Hi All,

Forged carbon fiber mast adapter:

I was looking to make a foil tuttle adapter for a custom carbon foil to my gong v2 mast and thankfully came across this file from a previous post:

I thought it might be interesting to try to make that part using the forged carbon fiber process outlined here: Forged Carbon Fibre Mould Design and Strength Optimisation - Easy Composites

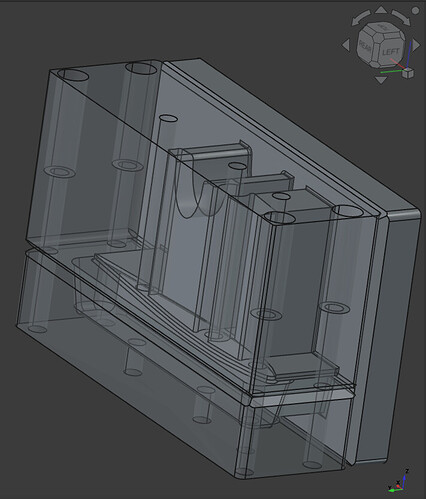

After a month of learning Freecad, coming from Fusion-360, the mold came out great!

I used bolts(not shown) and stainless shafts(x3) to hold the mold together and create the through holes during the forging process.

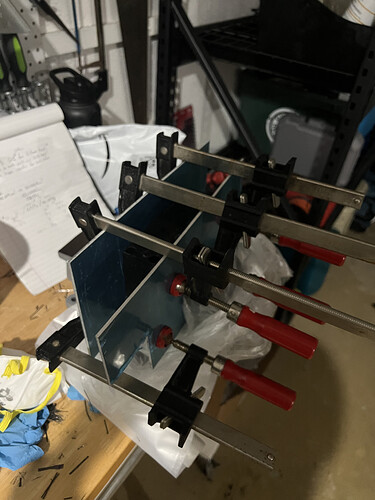

I then applied PVA, carefully measured my carbon and epoxy ratios from the guide above and clamped everything up with aluminum backing plates.

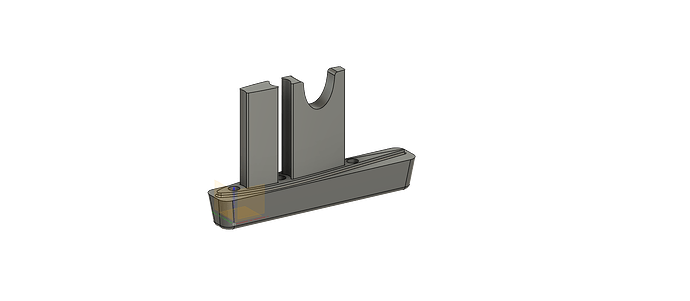

The results:

The final adapter part weighs ~100g compared to the original part which weighed ~200g and the adapter has caused no signs of corrosion on my mast because I sanded/coated with epoxy.

I’ve tested this part for 2 months so far without any failures or further notes on performance.

Contact me if you’d like access to the files!