Side question: how can I post without “replying” to any particular post?

Here another paper on ducts:

There You can see effect on various profiles and also the length of the duct. Think recommendation was 40% of diameter, but obviously then protection is also less then. My favorite style would be RICE.

Juha and Lien,

I live in Boston but my son lives in Berkeley. This is a very nice design. Juha when do you expect your gong mast. I have one and could measure it if you will waiting for a while. I am also thinking of making the clamp with a small space for a layer of rubber roofing. It is about 1/16" thick and the hope is that it dampens the connection and makes for a quieter motor while running? This looks very promising,

Does the brass tube go straight into the mast or to your route around to the side? Will you put a hose in the mast or simply let the water go up the front opening? The back one looks big enough to fit 3 wires by itself.

George

I live in the SF bay area, but my daughter lives in Boston!

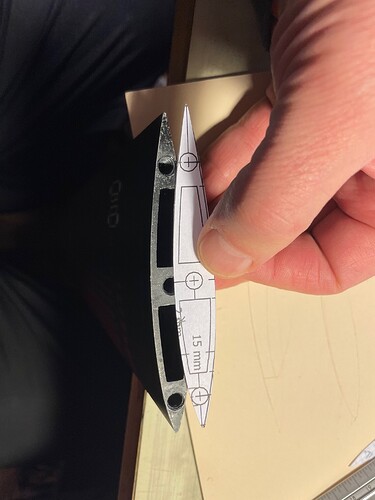

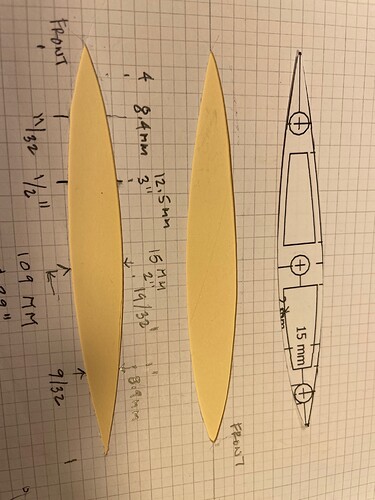

Hi! Thanks @Kiteman54 for offering to measure it! That would actually be very very helpful. Would you be able to trace the outline of the mast on a piece of paper and scan it, and also measure a couple of the important dimensions, such as thickness and length (front edge to back edge)? Those measurements will allow me to properly scale the shape.

The brass tube will be epoxied into the small U-shaped holder piece that you can see on the front part of the mount. The tube sticks out between the legs of that holder, and I am planning to run a flexible silicone hose from there, through the side cutout in the front mast mount, into the mast near motor cables.

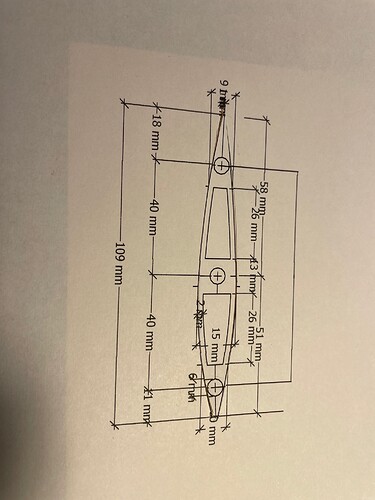

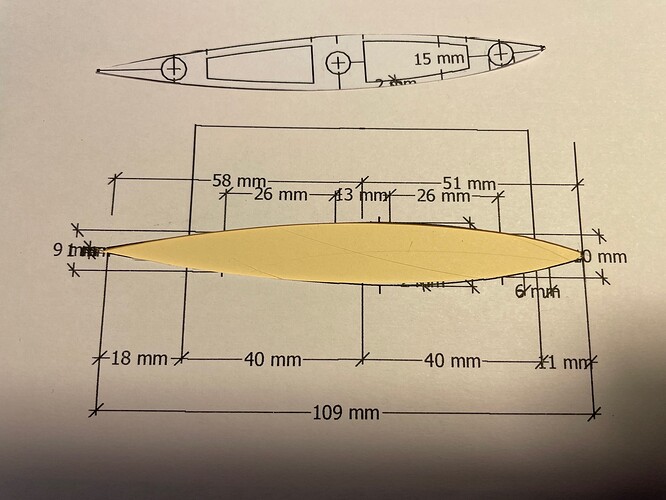

The cut out is on 1/8" graph paper. The dimensions are in mm and are pretty accurate. I sliced the profile using the mast as the template. Good luck and let me know how it goes.

The bottom line is, we won’t be running an open tube prop. What we do need is a prop system that has a smooth taper from the 65mm to 0mm (I have the files for a promising candidate). If someone could take this prop and make some changes on the blades. Maybe in small increments so we have the ability to print, test, and compare real time results.

I’ll start another thread to that end… and we’ll see what happens.

We’ve got to put together a library of printable files that are proven to be the best available parts for our sport/s. A proven parts list with suppliers info would be great as well.

We have all spent too much time searching the net for parts and information…

I do, and the amount of misleading specs on the net as well as false claims by unscrupulous sellers is why there should be a searchable library of proven information and printable files…

No idea what this has to do with your wrong opinion of the rpm topic. My Flipsky motors, 120 and 100kv, operate as expected. The values match with the theoretical approach regarding top speed and rpm.

I have a couple of printable props ranging from 6" to 8" , two and three blade which work fine for 100kv and 120kv on 12s. If you spent too much time looking for such just let me know and I can send you the link (files are already public)

But that’s part of the fun… (the design process). Keeps us out of trouble when not in season…

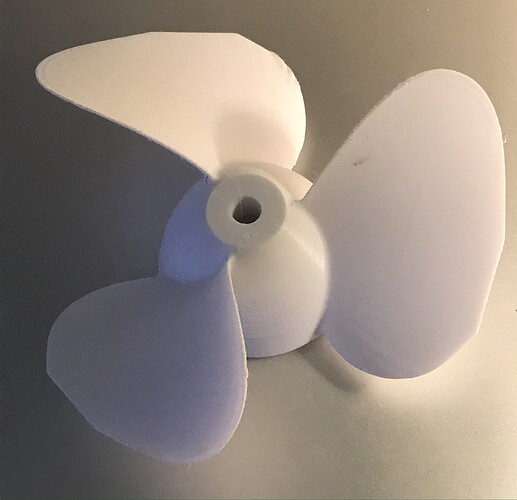

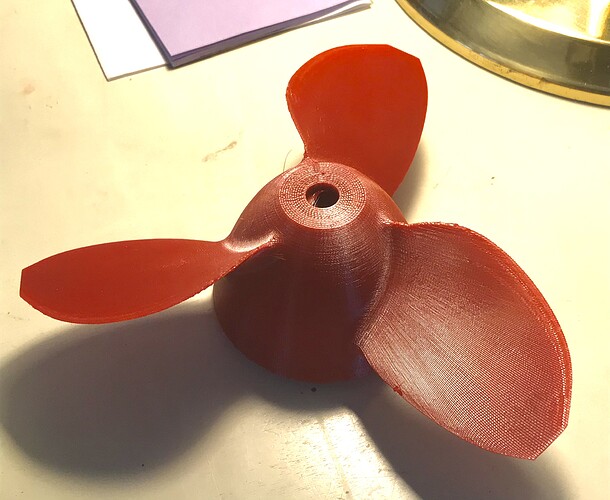

Compare the propeller I got after modifying the operating RPM from 3600 to 3000 in JavaProp. Looks a lot more like a marine prop.

3000 RPM

3600 RPM

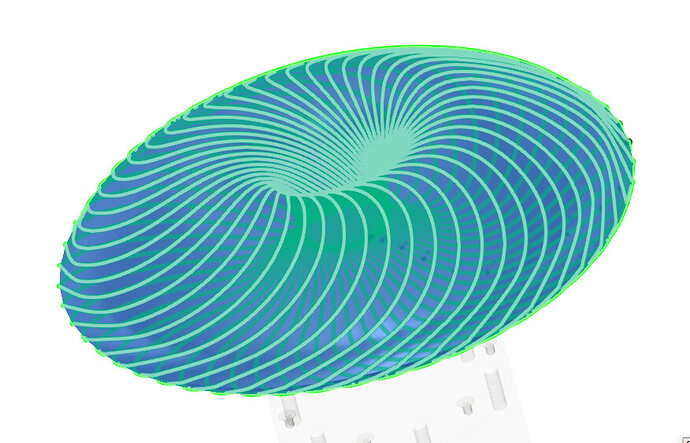

Can’t resist sharing this beautiful pattern you get by sweeping the propeller blade 360 degrees. (that’s the feminine touch mentioned in the title of the post).

I’m using the shape to make sure the prop doesn’t intersect the duct spokes.

Im getting ready to start my first efoil testing this spring. I cant wait to print some of your props. Are you designing any of your props for the 65162 12mm smooth shaft?

Has anybody tried the salt baking annealing technique to strengthen the Props?

Mine is the 65162 with the splined shaft, but I can easily modify it for the smooth shaft (which looks identical to the FS65161 shaft). Let’s get in touch when you are ready to print and test, by then we might have more breakthroughs on propellers.

In the meantime, here is the “smooth” propeller hub without blades, so you can print it quickly and see if it matches your motor shaft.

Here is the hub for the splined MTI65162 shaft, but I think I’m the only one using it. Not sure if the plastic splines will resist the torque. Buying the splined model was a mistake…

Supports should be straight as the water coming is straight as well. It would add more drag to have them at an angle to the water direction because it’s trying to turn the stream of water. The prop screws its way through the water at speed and needs as little turbulence as possible on the intake side. How the prop handles angled spokes would be an interesting test. Having the water spinning before it gets to the prop, might be good might be bad. Thought about it myself a couple months back when I printed mine. I haven’t seen much as far as field testing angled spokes. I would stick with the straight spokes until more evidence of an advantage is available…

That makes a lot of sense. The propeller blade is designed for a specific angle of attack. Rotating the water before it hits the propeller would defeat that purpose.

I agree it’s fun for you, me and for many of us.

Wouldn’t it be nice to pick out all your parts. Put your board together. Test the board and tweek it to suit your riding style. Same situation except you’ll be riding in 8-10 weeks and more focused on changes that you find you need to make as you ride your board.

Can people point me to a few good builds as far as mounting the foil to the board and the waterproof “box” for the electronics ? Seals etc…

For my first build, I have a large windsurfer board that I am planning to cut and epoxy/fiberglass or whatever is needed…