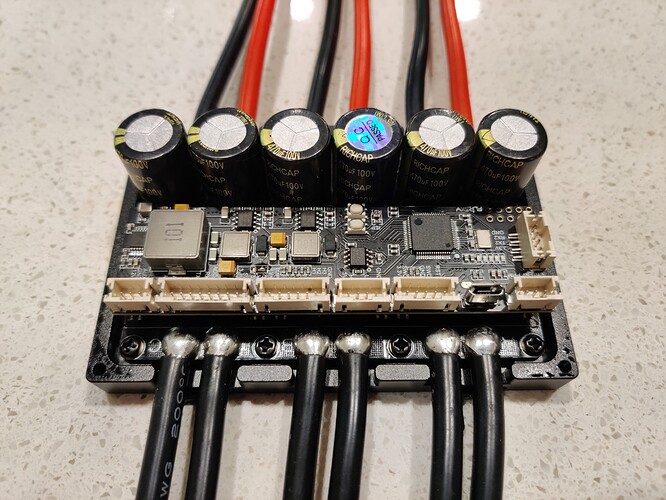

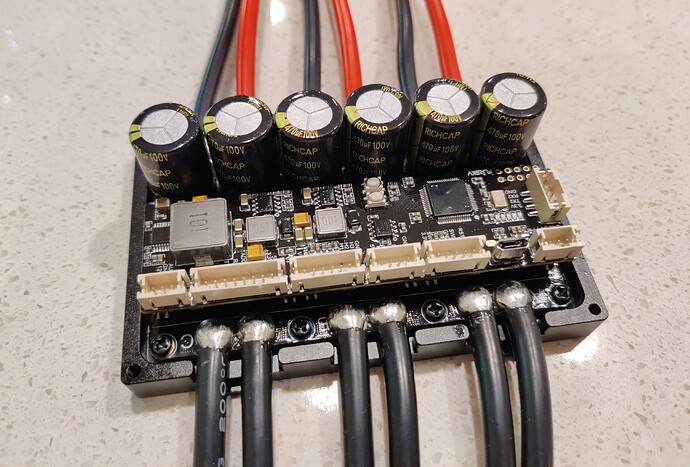

Hi! While waiting for my board and summer, I decided to conformal coat and inspect my FSESC75200. It will be going into an aluminium box, and it will be submerged in mineral oil. I’ll probably use thermally conductive epoxy to mount it, and then epoxy some thin copper tubing on the outside of the box to cool it.

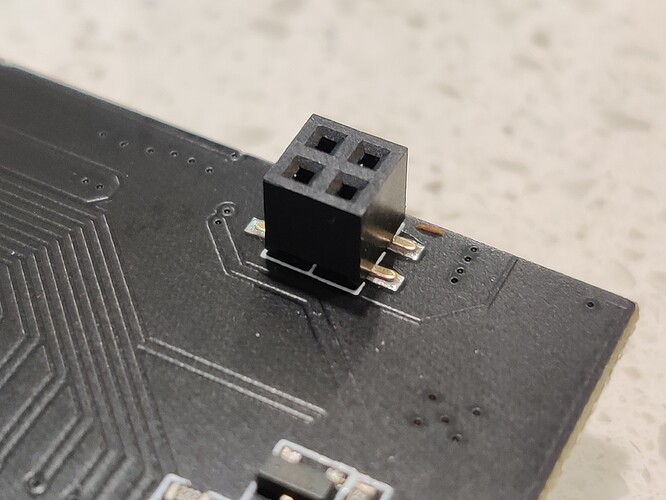

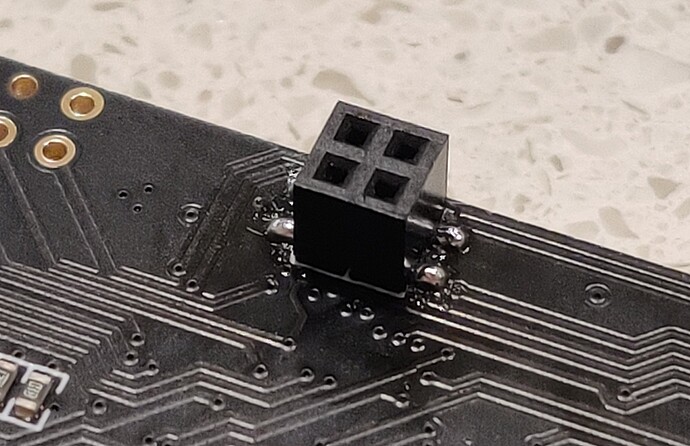

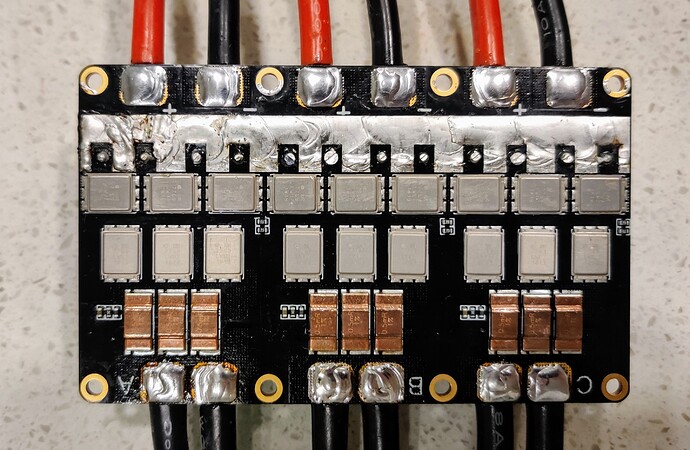

Upon first glance, without the top cover, it looks nice and clean. Minimal residue on the PCB. Solder joints look good enough, but maybe a bit on the dry side on the data connectors.

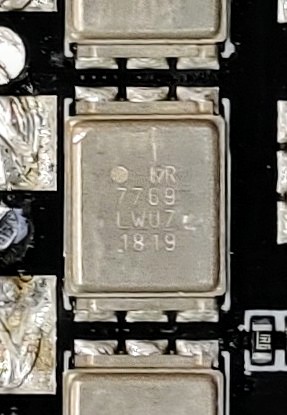

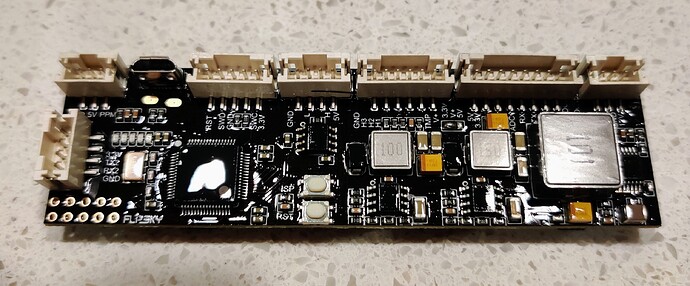

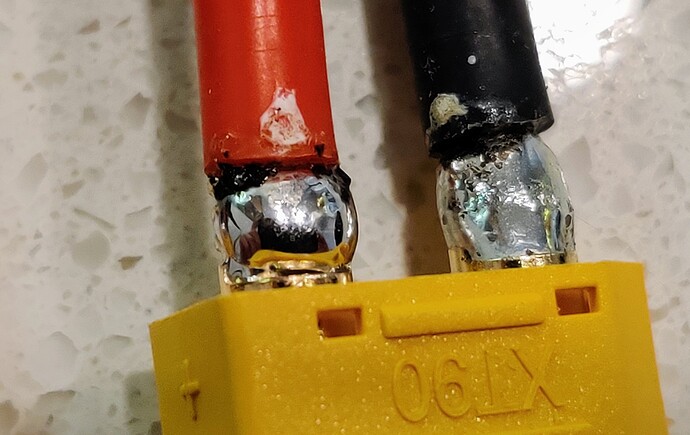

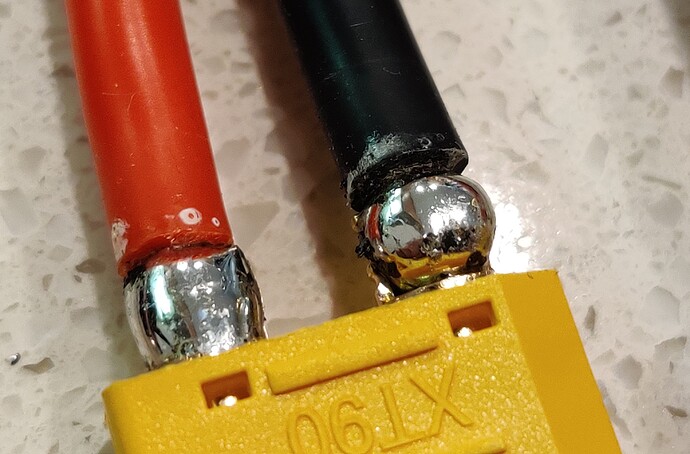

While taking off the top PCB, I noticed that one of the interconnects on the top PCB was starting to fail and come off. Luckily it did not rip the pad off, and it was actually a solder joint that failed. I think Flipsky engineers wanted to avoid melting the interconnects, but while doing that, they ended up with very weak solder joints. All the interconnects are like this. I would recommend to check yours.

Added some flux and solder to all of them. There is quite a significant ground plane on the PCB. Pre-heating the PCB with a hot air station made the soldering much easier.

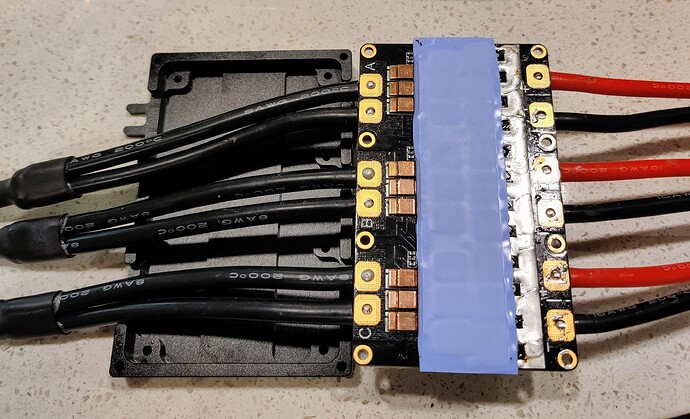

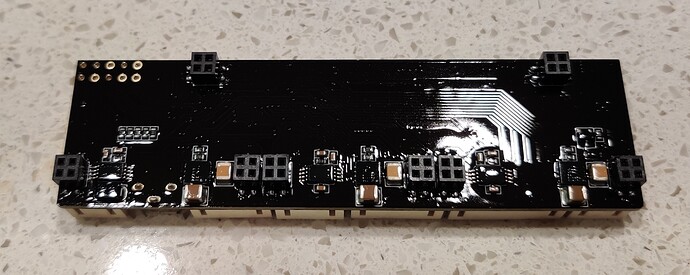

The bottom PCB looks nice as well. A bit more dirty than the top PCB, but very much ok.

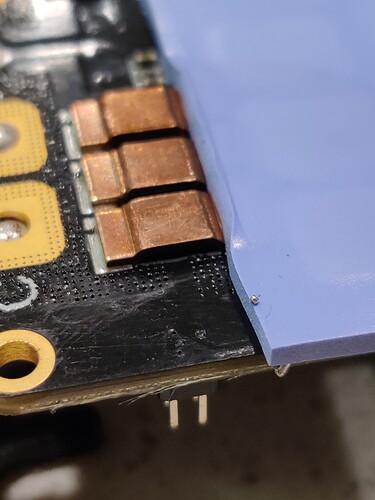

The PCB took some effort to detach, due to the semi sticky thermal pad. The pad is pretty thick. It came off without breaking, but I had to be quite careful.

I found a piece of solder that was stuck to the thermal pad. It came off easily. It used to be pressed against the heatsink and thermal pad, so it probably would not have caused trouble in the future. Inspect yours.

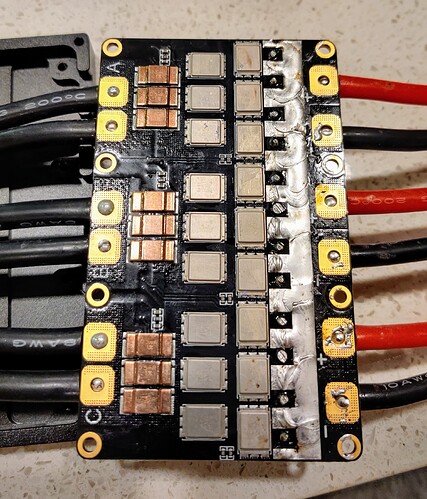

Nice directFETs. Massive ground plane as well. The solder joints on the output wires weren’t too good on the bottom side, and there was some solder that wasn’t really well connected on the golden pads.

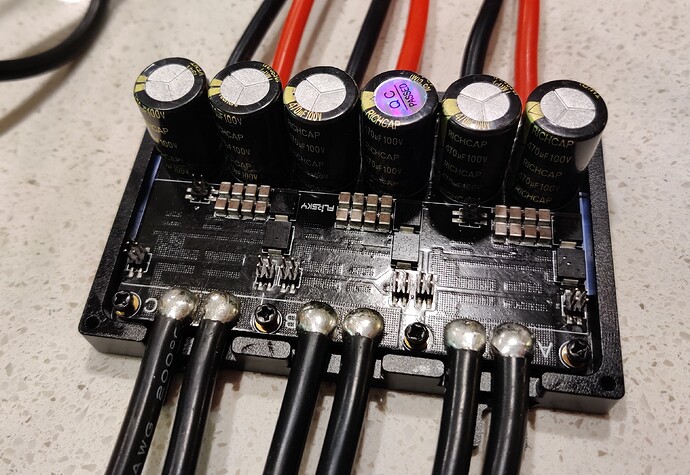

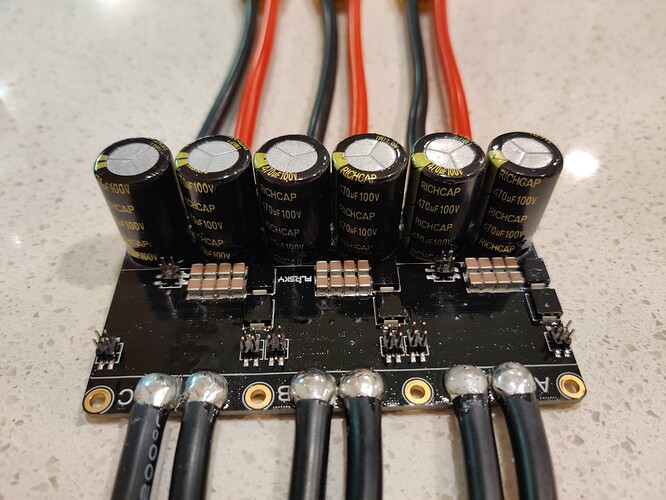

The sleeve on quite a few of the input capacitors was damaged. It looks like damage from a soldering iron. The metal can seems to be ok, so conformal coating will fix this.

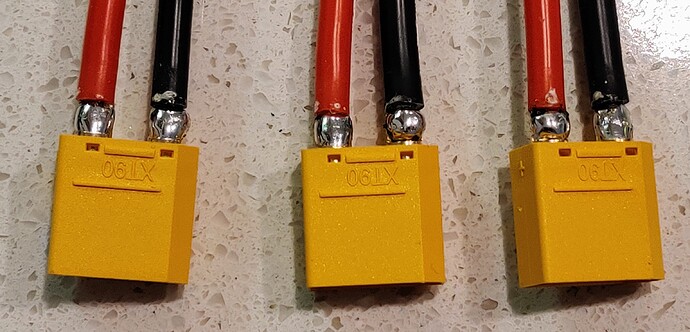

Input and output connections cleaned up. This took a while, since the ground plane is massive and sinks a lot of heat. I managed to do it with an 80 watt iron, after preheating the board with the hot air station.

I started the conformal coating process. All boards and sides were coated. I avoided coating the top of the directFETs.

The caps look pretty good after coating them. I also removed the FS QC sticker and coated the top side of the caps. I applied quite a lot of conformal coating to the root of the caps, since it nicely wicked under them. An added benefit is that it will hold the caps in place (good against vibration). Unfortunately there is nothing holding them by default.

Topside of bottom PCB coated.

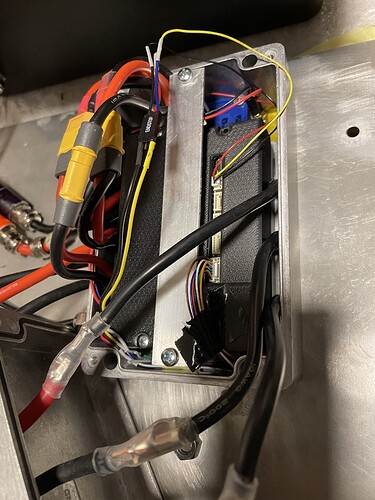

FSESC75200 almost fully reassembled. I used locktite in the screws that hold the bottom PCB and top cover. Reassembly went without issues.

Final product.

conductive pad on the whole under PCB.

conductive pad on the whole under PCB.