Downloaded. Printing starts in 2 minutes. Thank you

My first water test didn’t work out very well.

Could be my print, adjusting the impeller for my 5mm pin size etc. but I only managed to get up on foil briefly.

100l Fliteboard, 10S11P 21700 battery at 41V and 85kg body weight.

EDIT

I used the 5 blade ver of the impeller for this test

END EDIT

I started with my normal XOver V2 L size 1300sqcm and could not achieve take off speed even though I went to full throttle.

I then switched the front foil to the XOver V2 XXL size 2050sqcm

Relative size of foils

With this larger foil and a lot of bouncing at various throttle and then full I managed to pop up. I didn’t want to get too far from launch point turned and touched down. Back to no ability to foil no matter what I did.

When I took the board out I realized the “nozzle” section was missing which would explain the inability to achieve takeoff speed again. It must have come off during the touchdown.

I had attached the “nozzle” with 4 screws initially but that seemed to make the impeller bind a bit. Eventually I went with two screws and wide tape around the joint area. Upon inspection one screw remained in the part that attached to the motor and the hole where the other screw was inserted looks like it just pulled out.

I will reprint “nozzle” and the additional blade impeller and try again. ![]()

EDIT

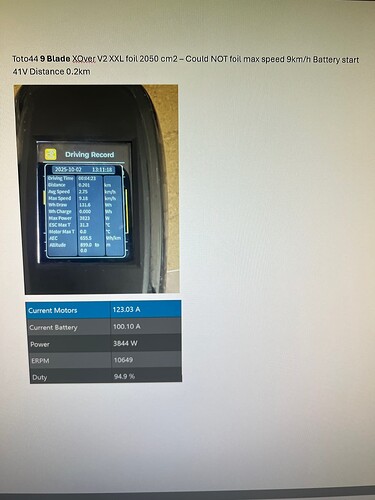

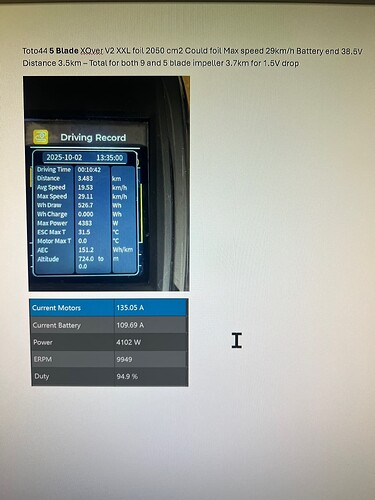

Second test today with both 9 blade and 5 blade impeller. Foil was my largest XOver XXL 2050 cm2 . Started with 41V battery. Did short 9 blade session - could not foil, Switched to 5 blade foil and by using my “windsurfing low wind get on a plane running off small waves skills” got up foiling. Performance was OK but a LOT noisier than my normal Flite prop setup, acceleration response was slower but a rider could adapt quickly to that. I intentionally broached motor twice and it was smoother than Flite prop at release and reengage but some of that might be larger front foil. Broaching is NOT something I practice so not sure on that. ![]()

I traveled a total of 3.7km for both impellers with a top foiling speed of 29km/h (possibly limited by foil size but I was at WOT) Battery V at end of session and cool down was 38.5 - So power hungry 2.5V drop relative to my normal setup. Likely because I was at WOT most of the time.

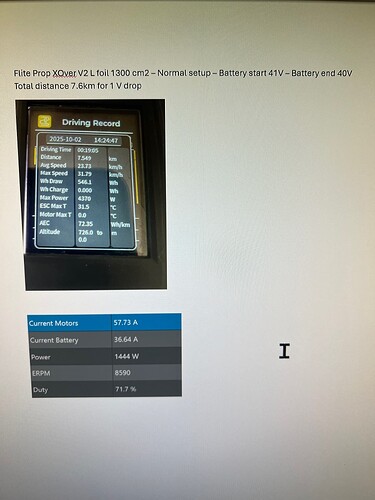

I then re-assembled my Flite prop and 1300 cm2 foil rig and went out with fresh 41V battery. Travelled 7.6km, top speed 31.8km/h and battery V at end of session and cool down was 40V - voltage drop 1V which is my normal performance level with this rig.

These results may well be my 10S battery V, and/or VESC settings etc but even if it worked on my normal foil I’m not sure I would want to ride with the noise level / pitch of the jet drive. I feel the same way about the Lift jet I got working with my big foil so not sure if this jet drive stuff is for me.

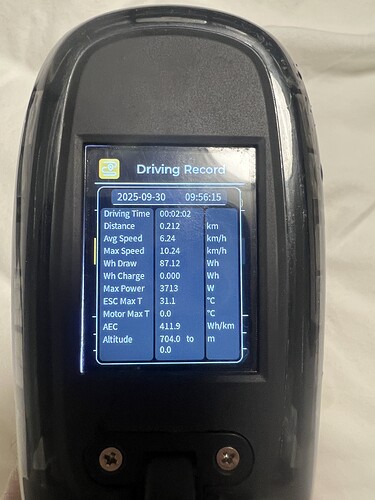

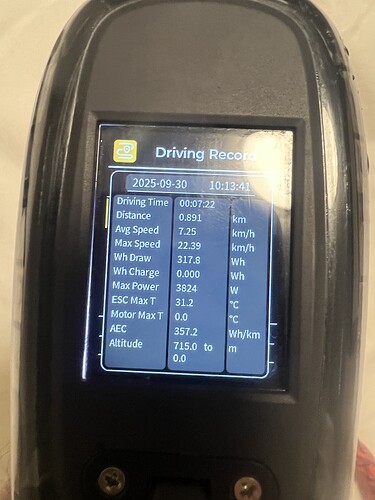

I have attached some photos below of my records. The VESC log data is a bit iffy as I just picked a sample in the range for each type and also not sure the ERPM value is correct as my vesc shows 14 poles for this motor and Flipsky says 6 poles and I think that throws off the calc. Not something I’m going to change as my current config works just fine.

This next page should read 2.5V drop not 1.5V drop

Looking forward to seeing other test results ![]()

END EDIT

Strange that you aren’t getting anywhere near 6kw. Are your current settings too low?

It would be interesting to see RPM data too.

I’m also assuming your screws were too long if they were hitting the prop…

Well, 10s is heavy on the low side. I am running this at 14s

Can’t recall VESC settings and wasn’t able to VESC log the session(s) as I upgrade the ver of IOS on that phone and now Vesctools is throwing directory doesn’t exist error. I didn’t feel like messing with that so just used the Druving Record function of VX5

In any event the VESC settings are the same as I have been using with Flite prop and a bunch of 3D printed ones and my hacked together LIFT jet drive. All work well with the

limits I have and the 1300 foil other than the Lift Jet as after V drop to around 38V it wouldn’t pop out either until I switched to large front foil.

Screws I used were M3 x 4 so they didn’t come all the way through the part attached to motor. I think the screws “warped” that rear part a tiny bit and created some friction with blade although no marks on end of blades or inside of housing. The other possibility is the surface of the inner cone of the nozzle runs very close to the face of the impeller so it might be touching there with all the screws in

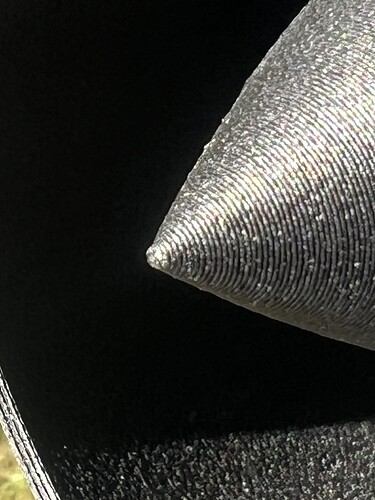

I did have to sand that area to take off the texture from the print bed as it bound when I first fitted it.

The tolerances of @Toto44 design are pretty tight which I admire but it doesn’t leave much “slack” to work with ![]()

And again: 10s will not give enough rpm. I am wondering that you where able to get out with this setup

That could well be my problem. Nice design and a fun project to work on!

I think @Kian runs a higher S count battery than me so hopefully his results are better than mine😀

It would be great for the community for this to be a solution for anyone who wants to run a jetdrive.

Not sure it’s safer though - I scratched my hand on the pointy bit of the nozzle!![]()

Yes. I have one 15 and one 16S.

Printing the new impeller now, and will try to give it a test run tomorrow

I’m having a bit of trouble with terminology that I hope someone can clear up.

My question is which part of the jet drive cowling is front and rear

@Toto44 labeled the stl that attaches to the motor “hinten” which I understand translates to “behind” and the stl part that goes on after the impeller is installed “vorn” which I understand translates as “in front”

So that would to me mean the hinten part is “rear” and vorn part is “front”.

However the hinten part is where water enters and is closer to the front and vorn is where water comes out and is at the rear of the board

???![]()

Can you let me know what screws or inserts etc. you used to connect the parts of the cowling together? I also see in the photo that you didn’t use all of the locations either

I am using M3x4. Maybe this section is a little weak. If you are interested, I can add some material there. As I mentioned before, I drove this unit only 1 time for maybe 30 minutes, plus some testing in the pool to check Amps. So I can not say anything about durability.

Maybe add a “twist to lock” part would help too

What numbers did you get with your initial test?

So same as what I used. Can’t really be longer or they would protrude into the inside of cowling.

Maybe the Bambu PLA-CF I used let the threads tear out. If you didn’t have a problem and if @kian doesn’t that would imply that might be the case. Nice to know that if it does come off you are still able to power back to launch site.

I reprinted the part I lost so will try again with the additional blade impeller version once I get it printed ![]()

@kian idea of thread on is good and maybe thicker and/or longer overlap would help, Countersink screw head hole would reduce cavitation

EDIT

Thought it might be helpful if I posted some photos of how Lift did their original jetdrive.

The approach is similar to @Toto44 design in that the part the water exits from goes over the part that connects to the motor. Lift has 4 screw holes but there are inserts in the motor connected part. There are also 4 locking in areas that hold the parts together by applying a small twisting motion. This might be better than a threaded on solution but I couldn’t do either in CAD so what do I know. To me threads might get cross threaded or bind somehow and make it really hard to get the parts separated.

Motor attached part

Water outflow part

Comparison of Lift “impeller/prop” to this designs impeller and this designs motor attach part

END EDIT

EDIT

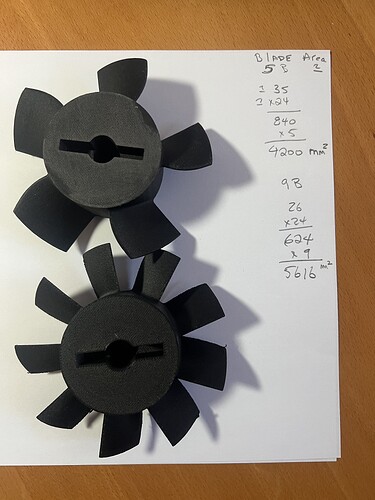

Comparison of blade area of the 5 and 9 blade impellers

END EDIT

In theory, this blade shape, combined with higher RPMs, should result in a reduction torque effects for single-motor tow boogie configurations?

Well I would have replied but I had to Google the “reduction torque effect” terminology you used so I don’t think you would have found my post particularly useful. ![]()

Happy to see you are going to test as well!

Sorry. I was going to test it today, but forgot that I had driving lessons.

Tomorrow is also a no go for me.

Can you tell me what filament you used, which impeller ver and what S count your battery has?

What I meant was that the stream from such a propeller is more like the jet stream from a Jet, and there should not be any obvious roll of the board onto the side.