g’day

For fliteboarders… FYI. The other day, on my older Fliteboard (v2, 1.5y, ~2500km), the fuselage tail broke, in flight, and drown with the attached stabilizer wing 290 ![]() Only a stub remain in the tube with the bolt in it. This happened right after i changed the shim from 1 to 3, for some guy to learn easier, and went testing it, pushed to 33km/h and baaaam in middle of the bay. Luckily i was near the beach, and not on some of my 30km+ open sea adventures…

Only a stub remain in the tube with the bolt in it. This happened right after i changed the shim from 1 to 3, for some guy to learn easier, and went testing it, pushed to 33km/h and baaaam in middle of the bay. Luckily i was near the beach, and not on some of my 30km+ open sea adventures…

So… beware, your mileage may vary (literaly).

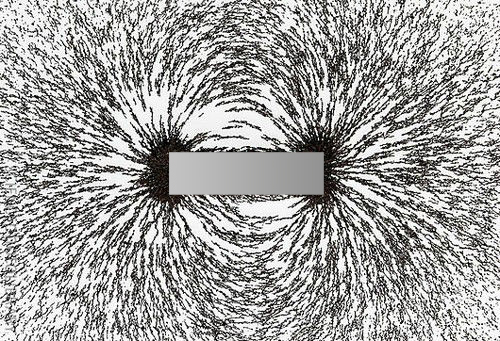

Now on the remote controller. The trigger of the remote of the newer board (v2, 9mo, ~1800km) started to get stuck. You push and it does not come back. Forget fine control, can’t even start the thing. So i opened it, and on the sides of the “axis” of the trigger there are round plastic caps, one has a magnet inside it - which has gone rusty, and bubbling up, and pressing/blocking the whole axis movement. i have to scratch quite some of that to make the movement loose again. There’s also some epoxy?glue?plastic-like piece in there, which i removed. So far so good, but i guess in few months i have to repeat the procedure when more rust forms there. BTW that magnet is THE actual control piece of the trigger, but, although the cap has some cuts for positioning, they are 2 and are equal and symmetric, and when put the wrong way, the trigger goes funny… i.e. does not work. Any idea what replacement magnet to put there, when the thing goes all-rust?

I asked Fliteboard’s support about warranty or something, they do not respond at all.

ah. Being the only one in whole country (Bulgaria) riding a fliteboard is… weird. But anyway, so far convered 3/4 of Black sea coast (14-16km per leg then back), only the northest part left. Next month maybe.

Ciao

Sviden (nickname in flite club)