In this case with the FR style prop, yes definitely too high. It will never have the torque to reach max RPM.

Without having measured the motor, such statements about torque are nonsense!

It’s not nonsense. You can already see from the stats that it will have less torque!

It can handle less power and runs at a higher KV than the FR motor.

The FR motor has also maximised the stator Vs rotor size and poles to create the maximum amount of torque for its size.

Unless this new motor has some extra magic fairy dust inside it, it will not have the torque characteristics to push a 6" 150mm prop to 160kv.

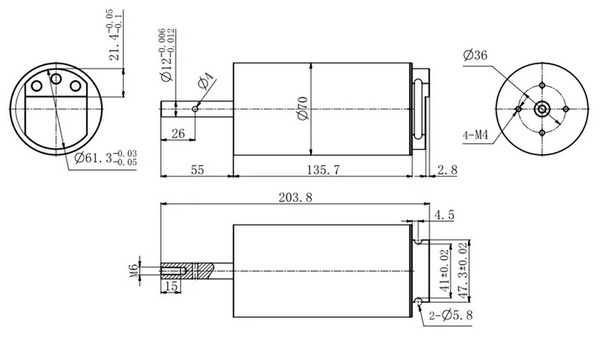

Yes, a motor off this size and kv can never have enough torque to get to it’s max rpm with a prop like that. @55V this motor should do 8800 rpm with no load. 5.5kW is maximum power rating. If you calculate torque with those values you will get 6Nm.

Without knowing the winding scheme, magnet structure and some other factors, such statements are not good.

Who the manufacturer z. B. indicates less power to stay on the safe side without damaging the engine …

Clear results can only be given on a test bench with an eddy current brake!

Greetings Frank

FR’s motor is 67x135 if I remember correctly.

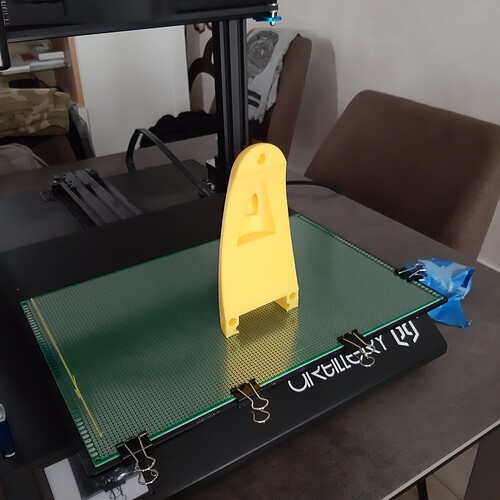

Honestly I don’t like the design lol. Hopefully you guys are going to like mine as it is a much cleaner one

So, to be fair, for this size, anything above 6500-6600 is not efficient anymore for 16 poles motor. We ran some design before choosing our actual form factor. With 16 magnets the frequency at 8000 RPM will be 1khz. No lamination material available on the market can work with good efficiency above 500hz.

So, this motor is not 16 poles. Maybe 10 or less, which also means not that much torque I guess

Are you designing a new motor? If so, I be intrested to test it if you can make it before this summer?

I am, and will soon start a new thread about it.

I am targeting April - May fo the first batch and June - July for the second one. Will post all the details soon, stay tuned

@Demis did try this 70136 equivalent from Eagle Power.

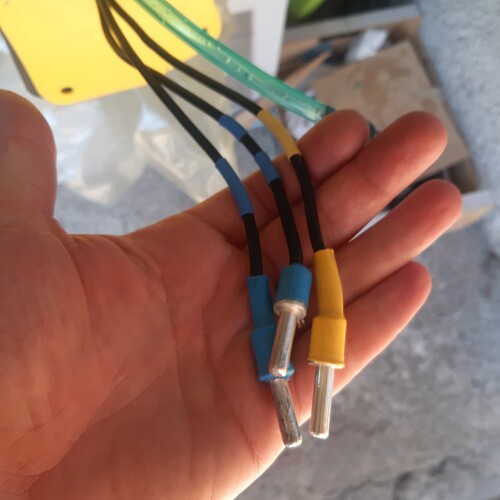

Here: Lift motor wire connectors? - #8 by Demis

A tragical end unfortunately, hey @Demis please comment ![]()

I bought this PA70-150 220kv motor I made the connections with esc my first tests were in the pool with a 20 Ah battery pack and the result was very bad, the motor was too busy the battery was too small for the power that the motor had asked and the awg12 motor cables were burning, I am also attaching a video of how the esc cut the current for protection in 4 seconds, I bought a 48ah 48v battery pack it seemed to work but when I put it on in 5 minutes the engine has stopped turning, I opened it all burnt, if anyone has bought and is using this engine, can you tell me how they are using it thanksProcessing: 20220613_152028.mp4…

500hz is nothing, what do you mean? There are lamination steels that are razor thin if it’s needed.

Did you run it for 5 minutes in or out of the water?

This motor looks exactly like the lift motors.

in the water at 50% of the command the propeller got stuck and I went home I opened it and saw the damage

Is this motor really waterproof ? Do you have pictures of the seals ?

I used red rtv for sealing threaded cap where the cables come out and rear cap with 4 set screws, no water, I think the supplier did not put mineral oil inside and stupid me not to ask him why once opened no oil came out , the engine is brand new, it only has 5 minutes in the water I tried a lying acceleration at 47% of the command and I think I would have reached 40 km / h, I was about to go ashore to take the go pro with gps to record the speed and I heard that the engine was not running anymore, arrived home I open the engine in 5 minutes and I saw what I never wanted to see, all black, a smell of burning all here, now I have ordered a fly rodeo engine let’s see if this engine it makes me happy while I’m designing my third pro board

Moved to Kedean zone for history purpose.

This is a different motor to the PA70-150