Hmm, mine is oposite i used fiberglass on board and carbon for hatch.

I dont have problems with signal penetration eaven with whole board submerged few cm under water.

Best would be to put external antena in nose of the board if you can.

If you think cad modeling is issue wait unthill you get to sanding and filling😆.

But i hope you will not have to sand so much as you will use vacume bagging.

What signal do you use for remote? I use 2.4 inside my Flipsky VX3.

Br

Yes it is also 2.4Ghz wifi.

Great idea😁but have to finish my buld first😅

How is your snap connector doing after 3 months ? Still waterproof ?

Still waiting to be used in a build

Update on my realy slow bulid ![]()

Somewhere along the way I decided to go with inflatable → ordered one from Alibaba.

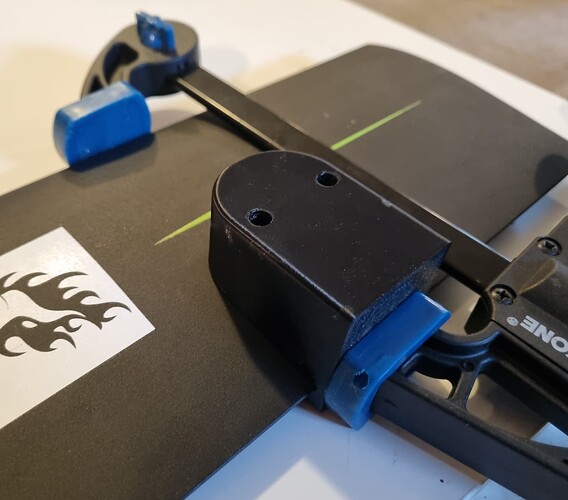

→ 3d printed the enclosure:

It remains to be wrapped in fiberglass…

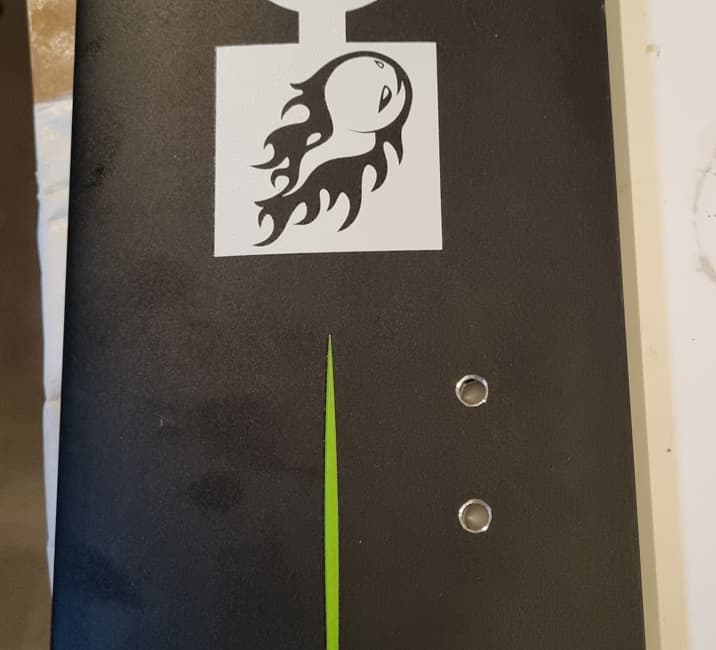

As you can see on the video hatch will have no hinges, at least not the classical ones.

Idea is not mine, I believe I saw it on one of the major brands.

I have also decided to go with Flipsky 6384 motor.

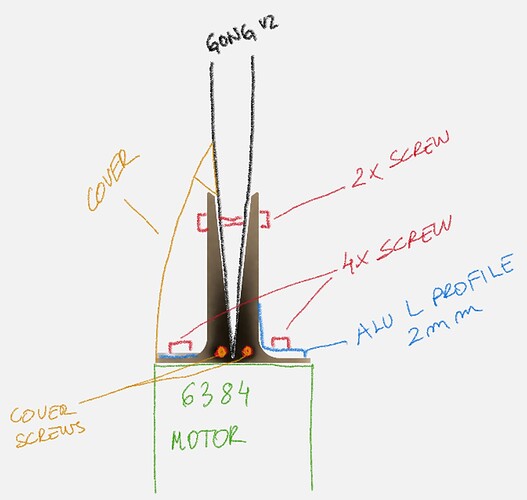

→ 3d printed mount for Gong mast v2:

→ also 3d printed adapter for Flite prop:

Hi, I really like the adapter for the Flite propeller.

Can you share the files for him and for the motor mount?

Thanks in advance.

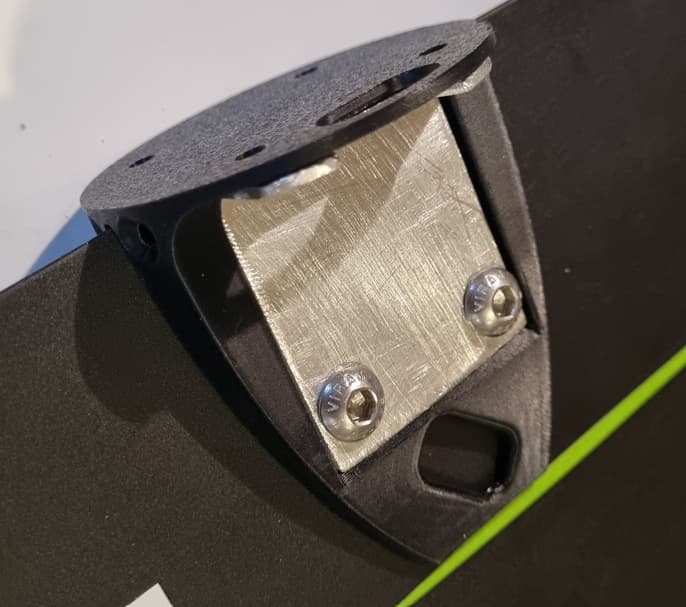

I will second @iasen_vak, this is a nice motor mount design! It seems quite robust with the aluminum brackets securing the motor in place. Have you made those yet? I imagine not too difficult to cut and bend in a home workshop. Hopefully you can share the files.

Thanks…will share next week…

If anyone needs files please PM me.

Aluminum brackets are constructed from an aluminum L profile:

Firstly, I trimmed them to shape using angle grinder so that they would fit the 3D-printed mount:

Then I drill holes using a 3D printed template:

Additionally, drill holes in the mast using a 3D printed template:

Screw everything together, and I have what appears to be a pretty robust mount. Only time will tell ![]()