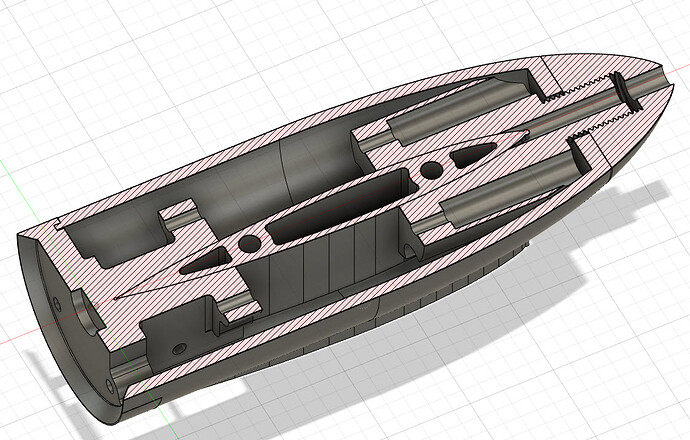

In the case somebody need it: Cabrinha mast clamp for APS63100 motor. PLA printed with 20% infill, front and back clamps filled with epoxy.

Thanks for sharing. I am starting into initial steps for a diy project, currently in the “WTF I am so confused” stage.  I will be needing to figure out how to attach a 6374 motor to a gofoil and axis mast. Assuming I can’t find exact matches, I figure a short term solution may be to use something like your Cabrinha perfect fit, then modify to get the fit at least partway there…even if it means filing it out or adding shims to make it work. I know, caveman stuff compared to the best-in-show stuff you’re all doing … but it’s better than the duct tape, bailing wire, and zap straps that is my default plan. <which is funny because it’s true>

I will be needing to figure out how to attach a 6374 motor to a gofoil and axis mast. Assuming I can’t find exact matches, I figure a short term solution may be to use something like your Cabrinha perfect fit, then modify to get the fit at least partway there…even if it means filing it out or adding shims to make it work. I know, caveman stuff compared to the best-in-show stuff you’re all doing … but it’s better than the duct tape, bailing wire, and zap straps that is my default plan. <which is funny because it’s true>

So…now need to find someone with a 3D printer

How did you seal that APS63100 ? no problems with the bearings in salt water?

You can’t seal it, it needs to run wet for cooling. Rince it with fresh water after use. Replace the bearings with stainless.

As @sat_be said just stainless steel bearings. In my case even easier, I run on lakes. Tried to use original bearings but they stuck after first use.

awesome @Seaman, I plan to run mine also on lakes ! I’m looking to adapt this to use with a Flip Sky 65161 120kv motor on an AFS mast. Would you share the STEP or 3D file ?

Here you are:

.f3d Cabrinha mast clamp for 63100 v2.f3d - Google Drive

.step Cabrinha mast clamp for 63100 v2.step - Google Drive

thanks a lot mate ! you’re a star. how big was the tubing that you used ?

I did not use tubing in the mast. Just drilled 5 mm hole through nose intake to the front channel and used it as a tube. Then drilled base plate above front channel and sealed it with a silicone gasket.