Is anyone using 21700s? Seems like a 14S 10 or 11P 21700 battery would yield higher potential discharge rates with comparable weight and AHs to a 14S 14P 18650?

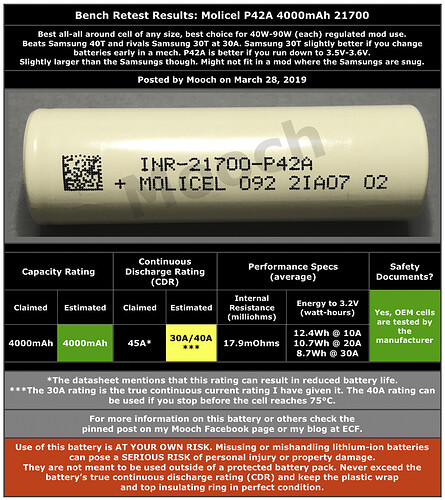

I got some molicel p42a batteries that according to the mooch can do 30a continuous. Could probably do a 14s5p battery but I’ll probably be making a 14s9p or 10p this winter so I can get hour of flight time.

I have a set of 20700’s which works great compared to the 18650 version. A lot less hot and obviously a lot more range.

Same technology and energy density so you don’t really see any advantage at all. The decision to use them would simply come down to what battery dimensions you can have.

Yeah, and also when packed tightly, the total pack energy density is not too much different between 18650 and 21700. However, it seems that modern 21700 packs usually yield better Wh & discharge capacity numbers when rated against 18650 packs. So their improved capacity outweighs the slight increase in cost. I’ll probably release an excel comparing market options for 14S10P 21700-equivalent packs made of different cells at some point, but that’s unfortunately not release quality yet.

Another advantage of the 21700 pack is that you have less work to do when building the pack. The amount of spot welds adds up quickly. Now with the relatively inexpensive P42A and super inexpensive Tesla 2170 cells, I will definitely go with one of those instead if 18650.

the best 21700 cells can handle around 25 A short-term loads and 15 A continuous output. the best 18650 can briefly deliver around 18 A and permanently 12 A. at an ambient temperature of 20 degrees Celsius. the maximum temperature of 60 degrees Celsius is not exceeded here. if you want to build a battery quickly, the 21700 cells are more ideal. if you have high peaks for a short time, the 21700 cells also have more mass. that means if you eg. only 30 seconds an xtreme power start is very possible with 21700. It is important that no data reports are used where cells are tested individually. with e-foils, a pack has different values because of the heat dissipation.

Where have people done pack test on cells? Did you test similar AH packs between 21700 and 18650?

Barring that, I think is fine to use the individual cell tests to get a ballmark estimate on packs (or the datasheets). Most of use are building to capacity rather then raw max current anyways.

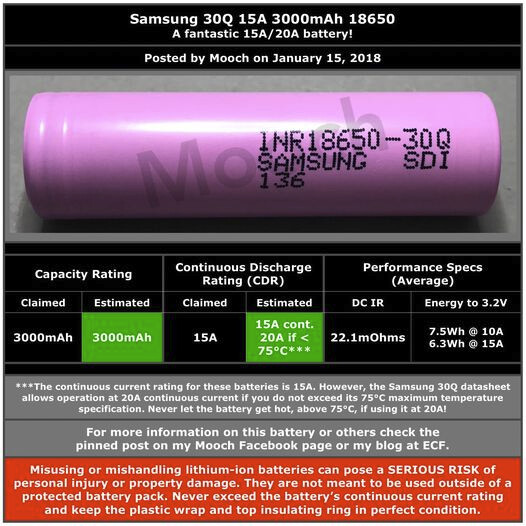

12S12p 30Q is 36Ah and 180A continuous (~7kg weight in raw cells)

12s9p p42A is 36AH and 270A continuous (~7.5kg)

Even derating that you are way under both. I’m probably 20-60A on foil and maybe 100A while getting up on foil. And that is probably good for capacity either way since you’ll get more capacity the lower the current draw per cell.

Maybe I’ll take some thermal pictures when I get my p42a pack done and can foil back to back with the 30Q (in the spring).

Are you talking about 18650 21700??

nice data sheet, so +20% IR for the 30Q, +40% wh for the P42

there is not much to compare here , about the same price at the end for wh

just a different way to make a battery, but for a high speed efoil, i would go for the p42 for sure ( big pack)

The best way to compare these IMO is to figure out a pack size (in Wh + voltage) you need, then look at actual discharge Wh from Mooch and plan how many P cells you need of each cell variant to reach your total goal. Then compare total cost between your options.

You can extrapolate discharge Wh to the discharge rate you need. Its not absolutely accurate but usually Mooch gives two data points and extrapolation is our best option. This also needs some manual iteration because discharge rate per cell changes based on cell count, so Wh per cell count is not linear.

I am personally waiting for discharge Wh tests from Mooch about the Tesla 2170, so I can decide between my current cell options. After this, I’ll release my excel files as well

i have the hobby of electric flying with a motor paraglider. and also fly on the water with my e-foil. with 15 S batteries. I have been building batteries for about 6 years (not all batteries for myself). 18650 most Sony VTC series, LG, Samsung / 15 S / 10P, 15 S 12 P, 15 S 16 P, 15 S 25 P. 21700 Samsung 40 T, Molicell, 15 S 8 P, 15 S 10 P, 15 S 20 P, 15 S 30 P. the applications range from standard loads to extreme loads for the test. I did a lot of tests with thermocams in order to see the temperature curve through the housing exactly. my statements about the different cell types arise from these experiences. I know the Mooch site very well, of course.

Do you have a build thread of your epowered paraglider?

I have had really good results with various sony VTC cells and high power applications.

there is no construction tread. but you can find me on facebook under thomas brandstetter customparamotors. or under youtube with my name. all manufacturers in aviation and ultralight use the sony vtc 6 cell. because it has the best performance in terms of life and capacity. however, we load the cells with a maximum of 3 c over the long term. In general, I think nothing of nickel strips connector. i have been using pure copper connectors for years. there are now series hybrid nickel-copper connectors for sale in asia. if you don’t want to solder or if you can’t do it technically.

Hi, im really new in this, and i will do a very basic question to get familiarity, what it is the reference for, 14s 10p, i do know that and what would be the result, if put 70 of this in a pack, the mah rise? what would be the standart ride time with a sssmotor

Do you have any suggestions on a seller for hybrid nickel-copper connectors to fit 21700 cells (I can only find an alibaba high qty seller)?

What’s the consensus on spot welding a nickel strip on the parallel direction, and then soldering a copper wire on top of the nickel strip in the serial connection between each cell - does this heat up the cell through the nickel strip as much as soldering directly to the cell?