It all started in 2023 while visting Turks & Caicos and seeing my first two Fliteboards. Once I was back in the states I starting pricing them and found out real quickly it would be out of my budget for a weekend toy. I kind of gave up after that until I joined a few Facebook buy/sell groups and ran across a post talking about this forum. Once I started reading through the builds I realized this was my ticket so here we are. Goal was to try and stay at or under $2000usd

V1 Fliteboard 100L - via Facebook $500

Aliexpress 65cm Alum mast, Carbon fiber 2100sq in front wing - $331

10s 11p Battery already built from Jag35 - $314 shipped

Flite Prop -$45

Flipsky watersports kit (65161, 75200, Vx3 remote, bluetooth and antenna extender - $622

Icharger X12 - $183

Amazon 12 ac to dc converter $30

2.75" Carbon fiber nose cone $14

Total Build $2040

I had some help along with the way with a friend owning a fabrication shop having 3/4" aluminium already on hand not charging me for cutting out the adapter plate

created by @MBard and another friend that just bought a 3d printer that agreed

to print the prop guard for free just to test his printer.

Fliteboard recieved

Foil setup recieved about 1.5 months later

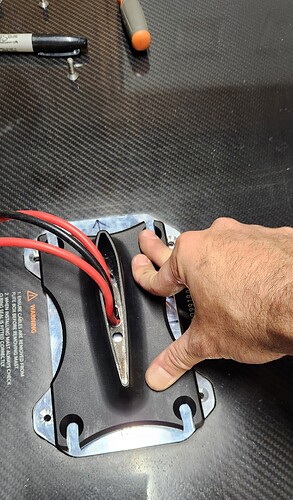

What started as 3/4" alum plate and using a cad file @MBard posted in his build ended up as the adapter plate

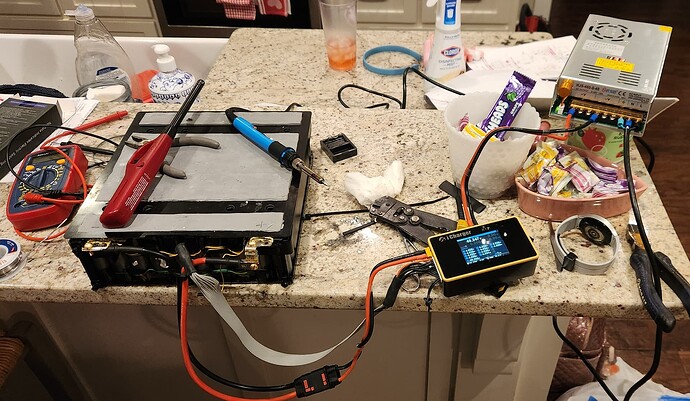

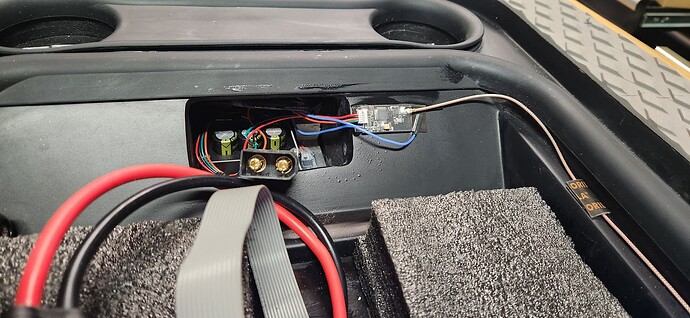

Battery arrived, disassembled, balance leads, inline fuse, 8awg wire/connectors added then shrink wrapped. Yes I know its not “waterproof” however its “water resistant” and thats good enough for me for now.

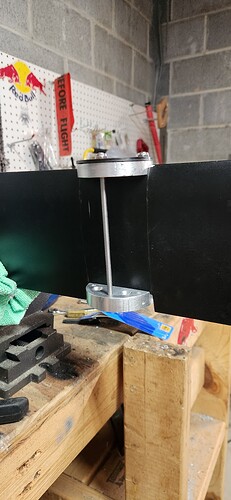

Mast was notched and motor mounts were cut from the alum plate and turned on a lathe to 2.5". I forgot to take more pics at this point. The rear mount was notched for the motor wires then center drilled for m3 screws to attach to the mast. I didnt think these tiny screws alone would withstand the torque so I added some stainless all thread on each side.

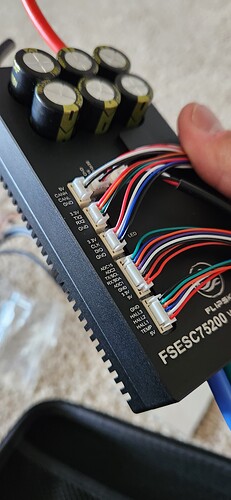

Motor/esc/remote arrived

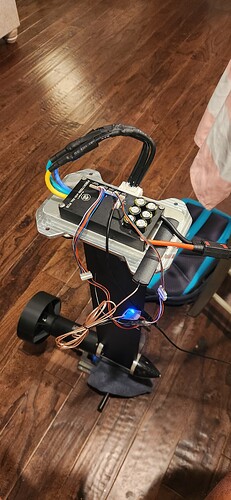

Motor mounted, wires ran and esc mounted to adapter plate. I chose not to make an incloser for the esc or battery as the fliteboard seems to be sealed very well. I sealed all the holes in the mast top and bottom as well as the wires with 3m 4200 as I already had it on hand from previous projects.

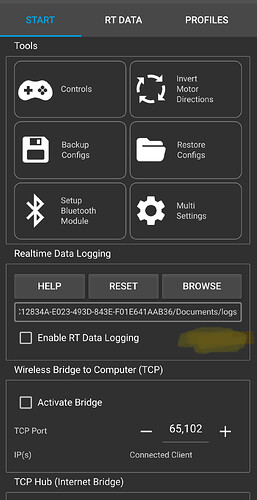

Pool testing/programming the esc

Leak testing the board/adapter plate before final assembly. I left it in the pool for over 24hr while pouring water on top etc with no leaks.

All that was left at this point was to make some side skirts. I had a couple printed but they were flimsy and ended up cracking so had some carbon fiber and fiberglass on hand with epoxy resin. Using a piece of 2.5" pipe I laid out some fiberglass then couple pieces of carbon fiber making the side pieces. Once cured I used a template I traced of the mast to cut the arches.

Some random pictures

Maiden voyage yesterday. I still have some bugs I need to work out as it wouldnt get over 7mph while standing or on my knees and the amps were constant at 100-104a. After reading and asking Im thinking the prop gaurd may be the issue?? Also not fully convinced its not a VESC tools setting. I dont have a log yet as I will need to go back to the lake and create a log file unless I can hold it in the pool long enough to post a log. Thoughts? Also on the side skirts are people sealing them to the mast to reduce drag even more?