You’re a bit further to the front of the board than i’m used to seeing, does the stab/wing combination match well?

It is better with the 48 cm stab. I already have a 5 degree shim under the foil.

I feel like something is not right with this board, so efficiency is not great. I should have back feet over the mast, as it is with the fanatic dw I modded.

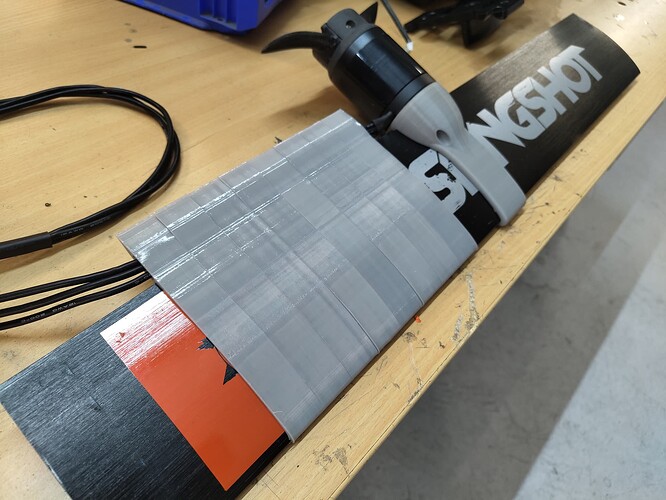

Testing something out of tpu for the cables.

Hope I can solve this ongoing topic and get peak efficiency !

First test was a fail, I extruded the profile the wrong way.

Second test seems interesting.

The mt60 barely fits the hole with the tpu, but overall it should work.

Maybe longer to install than tape ![]()

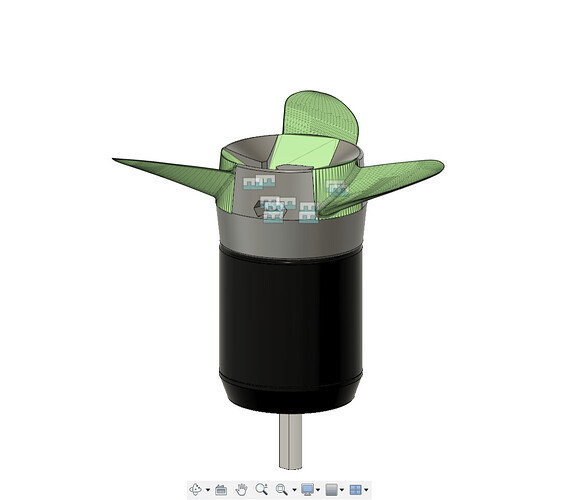

After Many hours of unmonitored printing by 25mm sections

Processing: IMG_20240122_155854965.jpg…

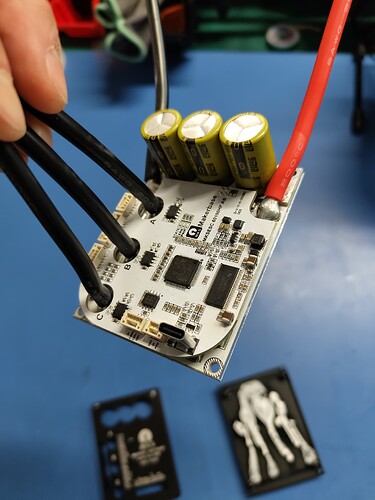

Also received the 60100 vesc, seems like a good thermal design, much

Better than maytech. Bigger cables 8awg vs 12 awg on the maytech

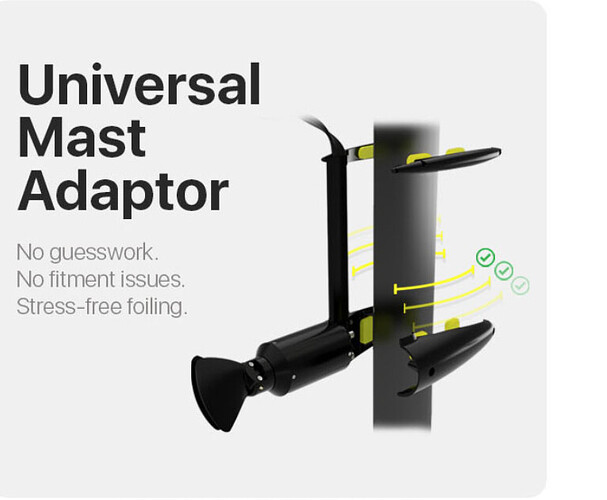

Did you ever consider trying something like @Mantafoils has done for their Takeoff assist? They have the motor cables separated in a “trailing mast.” Might be easier than sliding all the 25mm sections down the mast.

I take the servo cable from the 75200 and connect it to the 60100 - nothing works, but for some reason the relay on the Maytech receiver clicks. This is because they changed the pinout to a mirror one. When asked for what purpose, Makerbase support answered, these controllers were developed by different teams.

I agree that this controller is more powerful than the Maytech. But Makerbase and reliability are completely different things. I have burned out 4 controllers and three of them for no apparent reason.

Have 2 75200 and this 60100 to test out here. The 75200 will be evaluated for another application and will be pushed to the max. The 60100 is for my foil, maybe we also put it on the test bench torture.

I wonder wich is best for hydro, I would suspect this approach is not as good as one contiunous profile, but I could be wrong as I added cross section. It must be pretty rigid to prevent flutter/vibrations.

I imagine your continuous sections would produce a bit less drag (though the leading edge of a printed part may not be as smooth as the mast itself).

In another thread Mantafoil stated the sections are aluminum

And the 3 phase wire seems… flat to decrease this small mast section thicknesss…

The New guide works perfect ! Now the board is more balanced and no more cavitation.

I could go 45+ minutes on one 7s4p battery

Removal is quite easy in the end.

I think the stance difference between both boards was due to the taping and motor height.

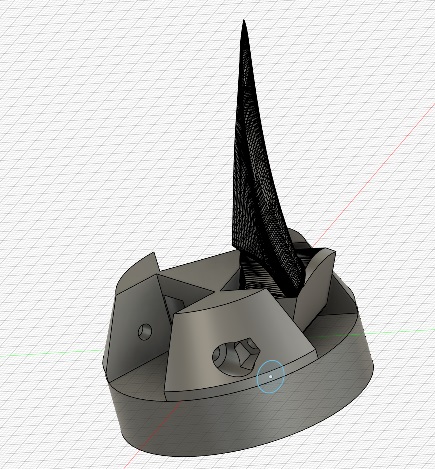

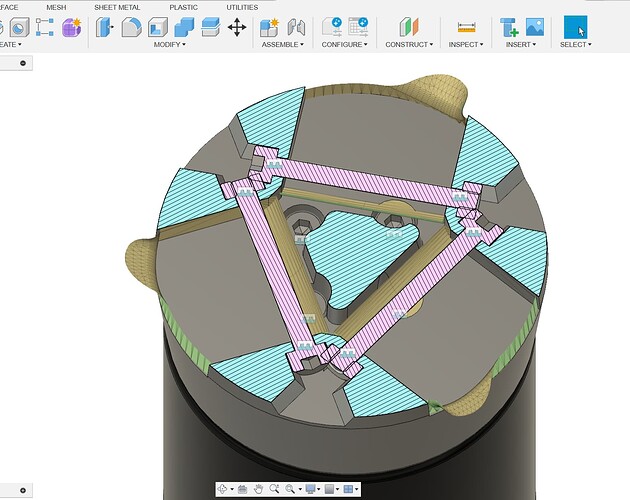

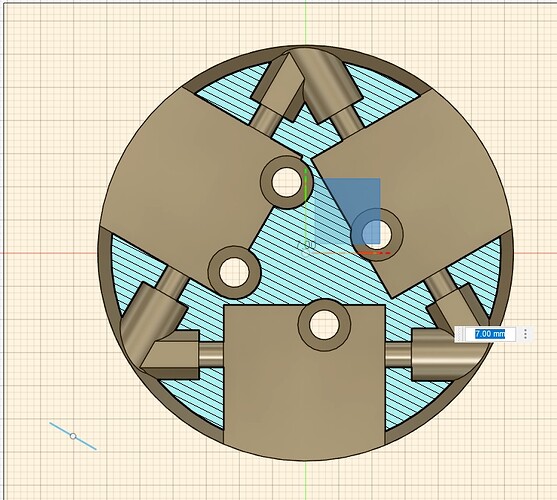

If it helps, the genuine 3 blade hub from foil drive only has 3 holes for mounting the hub to the motor housing. One of the 4 on the motor is unused.

Thanks for the information, the issue is mainly for the 3 bolts holding the blades in.

They are interfering with each other due to the blades Root width. With stl only, any modification to the blades is tedious !

LOOKS GOOD.

Did you also model the blades to make the root thinner?

files available for your design?

Unfortunately, my level is not high enough to model the blades. I used stl from Volker propeller. If you need files, I can send them.