Hi, yes I still have some available. Send me a PM to sort it

Hi guys,

I have 2 motors ready to ship without prop & duct. 650usd each. DM if interested.

Cheers

Jake

Hi Jake,

Do you have any of these motors left for sale.

Is there a folding prop on market that will fit these?

Kinda reviving this thread, but I got one Jake’s motors a while ago. I love it, and it works great!

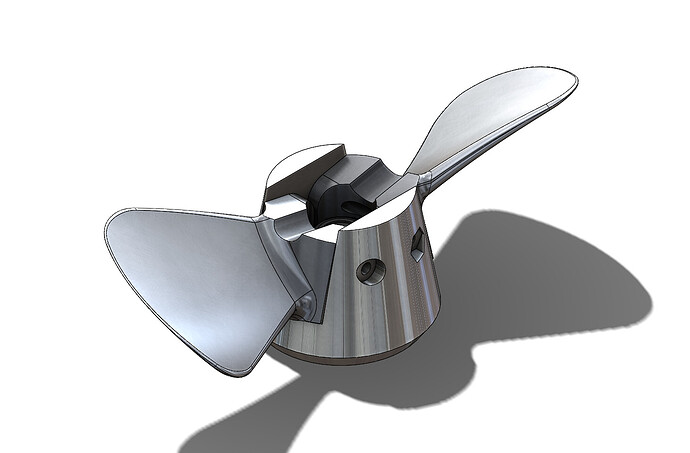

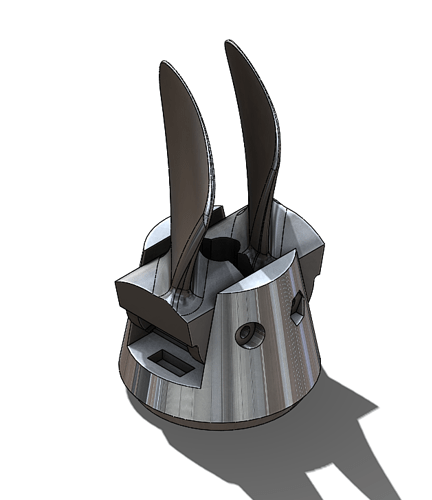

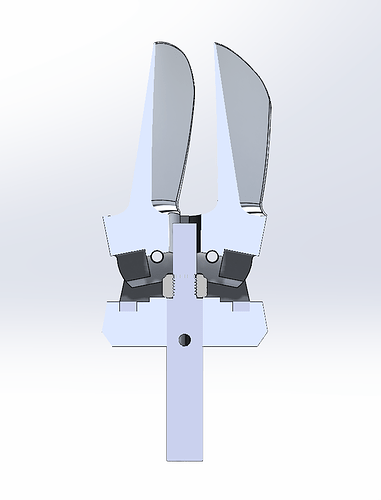

As far as I know, there is not a folding prop commercially available that fits Jake’s design. Maybe one can be modified to work, but I have been working on making my own design that can be 3d printed. I am finally getting some good results. I have a working design that has been able to hold up a couple of rides now. I am in the process of optimizing it.

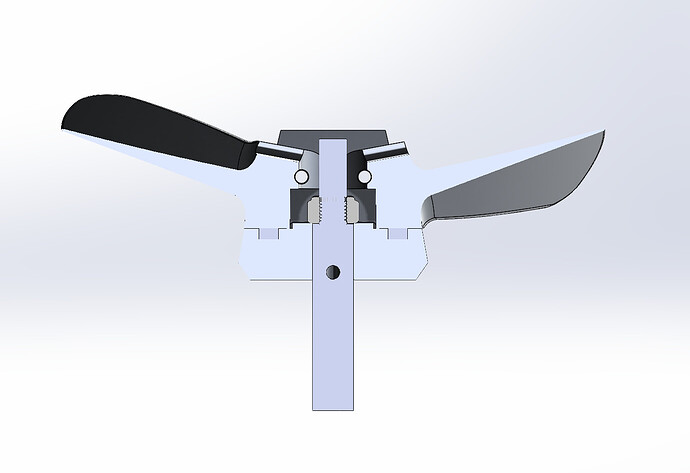

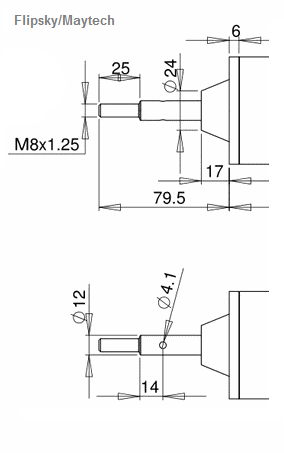

Do you think you could adapt this Jake motor dedicated prop design to a 65161 motor with threaded shaft ? ?

Probably, but I would need the technical drawing or the model of the shaft. Do props thread onto the shaft of the 65161 motor directly, or does a nut hold them on like Jake’s?

This prop has the hub and blades designed for clearance for a nylock nut to hold the propeller on the shaft.

Here it is. People use a nylock nut to hold the propeller on the shaft.

I am going to do a little more testing on my setup and then I will try to adapt it to other motors! Keep you guys updated.

So… I tested the prop shown in the images in my post above today. It went well; however, I made a mistake when printing it. I forgot to print with 4 perimeters and instead printed with 2. This resulted in the blades breaking under some hard riding. I “think” if I had printed it right, It would have survived just fine. I did about 7-8 take offs on it without it breaking today with the 2 perimeter print. My previous design with slightly less surface area on the blades survived 4 trips with no issues with 4 perimeters.

I still think I have some tweaking to do. I believe that motors that have more power than mine will probably break this version of the prop. That being said I believe I was able to adapt it to the 65161 motor. Thankfully it was pretty similar to Jake’s design and didn’t require many changes.

The STLs can be found here : Flipsky 65161 motor folding prop - Google Drive

For printing:

- I print the props with PETG Carbon X filament on my prusa MK3s

- Hub is printed solid right side up without supports at .2mm layer height.

- blades are printed horizontally so that the layers go along the length of the blade. They will need supports. I was able to print them with minimal support just under the center part where it connects to the hub and the start of the blade. It will depend on your printer. Print blades at .2mm layer height, 50% minimum infill, triangular infill, and 4 perimeters. Probably good to print a little hotter than normal too to get good layer adhesion.

- There is a file in the folder called hub stoppers. Those need to be printed in TPU. They reduce the shock of the blades opening.

The design uses 2 #6-32 screws at 1 5/8" long and 2 #6-32 nylock nuts.

If something doesn’t fit right, or if you think some changes should be made, let me know. This is my first time designing a prop, and I definitely think it will need some more tuning.

Also for reference me + board is about 105 kilos. I hit about 35 km/h today on my ride with this prop. So definitely not the fastest. Also it is not as efficient as the aluminum blade prop that Jake designed.

Would you have a picture of Jake’s propeller ?

Not at the moment. It is the one detailed above in Jake’s very first post. You can see the prop in a couple of the pictures kind of. I assume a lot of the inefficiencies of my folding prop come from the surface finishes and thickness of the blades (have to make them pretty beefy at the base to hold up when printed).

I am using one of Jake’s motors on a Tow Boogie build and the shaft is spinning but the propeller isn’t. Do I just tighten the nut at the end of the shaft? If so, is there a trick to keeping the shaft from spinning while you twist the nut?

Shear pin? 20 Char 20 Char

I have some motors to go, PM me if interested.

@Twstahle good to see a folding prop being tried out!

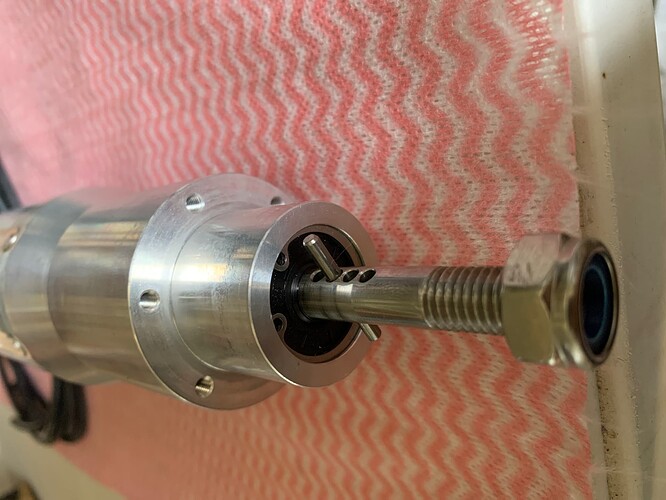

@hivebrain as @sat_be mentioned, you must have left the split pin out of the shaft, remove the prop and install the pin in the 2nd hole out from the end of the motor…

I got three motors from Jake, I used one on a Foil Drive sort of setup with the motor a few inches under the board so I can cut the motor and chase bumps once I’m up and flying. The motors have way too much power for that, but it’s fun at 1/8 throttle. I’m using the aluminum three blade props that Jake provided. I’ve tried printing props with CF in polycarbonate with smaller motors, and they work, but don’t survive long. the other motor is for a tow boogie, but the project is a bit stalled. I got the electronics working for a “follow me” system and the first iteration of a hull going, but life has intervened. I’m having too much fun wingfoiling and doing long distance dirt bike rides.

I also got a little wrapped around the axle restoring a couple of vintage adventure bikes and 3D printing Faux Drives. ADHD running wild:

Hi Jake, i realise this post is now quite old. Out of interest do you have any motors for sale? I’m in Australia, starting out constructing an efoil. Let me know. thanks