Has any built and tested the mast here? I built my own carbon mast and underestimated the amount of carbon fiber it needed to take the flex out of it. Even a very small amount of flex made it virtually unrideble until I went back and added more. Curious how this one performs

Let me get back to you, have you had time to change the angle of the mast? I have more than this part to print!

Thank you

Hi philippe, I started to work on it last week but I didn’t have time to finish it (I had to continue working on other stuff). I’ll try to finish it (and upload it) tomorrow morning hopefully.

It’s updated, if you have any problem with the files let me know!

Excellent work, thank you for your speed, good luck for the future

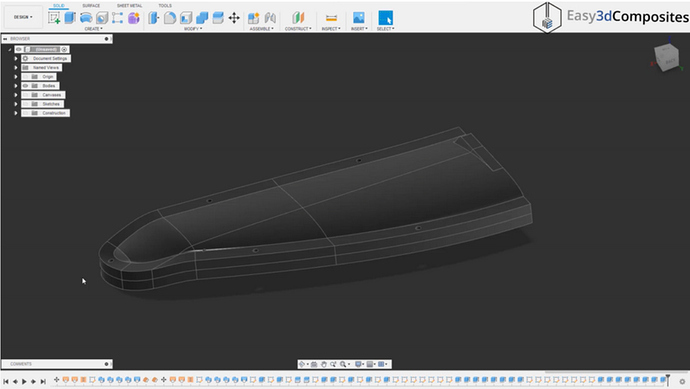

Thanks Philippe! I’m working on adding a course to teach how to design a mold using fusion 360. I downloaded the software yesterday to try it, it’s a little bit limited but it’s free for personal use so I won’t complain haha

The idea is that you will be able to design your own wings, mast, fuselage, etc. and make a mold for these parts using Fusion360.

it’s great, congratulations again, good luck for the future I look forward to the rest

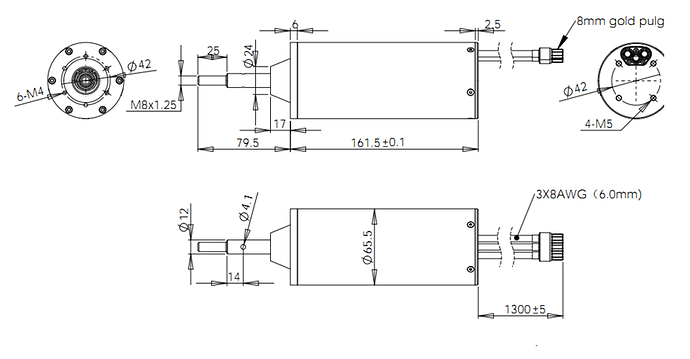

it’s made for a direct drive, the diameter is 70mm. Because the direct drives have different diameters and different ways to fix it to the fuselage, I will make a connector box (to 3d print) for each (with the diameter of the motor)

Hello

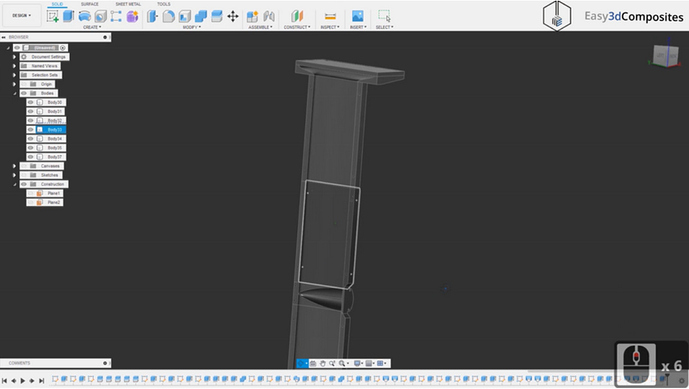

I started to do the FOIL and by examining the rearwing I realized that there was a connection problem, do I need another part to make the connection, photos in attachments, to the thank you

Hi Philippe,

I’ve sent an update to everyone. it’s a mistake, the holes are too far apart. Like I said in the update each build is different so if you think you need to change something to make your foil stronger or more stable feel free.

This 3d printed tool can help to position the holes more accurately but if you want to position the holes another way it’s fine. You can also use fusion360 to change the position of the holes (or add more holes) on this part.

I’m not sure what happened with the large gap on the second picture, you should not have this problem.

If you still have this gap send me a message. Nice job making the wing ! Just a little bit of sanding and polishing and it will look great!

thank you for your answer, I understood the gap on my wing, I probably filled too much fiber and by assembling the two parts I distort the profile, I will start an impression again and make it more stable

Hi… could you make a motor mount / fuselage for the Flipsky 65161? I just joined - $12 well spent.

Hi Noahark,

Sorry I’ve been away for a while…

I don’t have the drawings of this motor so it will be hard to make a perfect model. But if you have the dimensions I could give it a try!

It will also depend on how you will build your mast (hollow or not, etc.). And if you want to make this “connection” between the mast and the motor waterproof or not.

Do you know how to use Fusion360 ? (the best solution would be to be able to design it by yourself so you could make changes to the model if needed)

It’s probably the most popular direct drive motor currently. Also it has the same form factor as Maytech and Reacher (all made by same factory). I believe the shaft area is slightly different on each model and there are options.

Yes, I have a team for Fusion and wanted to ask for your drawings in Fusion format if possible. I like the concept, as it tracks well with my current plug / mold / composite manufacturing process. I am happy to modify based on your suggestions.

Flipsky 65161:

https://cdn.shopify.cn/s/files/1/0011/4039/1996/files/12mm_2048x2048.png?v=1586506076thanks! so I’ll post a small tutorial on how you can make one tomorrow I think. So you can change it if you need (The mast wasn’t design on Fusion360)

Hi Noahark, I’ve finished to make the connection box, you can download it here : https://grabcad.com/library/motor_to_fuselage_connection-1

You can adjust the dimensions and make the changes you need. Like I said before to be it’s much easier if it’s not perfectly sealed. I will simply open it after each use to clean it (I will just attach the 2 parts using a connecting screw).

I have combined the E-foil product and the “Beginner” course with a Fusion 360 course to learn how to design your own wing, mast, etc. and make a 3d printable molds (I plan to add more hopefully).

You can check the details here : easy3dcomposites.com

Hi, no more progress ? Maybe new designes ?

Hi. is it still possible to purchase the 3d files ??