An underwater propeller has been designed, and the thrust has not yet been measured. Are there any good suggestions for testing these days?

Yes, of course they exist! It is ideal to measure the efficiency and thrust of the propeller depending on the RPM and issue a measurement report with graphs.

If you are interested, I can make this measurement, I have a professional measuring device with very high parameters. Subsequently, I can advise or help increase the efficiency and thrust of the propeller. Only such a procedure will allow this propeller to surpass the Flite, FR and Manta propellers sometime in the future, which are now considered by the forum members to be the best in the world.

@DiamondDynamics is it a pulling setup for a sea scooter ?

Will you make bigger motors and pushing props for the efoil market ? Your waterproof 5490 and 54135 motors are nicely built but seem a bit small for our use

Here your waterproof 5085:

- Plan the test in the next few days. After the test, I will send out the data to share.

- We have a plan for a 30kg pull.

Actually, our efoils need a push setup, not a pull setup.

This requires to flip both the prop (blade curvature towards the hub) AND the duct.

Your duct is not designed for that as the round leading edge should be facing the motor (our direction of motion).

You’re right.This is currently used mainly in rubber boats, robots, etc.

What will be the cylinder outer dimensions ?

There is a market waiting for you if you can enlarge your waterproof motors by 12-15% whose manufacturing quality seem to be above the 65x150mm Reacher/Flipsky/Maytech motors but below the 68x136mm Flying Rodeo ones.

Could you post pictures of an open 54135 inrunner motor so that we can evaluate your manufacturing quality ?

Here is a Flying Rodeo 16 pole - 18 slot motor:

Nice but I don’t know what to expect for an efoil use performance wise.

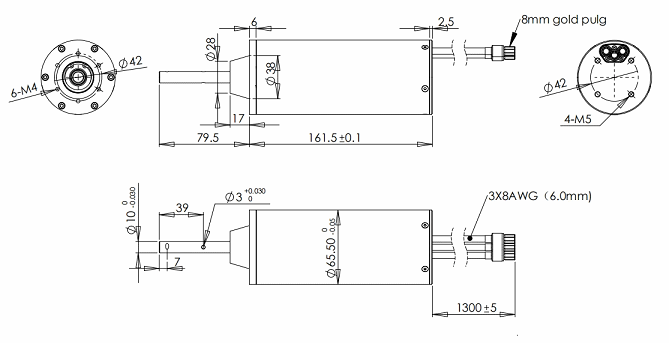

Q1: Would you have the specifications of that motor ?

Q2: What is its total and copper weight ?

Q3: Shaft diameter ?

Same questions for your next “big” motor 30kg pull on which it would be interesting to adapt one of our benchmark propellers (FR, Flite, Manta)

Q4: Would you have the specifications of that motor ?

Q5: What is its total and copper weight ?

Q6: Shaft diameter ? Our main standard: 10mm shafts; here a Flipsky motor

Send it to someone reliable with a Efoil that can test it and report back…

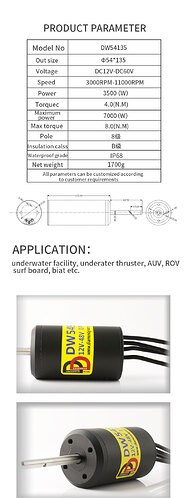

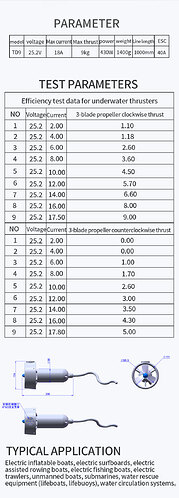

This is the specification parameter of 54135 motor. The 30KG thruster is currently still being designed and improved.

The 54135 motor is used to make a thruster, and it is expected to be tested soon.

I tested this 54135 motor and it’s not recommended. I got a 100kV motor so it’s about 80A to get the 8Nm out of it if it doesn’t saturate already at lower current (which i expect). The phase resistance is a whopping 195mohm and the original phase wires are not sufficient at 14AWG. I replaced them with 10AWG but it doesn’t solve the basic problem, the efficiency will be really low and it will burn easily during starts.

Just to get some figures on it:

Resistance losses at takeoff (80A) is 1200W, at flight (40A) 312W. Ouch.