Thanks! I am using THESE SEALS. What are you using?

Are you sure it is not coming through the front mast clamp? Have you coated the PLA in some epoxy?

PLA not suitable for your weather

If you leave it in the sun for half an hour the print changes shape/melts because of the heat

the PLA has a softening point at 50/60° … perso I printed everything in PETG … point of rumbling 85/95° … of memory …

can be the internal heat of the tube happens to deform the PLA and more particularly the throat or the seal SPI comes to lodge … I would make you a return of the setting in water …

I see no evidence of leaks into the tube from the mast clamp but I suppose it is possible that when the motor heats up the air expands inside the tube – as Manu says – and things leak that are not apparent after they have cooled back down. I have not coated any of my PLA parts.

Has anyone modified the SealMount STL so that it can be CNC’d?

I ran tests on PLA underwater with 100% infill. They all leaked! I bet that’s where its coming in.

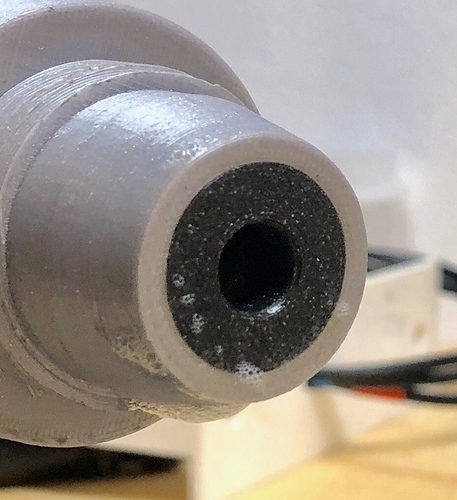

I just did a pressure test of the entire pod – rear mast clamp, tube and seal mount. I designed and printed THIS PLUG to seal the shaft hole (add a little grease to improve seal) around the tube from this vacuum pump. The pressure held steady at 500 inhg (19 mmhg / 245 psi) for several minutes with no loss. I also painted all seams with soapy water to look for bubbles and saw none. The only thing this does not test is the seal around the actual shaft so I still believe that is the likely culprit. It also does not test the other seams under heat but I expect this much pressure would have revealed any weaknesses. Finally I was surprised to note that it was impossible for me to remove the sealmount from the tube while it was under pressure. The pressure actually presses the two o-rings harder against the metal tube. So presumably any in-tube pressure due to heat would make those seals work better rather than worse.

Seal it up, submerge it a metre underwater for and hour or 2. Then check for water.

You need to see if there is a pressure loss over at least a 30min period with the air pump.

Anybody installed a Schrader Valve in their tube to pressure test seal integrity?

@sunrise305

Hi Carl,

I just read your post about your pressure test. What I dind’t understand is if you applied a pressure below the atmospheric air pressure (partial vacuum) of an pressure higher than atmospheric air pressure. The link to the vacuum pump shows a pump designed to suction and the pressure gauge in your pic looks like that. But because you applied soapy water to the seams an were looking for bubbles you had overpressure in mind?

There is a mismatch of units in your post. The pressure gauge in your pic shows 19.5 inches Hg or 490 mm Hg (9.3 psi) below the atmospheric pressure.

Hi Heimfried -

Looks like you are 100% correct! My mistake. This is in fact a vacuum test rather than a pressure test, though either will test for leaks. And yes using soap was pointless in this case. One must simply look for the pressure to climb away from its highest position (biggest minus number) to detect a leak.

Thanks,

Carl