Hi

I would like to share my battery build. I assembled the first version of my eFoil this summer, and I am planning to upgrade it during the winter. I will paint and clearcoat the board, tidy up some electrical stuff etc, but the battery will mostly remain in it’s current form since it works flawlessly. I might add an external charge port in the future…

Anyway, at this point I can share the pretty much finished battery. My board is space constrained, so I went with a Pelican 1085 case. I calculated that a 14S7P battery will fit nicely inside, and with about 18-22A current consumption during foiling, my cells should see less than 5A each. This calls for high energy, medium discharge cells to optimize run time. LG released their M50LT cells recently, so I selected those for the job. Their maximum current output is 14.4A. That’s easily enough to support the 65-75 battery amps I usually use to take off (about 10A per cell). I am 65kg. The cells don’t warm up much, but if you are a heavier rider, go with a high performance cell. I observed max 34c, logged with LTT BMS. The run time is about 1-1.5 hours.

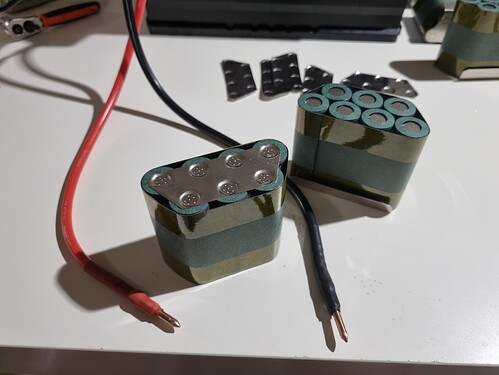

Starting off with the cells

I hot glued the cells into packs of 7

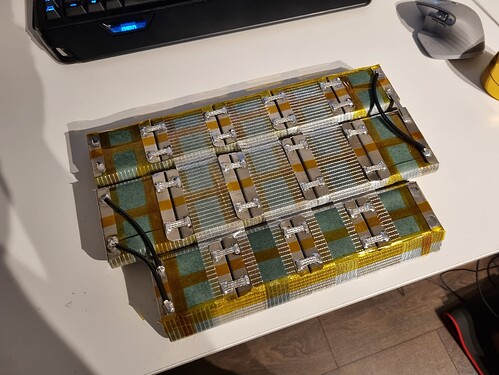

Found myself some 50 mm and 30 mm wide nickel. The 50 mm wasn’t annealed, so I had to use some annealed 30 mm wide that I had bought earlier. Annealing makes the nickel softer, so I can form dimples for the LG M50LT positive ends. LG decided to recess the cell tops in this model. Most other cells don’t require dimples.

Cutting the 50 mm wide nickel with 3D printed guides. These were for the negative ends.

Forming dimples with 3D printed guides. I only did it for the positive cell ends.The negative cell ends are flat.

Spot welding. The first 30 mm piece is visible here. I welded another one to the cells as well, offset so I can later bend it on top of the flat cells. See pic below.

Bent the tabs on top of the cells and started constructing the pack with fiber reinforced tape

Series connections completed

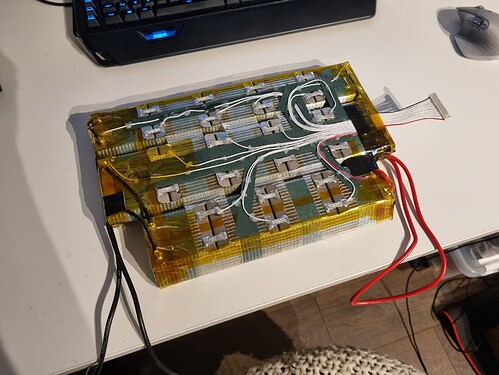

Balance leads added

Shrink wrapped

Added BMS and glued the pack to the case with structural adhesive

Pack completed!

The Amphenol surlok connectors fit, but barely. I had to cut 2 out of the 4 mounting ears off.

Added battery strap rails to the board

Battery strapped in

That’s it! I hope that someone finds this useful