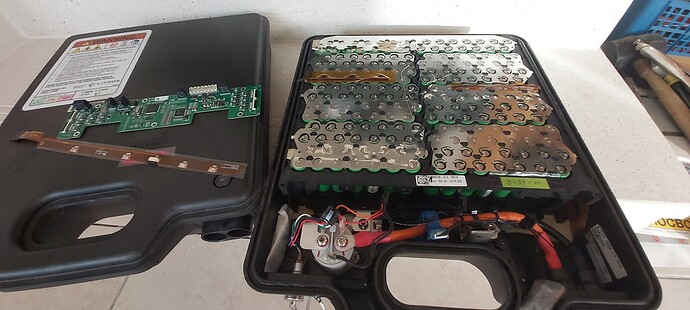

I just recently opened a second one, with better success. The first one I wasn’t persistent enough around the handle and I broke the lid.On the first one the glue that is on top the cells to secure the temp sensors was also stuck to the lid and as I pealed back the lid it pulled off the soldered battery contacts in those places, not ideal. A little heat in those spots will help loosen the glue.This one I managed to open with a metal 3 in one tool and a hammer along the seam, the handle part was the hardest but I got it off intact without damaging anything. I then had the BMS from the first one which was a new battery that got damaged in shipping and swapped it in the second one that I successfully opened and it fixed it. The second battery one day stopped lighting up and charging. Charger displayed a E209 fault(Lift said that means the charger didn’t detect a battery). This fault occurred after the Lift Efoil was used untill the low battery came up on the remote and then not charged for a few days, long story short somehow the BMS stopped working. Same thing happened to someone I know who stored their battery at 25% for a couple weeks, can’t say that the two experiences are related, but seems to me that the BMS inside the battery gets damaged if the pack voltage gets too low.

Good job! Looks like they have a Kilovac there, can you see wat specs it has?

I already glued it back up. I don’t have that info unfortunately

Thanks. Looks like this model : https://www.te.com/usa-en/product-2203194-1.html Rated for surprisingly low amp but the rating is maybe conservative?

Nice work! What method did you use to split those cases?

Just used a 3 in one multi tool/scraper and a small hammer. They are visible in the first pic

Really interesting to see inside !

Are the 2 platic parts glued together with some kind of Sikaflex / glue ?

I still have my Onean battery to cut open guys ! Hopefully I am back to it this weekend and can share this journey. Also I need to reply to the other post as well

So each cell is individually fused, looking at the nickel plate, right?

Dear Slacks, there are such battery packs I also have to repair the bms fall does not work, how to get them? The factory doesn’t answer anything for me. Honorable for your advice and help. I attach a picture of the work and am happy to exchange information. Thanks Ripacs!

[quote=“Ripacs, post:133, topic:10490, full:true”]

Great battery pack ! Can you measure the thickness of the plastic on the cover ?

Thank you !

I highly doubt they would answer an individual customer. Those packs are not meant to be repaired, imagine you « fix » it and then one day it catches fire. People will think this is a brand new Lift battery catching fire, and Lift would get serious shit to deal with !

That said, for us diyers, I don’t know if we can purchase those bms being individuals.

Hi Thom, yes 3mm thick.

Hi Sliman,

I understand, and in theory I am right. But something is wrong with BMSs. They do their thing and ban it, but even if there is no longer a problem. The fuse is slower than the BMS, so it breaks down in the event of an accidental assembly lock. Rather, people would have a reset function in the software or possibly a button to tell if the error is gone. It was so very expensive for everyone and only a badly connected plug was the temporary problem. Can I buy BMS?

I don’t believe so. I remember them having a single industrial spot weld on each side with a custom cut nickel plate.

Well that’s what he ment by individually fused I think. The way the nickel plate is cut is what I would also call cell fuse design

Yes, correct, looking at the picture the nickel plate is cut in a special shape, and can not find any other explanation than that its a safety feature/ kind of a fuse?