75200 is a usually a good choice. I had one just randomly fail to start on it’s 3rd time out, but I have two others that have worked flawlessly.

The flipsky 75200 pro is nice because it includes bluetooth built in. This allows it to connect to the vesc app on a phone and you don’t need to plug in a separate bluetooth receiver if you ever want one.

There are water cooled options but it can also be cooled passively if you place it in contact with a heat sync. This is the approach used now in most commercial efoils and with the adapter-plate fliteboard based builds mentioned above. The ESC is mounted to the top of the mast and cooled by contact with the mast plate.

I have this foil from Neil Pryde. Front foil = 1602.2 cm2

If its not usable, ill go for the Gong V3 @523 euro.

anyone have any idee how hot a esc get by intesive (ab-)use in efoil boards? i have a water cooled to make sure it dont get to hot … not much more work concidering you have to do all the motor wiring too. but maybe next setup when building a box inside the board…

I use a passive heatsink at the bottom of the board. With a good quality (v)esc (good thermal transfer from FETs to heatsink) and good heat transfer pad it does not get very hot. My TeamTriforceUK vesc A200sv4.1 reports max 45 degrees.

reading lots of stories here about frying esc 's ![]() but anno 2019… so maybe now this issue is better under control ? … but decissons

but anno 2019… so maybe now this issue is better under control ? … but decissons

for nxt year build

Maybe best to post this in your own build topic so we don’t hijack @Slandersen topic anymore.

Personally I wouldn’t use the Neil Pryde foe a few reasons.

- it has a Tuttle box mount so might be more challenging to get a rigid connection to board, Can’t make position adjustments with Tuttle box like you can with twin track.

- I don’t recall anyone having a 3d motor mount clamp for that mast

- I don’t think anyone else has tried it so you could fo a lot of work to find out that it doesn’t perform well

I’m not sure if anyone has a stl for the Gong V3 mast yet so you may want to research that now. Lots of people have used their V2 85cm aluminum mast successfully. Aluminum is less $ than CF mast and has good heat conduction so is proven effective as part of heat sink. Gong has a massive range of foils shapes and sizes so is a popular choice - lots of used foils as well so you might get something for less $ if you luck out. What foil are you considering?

You’re right about the Tuttle box. I can buy a conversion kit, but that’s about one-third the price of a new foil.

I have a 3D printer and the software to design and print the mounting clamp, so that’s not an issue.

The reason I looked at the V3 was that I didn’t know they still sold the V2. Since I’ve found out they do, I’ll probably go with a Foil X-Over V2 – Alu 85. I’m just not sure what size I should choose. I weigh 70 kg.

Small or medium for sure.

i have the curve medium (weight 84kg) great thing (and also fluid xl , beginner foil)

I wasn’t trying to talk you out of V3 - just that I’m not sure if anyone has a stl with the new mast profile. Since you have cad skill you could likely make one or mod an existing one, several great approaches to motor mount here for inspiration

Yes V2 components are still available but not the full product line , Gong is migrating to V3 as it’s their current generation.

I started with V2 XOver and have L XL and XXL sizes with the 48cm stab. I ride the L size mostly and I’m 85kg. The stab and fuse length are important as well

Problem with Gong is they almost have too many choices - analysis - paralysis sets in ![]()

You might want to determine what prop diameter you want to use as that will determine motor clamp above fuse distance, wire holes in mast etc😀

Here you go: a .step file for the Gong V3 (17 mm).

Use it at your own risk ![]()

My 2ct worth:

-

The Flipsky watersport kit is nice, but the propeller is FAR too big: I used it at the beginning and found it VERY hard to control, and only later realized that the massive blades are an issue when you go off the power, because they immediately turn into resistance and you nosedive into the water. I used 3D-printed props, which are fine until you breach at full power and they can spin off their blades.

But I ended with the one from Flite ( Discussion: Fliteboard prop for Flipsky 65161 ) It is the best option, if you can ream out the hole from

10.95 → to 12mm I used a stand-drill and it went smoothly - perfect balance!

When I snap my finger against a 3D prop I hear a “clack” sound - with the Flite it is a crisp “ping” sound: The injection plastic is tougher, harder and smoother, and the cost is almost the same as a 3D printed, ordered one. -

I used the 75200 pro V2 , because it has Bluetooth and comes with the button that turns off the complete unit: No sparks no battery drainage.

The bluetooth is handy when you want to tweak the setting while sitting on the dock and not at your laptop. -

I chose to put everything (Batteries, Controller) in a waterproof Photo-Suitcase from Amazon (LYcus HC-3310 ) and was impressed that it is 100% watertight even submerged. Very easy to build

-

The box allows me the flexibity to use my setup in 2 ways and the change only takes 15min:

A) As an efoil, I used a simple tie-down strap to attach the box to the end of the board: I can stand comfortable with my rear-foot touching the box, which gives me the perfect position for balancing over my foil.

B) or: I move the mast over to an old surfboard from the dump that I have cut in half: → tow-boogie -

Ever since I tried it as a tow-boogie I don’t want to go back to the efoil: I can use my favorite wingfoil board with whatever foil I choose and when the wind dies, I get the boogie out and continue my session with the “electric wind”.

The board is lighter and more responsive and there is no resistance from the motor on the mast of my foil. -

Watercooling is not really necessary: The ProV2 only comes as an aircooled controller. I used that directly in the box without cooling and could go on efoil for about 30min before it reached 70C in Summer (shown ‘live’ in remote so you know when to pause). In winter I could go longer. As a Tow-Boogie it got hotter (15min max) So I have glued a larger aluminum plate on the outside of the box and removed the plastic to mount the controller directly to that plate. Even when just aircooled it was very usable. Now I have the box sitting in a bit of water and the temps never exceed 32C.

I made that choice because I didn’t want to guide water with tubes into my box: I saw the risk of that leaking as higher than my glue method (Camping-van Roof-Window sealant: Flexible and bulletproof: I used 8 screws to squeeze both sides together and sealant is also OVER all screwholes on both sides.)

Good luck with your build!

You likely know this but I will mention it anyway. You can put your phone in a waterproof case and use Vesctools on the phone to create a log file of the session.

Nice write up overall ![]()

I’d love to see pictures of your dry box with the glued-on plate. I also have the 75200 pro and am weighing my options for cooling (if needed, as you mentioned)

Hi Tolson,

My build is really nothing special and I did not put much time into it.

Sorry the inside of the box looks quite “messy” - it was never meant to be seen by anyone but me ![]()

There is a 10S Battery block on the left and right (=20S ~72V Nominal)

Here I used the smaller 75100, because the 75200 stopped working ![]()

In the picture below this one you will see the flat plate counterpart on the outside.

These strips on the inside basically just ensure that the pressure is kept evenly on the elastic compound in the “sandwich”. I thought about just glueing it on the plastic, but it felt “flimsy” and I have seen thermal expansion cause separation of my rooftop campervan window. Also the plastic bottom might flex and crack apart from the rigid aluminum when dropped. The way it is now nothing will tear it off…

And here the outside:

I could have put blobs of that glue stuff on each screw on the inside and outside but ran out of goop and I had already pushed it into every hole before putting the screws in: I am not worried.

Here is the box on the board during my first protoype-test:

Now the board is re-worked: It has a “bay” in the center where the box sits on the bottom, right at the waterline. Usually I just splash 5cm of water in that “tub” and the water never gets warmer than ~30. Sometimes waves fill it to the top, so I can attest that he box stays watertight for longer durations.

Hope that helps?

Cheers,

Ulli

Thanks so much for sharing. I was thinking of doing the same with my box, so it’s great to see it works well. I’m wondering, what connectors you used through the box? Are the jackets over the connectors on the outside waterproof? I currently have a cable gland into the box, but not being able to detach from the motor is super cumbersome for transporting. I’m also curious what sealant you prefer. Or will any RV roof/window sealant do?

It’s one of these 90 Degree connectors from Aliexpress:

https://www.aliexpress.com/item/1005008318724037.html

My seller from 1 year ago has already vanished in typical Aliexpress fashion.

Just searching for “Waterproof connector” will not find these (at least for me)

Try “IP68 High Current”: once you find one, it will show many similar products at the bottom. I put the picture below so readers can still see what it was later on.

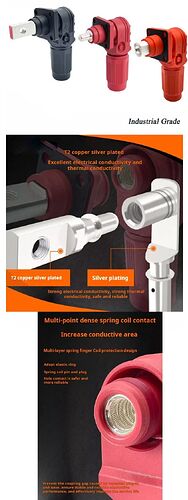

The text says “Industrial Grade” and they are really well made!

You can see the coil inside that grabs the metal on the other side and makes very good contact. They come apart after pressing the button. My model looks like this one and is a bit awkward: Maybe spend a few bucks more for one with a bigger button!

I chose the 100A model - maybe a bit overkill but the box has hung on those connectors in the water more than once after mishaps and I was happy they are sturdy.

As you can see they are not supercheap (~17 Euro/Piece) but I found one seller that sold 3 for 34 Euro.

As for the Sealant: best to ask ChatGPT: I sent this query for a friend in Australia:

Ask it for your region if you can’t find those!

Here a picture of the connector:

That’s basically an Amphenol Surlok connector (probably an imitation). I think Fliteboard uses them, and so do a few other commercial efoils.

searching for “surlok connector” should find plenty of examples on AliExpress

Just giving my 2 cents, but I’ve heard negative stories regarding the AliExpress dupes. Amphenol are pricey, but the best.