That V5 looks sick!!!

You could had:

- Helps to stabilize the rider during takeoff,

- decreases learning curve time,

- indispensable (at least at the beginning) for riders using a low volume board such as kitefoil boards,

- and much more

I’m thinking of using my modified g2tb remote that i have encased in MasterCho Mod and

Waterproofing Electronics to negate the ziplock bag

Con: we live in 2017. Nothing should have wires anymore

Yes forget that wire thing…will not be the future:blush:

hi, i’m working on an e-foil too with one nuance: i need my remote to communicate through water.

i tried 2gHz: no luck, 75MHz : the technology is too old and too big to repackage. i finally landed on custom made 433 MHz.

Instead of using a potentiometer that requires waterproofing, i’m now using linear Hall effect sensors and some magnets… It works great!

Hello

I seem to be well. Can you tell use more about the linear hall effect and magnet! Where have you buy it?

i got them from mouser electronics.

i tried both SS496A1 and SS495A1, the only difference is the strength of the magnetic field needed.

Magnets are from a hobby store.

for the remote i’m using:

Pro Micro 5V/16MHz Arduino Compatible Microcontroller

Hall effect sensor

Seeedstudio 433MHz Low Cost Transmitter

9v battery instead of 5v to improve range.

coil loaded 1/4 monopole antenna home made

Reed switch to turn on-off through the case

3d printed case.

bunch of magnets

For the receiver:

Pro Micro 5V/16MHz Arduino Compatible Microcontroller

Seeedstudio 433MHz Low Cost Receiver

coil loaded 1/4 wave dipole home made (apparently helps with EM interference)

I’ll release all the drawings, program and part list once i start flying !

So you got your hall sensor completely in your waterproof case and just the Magnet touching the water and the magnetic field of it walking through the wall of the case right?

Exactly, and if on top of that you use a reed switch for on / off, you only have 1 seal between the 2 parts of the case to worry about …

Tested some linear hall effect sensor today, with grate results! the sensor is fixed between two magnets which rotates around the sensor. Simple and smart solution:P

I think this setup is grate! You get the leaver action you want, long travel, and very simple to make waterproof. The signal is also very stable and good. I think it is because the magnetic field between two magnets are quite homogenic and not as easily interfered.

the video is a bit dark so I added a crude CAD drawing, to show how the test was conducted. Now I can’t wait to make a new improved remote! It might also be plausible that Lift foils uses this principle?

in the video you can see the setup in action. A bit shaky as I had to hold it with one hand and film with the other

cheers! will post new remote soon.

Nice work Hiorth. Linear hall effect sensors look good.

Are you ready into a arduino or similar micro and sending via bluetooth to another on the board which generates PWM for ESC?

I’m also building my own, I have an idea to build in a launch/learner control function, i.e full squeeze of trigger when starting and micro can control a fixed speed (which we set), this would help with jerky control when trying to learn. Obviously need to know the required speed etc. that is optimum.

Glen

thank you

yes sending via bluetooth and using PWM signal.

measures to prevent gearbox failure.:

testing slow acceleration, the videos show a linear acceleration curve. Pressing the button while holding the throttle in. the motor goes from no speed to full speed, the acceleration and deacceleration can easily be changed. added safety feature the button must be pressed for the throttle to work.

Ended up using a different curve and controller when water testing the other day, the test remote in the video has a wire

you can also use cheap RF modules … very, very cheap (5$ for transmitter and receiver).

one safety function that shouldn’t be overlooked is a failsafe. It has to be implemented in the receiver arduino and shuts down if the remote signal is lost…

on mine i’m just counting time between signal received… to avoid shutting down for small signal lost, it wait 1 second and then put the ESC at neutral.

Cheap is good, but I think bluetooth is “safer” in terms of interferens with other tramsmitter and so on? Due to the bluetooth protocol

From what i read i think it’s also less regulated, 433mhz or 315 have restriction in some countries.

Bluetooth is also less a problem for the antenna side of things…

But if you want to transmit through water, you need to go down in frequency … 2.4ghz get too much attenuated.

Hi guys. Working also on a remote and thought I would share our approach (although we are in early stages and no CAD drawings yet).

Untested so far.

For the remote:

- Adafruit Mini Analog Joystick - 10K Potentiometers (Mini Analog Joystick - 10K Potentiometers : ID 3102 : $19.95 : Adafruit Industries, Unique & fun DIY electronics and kits) it has a waterproof jacket which is nice.

- ESP8266 for coms (that’s 2.4Ghz wifi) I am thing the Feather board which can be battery powered. The ESP can also be configured just like any Arduino that’s nice. It can talk over I2C to other IC’s.

- ADC from TI to read the joystick potentiometer.

For the receiver.

Didn’t get to work on the interface to the ESP yet. Here I have my biggest question mark:

- I got a cheap one via Alibaba 200amp label: ‘Mystery’.

- It has a 3wire interface but I have no idea how I can communicate with this thing?

That’s it quite early stage still waiting from some parts to arrive but will keep you poster as I make progress.

I like the idea of magnet with Hall sensor I think that is a nice workaround to avoid complicated water seals.

you communicate with ESCs the same way as you do with servomotors.

there’s a dedicated arduino library for that called "servo"

you then drive the ESC by sending it an angle. (same as you would for a servomotor)

the 3 wires are: ground and +5v (handy to power the arduino) and the signal wire (usually white) where you send the command.

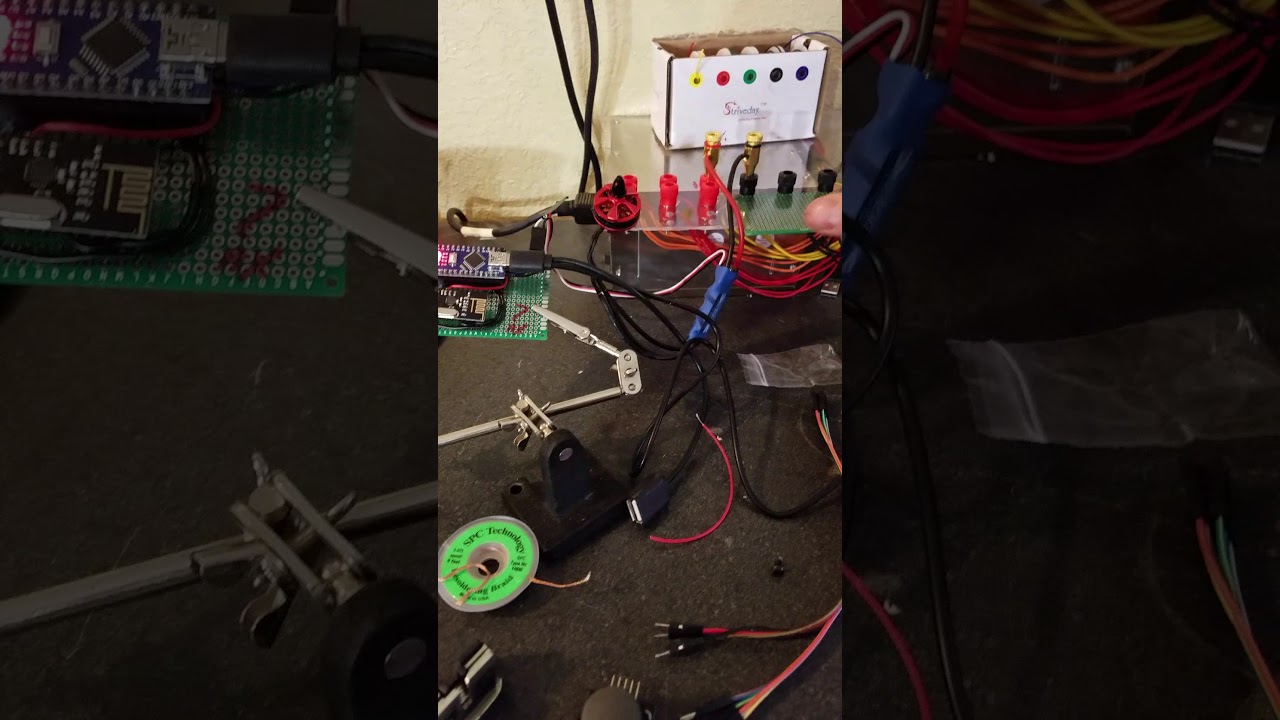

WOW didn’t realize this forum was going to blow up that way. Mat, looks like I’m not the only one with that hall effect sensor idea. It is what Lift did(https://www.liftfoils.com/pages/e-foil-launch). I have a couple on hand right now but buying a few different ones. Im really liking that SS495A. Being high volt input, could allow more resolution. Not sure exactly but cant wait to try it. Im using two Nanos with two nRF24L01. Programmed them for one to be the transmitter and one to be the receiver. Going to be tough to 3d model this unit with a trigger but have some experience with Fusion 360. And a CNC to cut parts. Hoping in the end a good sealing 3d printed model. Here was just the beginning of my project.

WOULD LIKE LINEAR TRIGGER DESIGNS TO PUT INTO THE PROJECT :D. Thank you

I also use the SS495A also tested the A1324/5/6 they work about the same I think. Will make a CAD model soon, I want it to bee 3D printable so everyone( including E-skateboard) can have an awesome cheap remote.

I am using the Arduino “servo.writemicrosecons()” to control the ESC.

Where 1000 equals full reverse 1500 idle and 2000 full throttle/ a bit different for the Seaking… Works like a dream.

No fusion 360 i fast and simple, no problem