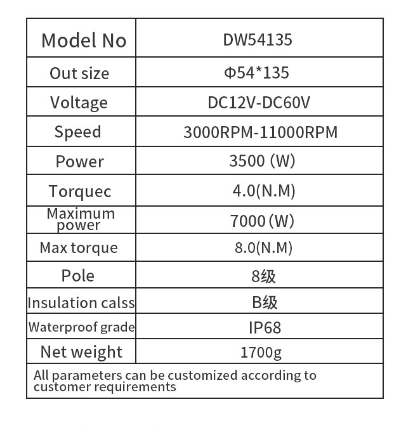

We have developed a new propulsion system for the hydrofoil (consisting of: 120KV motor, 14S 150A ESC, conductor).

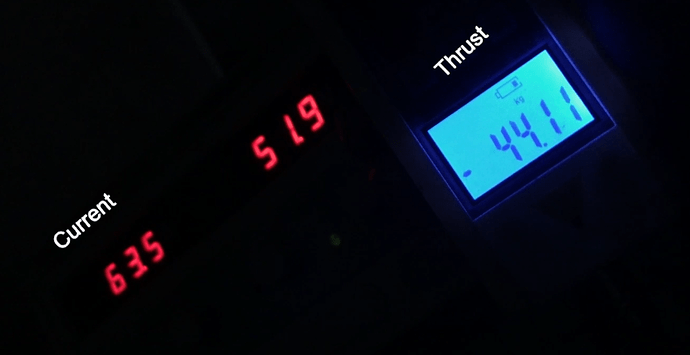

The test results are satisfactory. At 52V, the current is 64A and the static thrust is 44Kg; at 56V the thrust is over 44KG.

The propeller of the thruster is CNC machined.

We are now accepting pre-orders for a 20% discount to our forum friends, if you would like more details or would like to purchase you can email me. (fyk@diamondynamics.com)

What is price for just motor and propeller with 20% discount?

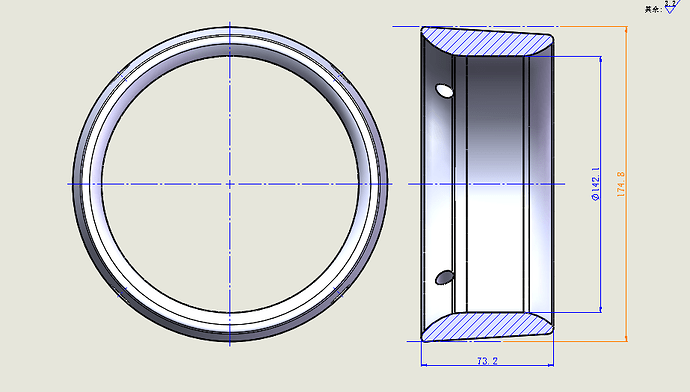

Doesn’t Duct need it either?

Yes without duct i dont need it.

And also can you give little more info about propeller… Diameter and pitch?

Hi, looks very robust and durable, however I suggest a deeper research in duct/prop design. The duct appears way too thick and thus causing lots of drag especially at higher speeds as ducts perform usually better up to approx. 11kt. The rounded corners at the end are also not beneficial in terms of a water release point and less swirls. A conical propeller hub is also more likely to generate cavitation, it has a reason why most propellers have a cylindrical hub.

However, good idea to have a flat side to keep the tip gap even and small.

What is the shape of the struts? Rounded or streamlined?

You might test also without duct, interesting to se difference. Most importantly, You should test this on a moving boat/foil to se how it works in reality. Ducted propellers should be slightly smaller than none ducted so the140 mm seams spot on.

That’s great that you’ve developed it, but without decent information why would people purchase it?

- What’s the price?

- What are the dimensions of the actual motor (length, width)?

- What are the prop specs (diameter and pitch)?

- Can it be purchased without the duct?

Lastly why is everyone making a 120Kv motor when the best motor on the market is 130Kv? Surely if you are going to go through all the effort of producing a motor it would make sense to just try beat the best motor on the market… If you beat that, then everyone is going to buy it…

Considering the KV value, 130Kv is for sure a good proven working value, but is the difference really that critical compared to 120Kv? Would not 0,5 Inch increased pitch even out the that when running 48V? Or if You have a 120Kv with better torque compared to an 130 Kv, the rpm sag under load will be less and speed might be the same anyway?

What is the diameter, length, and weight (motor)? If you have greatly reduced the wetted surface and drag I would expect improved handling and significant benefits gliding with a folding prop with power off on swells. This could be a better solution than raising the motor (foil assist) to get it out of the water? Looking forward to see what someone does with this.

They look rounded to me so not that good.

Is it possible to order propeller without motor?

An agin what is price for motor?

3000 rpm at 12v? WHAT!? It’s about 250kv.

yes, and 187KV at 60V  So it is variable KV Motor!! World news.

So it is variable KV Motor!! World news.

I am not really sure this size inrunner can give 8nm max of torque , Max 4nm seems correct ( compared to a 56123 with 6poles…) but if it can pull 44kg of thrust it is ok as long as the prop pitch matches the needs

Setup won`t work for efoils with that monster duct

Doubtful…no info about the seal and gears? why should we change from a good working flipsky that you can already get for cheap 280$ to un unknown doubtful one?

Motor 120KV。。。。。。。。。。。。。。。。。。。。。。。。。