I’ve been reading quite a bit in this forum. Particular posts about motors. It seems to me that none of the motors that are commonly used by the community are trouble free without modding. Are there no trouble free motors to be had? I need a few motors in the range 2kw to 15kw that are trouble free and can stay in saltwater permanently for a year. Any pointers?

Well, if you’re willing to pay for quality, this would be your option and my best guess for continuous use in saltwater:

Do you want to leave them in the water for a year without ever bringing them above surface?

I don’t think any of the efoil motors would survive that to be honest!

Thanks. And yes, I would be willing to pay for quality.

Yes I would leave them in water for many months or even a year without bringing them above surface. I will use them on boats.

I question this from the point of view that even outboard motors are normally tilted up so that the gearbox and prop are out the water. Why leave them below the water?

If you really want to leave them below water, then you may want to consider and inboard style where only the prop and shaft would sit below the waterline…

I’m trying to avoid inboard style because it complicates the project(s). Amongst other things that requires cooling of the motor.

Then the only real alternative is either running through motors as they will eventually leak, or bringing the motors above the surface. However even in a salt environment these motors may not last long if they are not being rinsed off.

They are very minimal in comparison to the likes of Toqeedo electric motors etc.

Motors will do better permanently submerged than in and out of salt water with poor cleaning. Just have a look at any metal below the low tide line. Usually in good condition.

That’s not true at all! Corrosion will be way faster and deeper if left in salt water. If raise and not washed at most you’ll get some surface corrosion.

That metal is not aluminium! Its very often either 316 Stainless or heavily galvanised.

If you don’t believe me take an untreated bolt and submerge it in salt water and then take it out while leaving another permanently in.

Obviously I will have to use sacrificial anode, but that should take care of it.

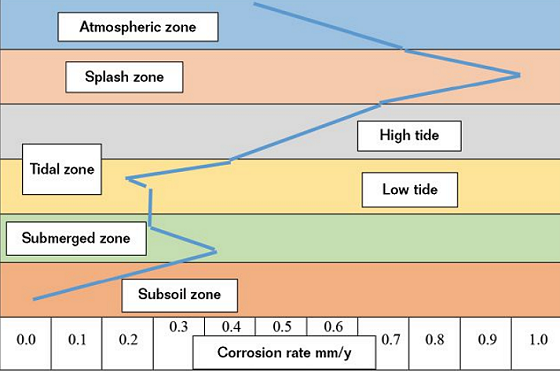

Here’s a diagram for corrosion rates of steel piles on an oil rig platform. Note the increased rate of corrosion in the splash zone, and a decreased rate when submerged.

Corrosion is oxidation. The deeper you go, the less oxygen, so less corrosion.

No, that won’t… You need to consider the degradation of the seals etc. These motors are realistically closer to ip67 rating and will have water ingress if left in the water. Once salt water is inside it’s gonna be goodbye motor. They simply are not designed to stay underwater. If they were, all the major electric motor and thruster companies would be using them, except they not…

Thats the first image that pops up on Google… I hate to break it to you though, we not building a steel oil rig.

You need to look at galvanic corrosion of an outboard below the waterline! Galvanic corrosion happens far faster with an electrolyte present (salt water) than in the air.

Strongarm is right about the corrosion. A saltwater battery with carbon, saltwater and aluminium is called an aluminium air battery because the air (oxygen) is key to producing the current. This is also what causes the oxydation (corrosion). It works well in saltwater, but much better in air simply because there is more easy accessible oxygen in air.

I’m worried about what you say about the seals though. What are they made of?

Corosion is only one part of the problem. Marine growth will be the killer in this environment. You can apply ati-fouling, but it will not last a year. Your propellor will end up with growth. Barnacles will worm their way past seals, the whole thing will foul.

Boats designed to be permanently in the water use bronze fittings as the copper inhibits growth - but even these don’t last a year without having to be pulled out as water blasted.

I assume you are thinking about autonomous craft. All of the successful long distance autonomous craft have used inboard motors with magnetic couplings so that there are no hull penetrations. I have see one that used a greased shaft with positive pressure continuously replacing the grease as it leaked out.

Either way, no motor you have seen on these forums would be suitable.