Using an xt-90s connector for the battery is a simple solution that will prevent sparking.

Battery looks good IMO , but if I recall correctly some people here started with lipos and then switched to 18650/21700 (lipos degraded too fast?) . Not sure, please check in the forum. The weight difference is not that much, my 6S16Ah pack weights 1850 grams, so in the end the g/Wh is not important, especially in these small packs.

Ah I see, you are right, I got it mixed up.

However, my point was the efficiency (thrust) at low speed.

Isn’t it very special that the “foildrive assist” use case only takes place at low speed? It totally differs from the conventional e-foil use case. So I thougt that this could impact the prop design.

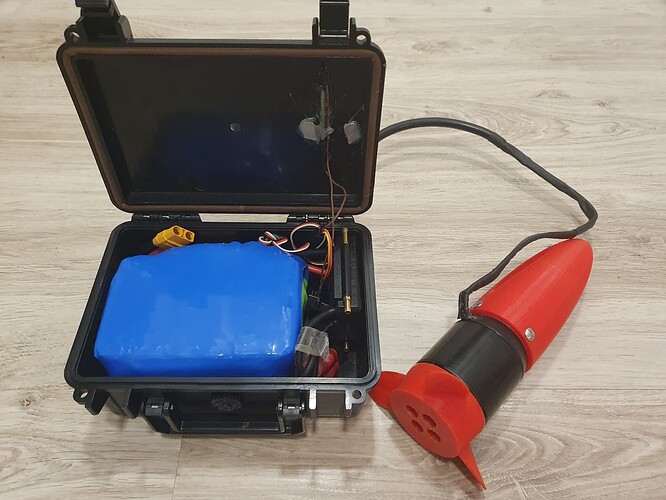

All set up and tested in the bathtub! All up weight : 2.6 kg box + 1.150kg motor+pod.

I added a reed switch that powers the Rx. The two magnets inside keep the outer magnet (to be connected to a leash) in place. Note that the reed switch must be off- centered, otherwise it’ll only ‘feel’ mangetic field lines perpendicular to the direction the switch can detect (if you use the same type of magnets i’m using, taken from an old hard drive)

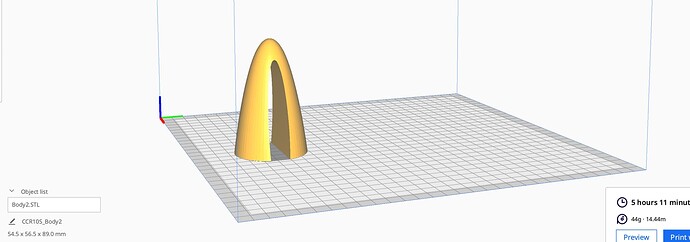

I’m also happy with my embedded nuts inside the front cone. I leave a hole a tad larger than the nut dimensions, and when the hole is complete and about to be closed, i pause the printer, add the nuts, and then resume. I’ll add the cad, bom and detailed instructions once it’s been tested.

I assume all of this is common sense and probably done before and hence not patentable, but just in case, all these ideas are released for public domain.

I am going to give this a shot too. I bought a 66112 (150kv, 2000w). https://flipsky.net/collections/e-skateboard/products/flipsky-inrunner-brushless-dc-66112-motor-150kv-2000w-for-surfing-boat-underwater-thruster-hydro-efoil

Does anyone have suggestions on the best battery configuration for this. Looking for short bursts to get up onto foil. Trying to keep things small and light, also ideally something that somewhat plug and play without any spot welding cells on my own.

Thanks

Very innovative. How do you hold it while paddling?

Good point… for the moment im trying to find the best prop for my 170kv motor, so im not taking the paddle with me, to find one that takes off without paddling. So far the 130mm prop was a failure. Tomorrow ill try with 150mm props . One with pitch/dia =0.8 and the other with 1.0.

Once it works i guess ill simply duct tape the remote to the paddle where my lower hand is normally placed and then grab it from the remote instead of the paddle.

6” with 6” pitch seems reasonable to test for slow efoiling with 170kv 6s, and you could be at around 3800 rpm. The same prop size is used at 4800 rpm on a 65161 100kv 13s tow boogie or efoil.

Much less pitch would be preferable for slow push onto swell, eg foil drive.

My perfect no wave setup.

It’s still working well. I’ve had a few issues with the motor cable splice so about to redo this connection. Seems I was getting water inside one of the cables which tracked into the box. Recently switched to GoFoil from Armie so new adaptors printed and ready to go.

this looks super cool. I’m building my eFoil but I’m also wondering if this could not be also cool to give it a go. Where can I find the STL so I can adjust them to my mast? I’ve also few lipos left from my EMTB so that can be super quick and easy to build.

How do you modify the stl? They are not parametric. If you are handy with freecad, i can give you my files when i get back to my desk

I did this print very quickly to get the footprint of my mast.

For the ESC, I think to go with this one. I was using a couple of them in my RC cars and they were performing very well. HobbyWing EZRUN 150A (6S max). I could have gone with a VESC based ESC (and I know this one will be noisy when I’ll push the trigger), but these more traditional ESCs have more punch and I’ll use “the punch on demand”. That should work well.

I’ve few 6S8AH good performance graphene lipos left from my electric mountainboard and I want to keep the setup ultra light to get just that kick to put me outside the water. I also have some p42 cells left, so I can even weld a quick pack.

Now I’m searching for the motor. I was thinking about a 6374.

For the IP67 enclosure, this one seems pretty good (reference : CHDX8-322C) and has hinges. Around 500g and ABS. 110x260x100mm (outside dimensions)

I tried to use similar ESCs with the 6374 motor, they all burned out.

oops, I may need to change … on 6S with 150A? You’re using the ESC FlyColor 150A ? no temperature cooling?

FlyColor 150A works great, two ESC FATJAY 120A and one Toro TS150 burned out.

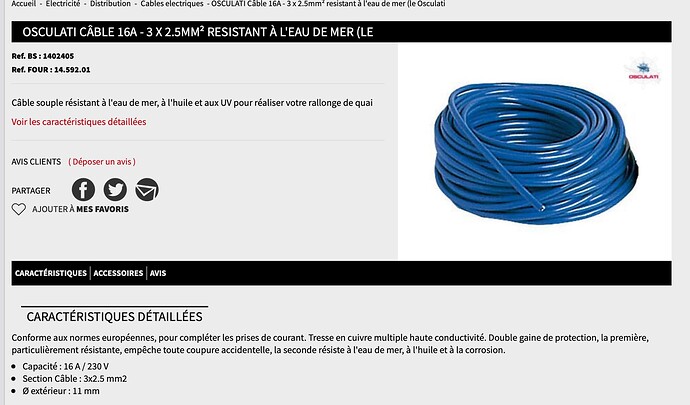

moving forward on the cable choice. 3x2.5mm marine cable is given for 16A. Overall size is 11mm

that’s not much… isn’t it?

You can use an online calculator to see your losses. Seem ok to me