyone else, David sure have the Product’s exclusivity, otherwise Lift would have bypassed him long time ago

Lift had their direct drive first, so FR either located the manufacturer or reverse engineered it and got his own made. Either way it was after he bought the Lift board that he changed his design from a gear to a direct drive. Lift might very well not be buying the motors from David, but directly from the manufacturer. All we know is that they are the same motors.

I’ll give you that. However, if you look back at FR’s Instagram when he was still running a geared drive and teased his direct drive motor, he said “patent pending design”. What I think is that David indeed reverse engineered the old Lift motor and then asked a company, pretty sure someone he knows personally, to manufacture it. He of course owns the motor design because he paid for it. This way he would be the only one to sell it.

I think the first generation of Lift foils was using the motors from Reachertech / Flipsky /…. They were buying it directly from the manufacturer. Once they broke the contract with him, the manufacturer started to sell it to other companies.

This is only my 2 cents.

No that’s not what happened. The original Lift motor dimensions are different to the 65161 motor and also have a different internal design. They are very similar to the FR motor dimension wise. Anyone can say ‘patent pending’ on any design, but that patent depends on which country its based in…

In a SupMike link, found some connectors used by LIFT from the German manufacturer ODU:

Electrical Surfboard Hydrofoil

The Hydrofoil electric surfboard from MHL Custom/Lift Foils requires a connection that is highly current-carrying. At a top speed of up to 40 km/h, it must also be vibration- and shock-resistant. Furthermore a corrosion-resistant connector is required which prevent the ingress of water.

With a current carrying capacity of up to 2,400 A the ODU LAMTAC® is the perfect solution. The lamella slats result in a large number of contact points that create a reliable connection. The customized solution of the ODU LAMTAC® is applied between the speed controller, the motor and the battery. This allows the controller to be operated.

ODU MINI-SNAP® Series K is used for secure transmission of sensitive data between the battery and the control unit. In this application, it is characterized by high reliability, a robust metal housing and a high level of sealing.

Can we buy this battery pack ?

Do you have a contact with them? I try to inquire on the website, sent emails, even what’s on his phone, no respond.

I want to buy one of those.

Try him on the forum at @Flying_Rodeo ! He is a busy man! A friend of mine bought a motor system recently so I believe he still sells them!

I remember to have read that a forum member tried in 2019. They refused. Maybe have they changed their minds since

Lift and direct-drive Flying Rodeo owners might be interested in the story of woe of motors that let the sewing machine oil out and the saltwater in. Saltwater intrusion in an electric motor = catastrophic loss.

https://efoil.builders/t/lift-efoil-motor-wanted-to-buy-used-or-new/10116

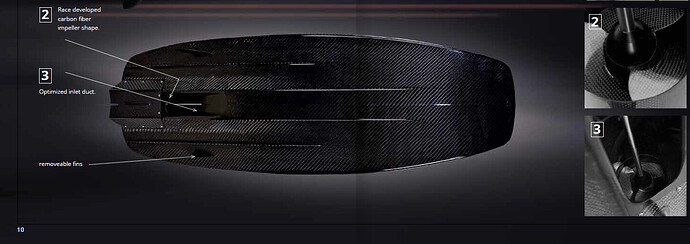

Lift released version 3 and seems they are going to release soon an Elite 3 version with carbon prop… anyone seen it? Always thought it was the way to go for best performance. Petrol jetsurf has a really thin carbon impeller.

Maybe a carbon propeller is cheaper to produce than an FR propeller made of aluminum alloy (CNC machining + anodizing). However, it is always the case that the most important thing about a propeller is the shape of the blades, the number of blades and the shape of the hub, depending on the performance type of prop. Only second is the material used.

I don’t think a carbon prop will be cheaper than an aluminium prop. More labour, most likely will have to be prepreg and probably high modulus. For small prop like the one we use blade thickness is super important. Carbon allow to keep blade stiff while thin.

I recently modelled a propeller with three removable blades in 3d CAD. The blades can be carbon laminate or high quality aluminum, the hub will be high quality aluminum. On this project it will soon be easy to see which blade material will be cheaper and which blade material will be stronger for bending.

Yep made removable carbone blade in hub before, I had better result molding carbon prop in one shot. Blades were breaking where they entered the hub, I had to use high modulus UD for it to work

It’s admirable that you were able to make that type of propeller.

I think it’s easier to make a wing out of carbon. Have you tried it yet? Or do you prefer to use a commercial wing now?

Sorry what do you mean by wing? a foil front wing or propeller blade?

It is quite easy to mold carbon prop blade as above but I found out if you really want a gain in performance it is hard to make them thin and strong enough with this technic, they tend to brake at the hub where they are inserted. That said I was using printed mold, I might give it another go and cut aluminium molds when the CNC machine is free. I think the trick is to increase the root thickness where it insert in the hub, like 3-4mm thick where it enter the hub down to 2mm at the blade.

Jet surf impeller: