ABS might work, best material I used to print props so far is eSun PLA+ (the plus is important). This stuff is really strong, if sanded it gets also very smooth. Use 100, 200, 400, 800, 1200 grit. Only con is the relatively low melting point, better not leave it in the car parked in the sun (in summer).

ABS is good stuff. Brush it with some acetone, and you get nice smooth surfaces

The mount printed correctly, very clean, seems strong with good layer adhesion, happy about that after 24 hours of printing. Used this stuff before for drone gopro mount, took some 150kph hits fine.

Mounted New prop and tested the mount, fits like a glove and IS tight without shims.

Will it hold?

The cable guide is printing now. I will hold it with velcro to the mast.

48 cm rear wing will be there by the weekend.

I printed 3 sets of props just to be safe

One Set was sanded, one Set was cut down (to gain rpm and reduce phase amps) one Set with improved print parameters IS raw from printing.

Very cool Adam!

With TPU it should be the strongest, but how is it to get on/off? Will not slide by chance?

Mast mount survived.

No vibrations, I feel my printed props and tpu mount were giving less vibrations than before.

The mount is just slid on, and has enouth friction to stay in place.

Here is how it looks with the cable guide. I had to tape it, I feel like the tape did a good difference.

I checked the rpm, loaded rpm is only 1400 or so.

So I tried to cut down the prop. With the prop small like this, I had 2400 rpm, but not enouth torque to start.

No load is 4100 rpm, so really in the Bad efficiency range with very high phase amps, and controller overheates. The vesc is set to 100A phase, I feel like more will only make things worse ?!

I managed some good runs 200m or so on foil, reduced the throttle, but overheating stops me after a while.

Some pics, I left my phone running but with the sun and the field of view, did not capture the best runs!

I installed my stab upside down to test, it worked better AT low speed but not at higher speeds.

When shimmed about 2 degres and upside down, I had the best results and had better position on the board, not as much forward like last tests.

Anyway, a good test on the water, nothing broke exepted one of the cutted off blades, zero water in box after 2 hours of testing.

Hello Bzhwindtalker .

Is it possible to share the STL files for the motor mount and cable guide .

It is very interesting design.

Thanks.

I posted them here

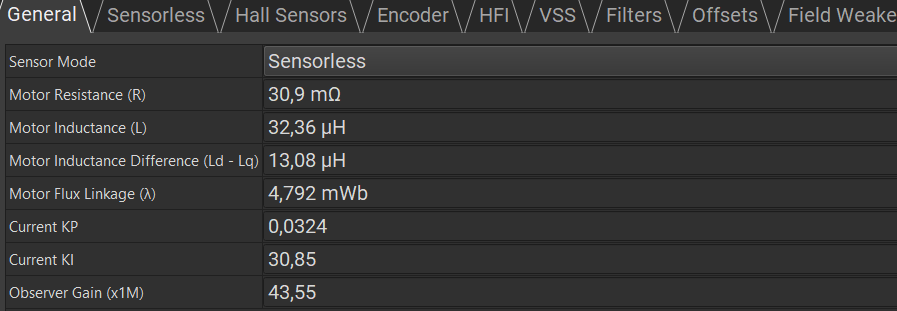

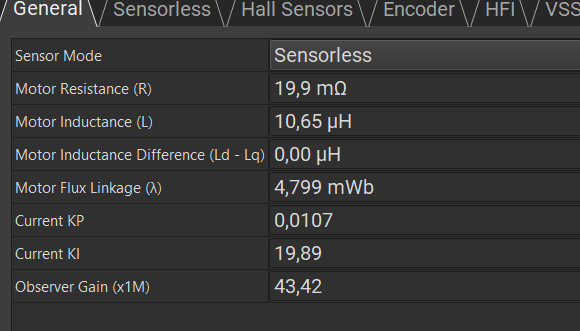

Updated the VESC and run motor identify again. The parameters are quite different. I also had performed auto identify on a power supply and not a battery.

Will try if it makes a difference

Before

After

First of its kind on the forum. Kudos. A new step towards the perfect tool-free DiY FDA assembly.

Has the mount moved during use since ?

The mount survived another session just fine.

I re-cut the prop, until I reached 1900 rpm. It was slightly better, I could downwind for a while with reduced power and some pumping, but impossible to foil for long upwind.

New vesc settings did not help unfortunately. I think I had another 6374 somewhere I will see if I can use that and try instead of the maytech.

Here is the recut prop

Received my 48cm rear wing.

Will test on sunday

48 cm rear wing gave much better results, with full battery I could e-foil for some minutes before overheating.

I checked the other 6374 I had, but it is only 48mm stator. Also the windings were damaged, so it would need a rewind, not worth it.

Next step is either 6384 or 200A vesc

Edit, ordered a 6384 -120kv from Ali at 67€

I think the maytech motor is already at saturation and this is why the RPM are so low. Pushing more phase amps would not really help then.

Yes, I had checked this option. But it is 107 € when I look at it

89€, try from a private window.

@SoEFoil private window - yes - you can see the minimal price, but they write that it includes a welcome gift

@Bzhwindtalker how is it possible that price difference?? I am in Israel, for example the 6384 motor including shipping $53.5.

Maybe they calculate some taxes for you?

Yes probably the 20% VAT being calculated. It is now mandatory for all eu sales.

Adam

Built a second battery, from cut down 14s4p ebike battery resurrected from deep discharge due to bms malfunction. I charge them at 0.5A in a secure environnement, UP to 3.5v per cell, then let them site for some days. After, I check the cell voltages.

Those battery are unfit for anything serious, when they get recharged from 0.5v per cell, one or two Banks per pack can go Bad with self discharge. But as I only need 8 out of 14 groups, I could recover 3 packs already for this efoil project.

I have some bms to install, but for some reason, they Can only read 5 cells when configured in 8s They are supposed to be 6-15cell compatible. Those bms have a led bar with on/off Button and error codes, plus bluetooth.