Same size as the gong , just a little harder to take off , wall are around 2,4mm

Same bolts

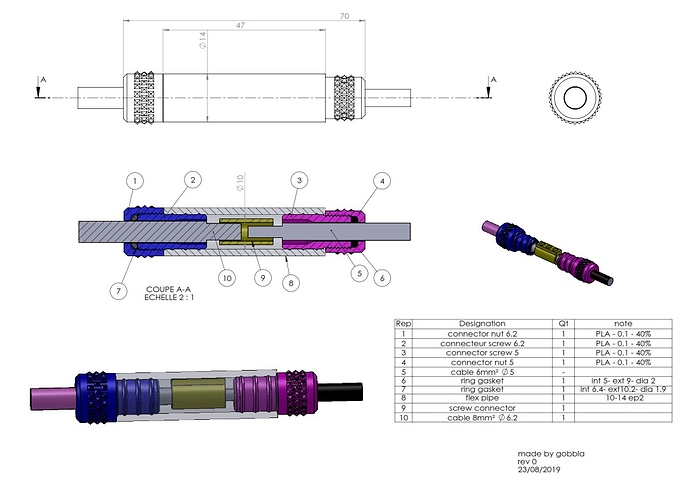

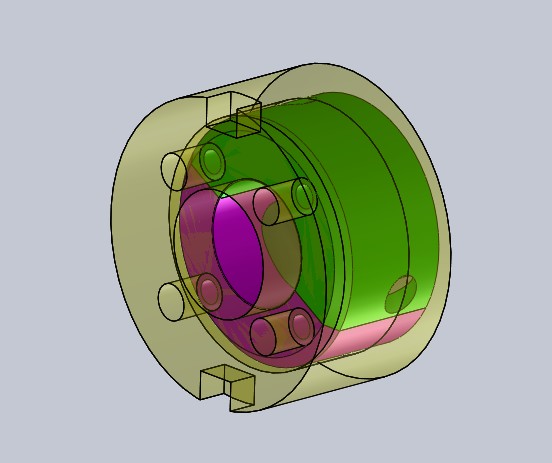

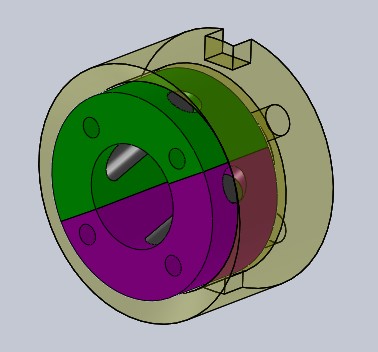

Very nice XT90 waterproof shield. I have a few questions:

- how is it going after 6 months of use ? Is there anything you would like to modify ?

- which 3D printing material did you use ?

- can the model be enlarged to receive XT150 connectors ?

Thanks.

If you want an earlier take-off, just place 1 to 4 layers of soda plastic bottle material (cut like washers) around the rear screw of the stab between the fuse and the stab. This will create more downward lift at the stab level when you take speed therefore a faster nose up for the front wing therefore for the whole foil…

Sorry I mean take out the takuma mast from the gong mast plate and fuselage

@SoEFoil regarding XT90 shield, i have replace aluminium tube by plastic tube, it’s work fine.

you can see after a long ride some water vapor inside, maybe due to heat inside and cold water outside.

i have replaced XT90 connector by screwed connector,just due to lack of time

i use cheap PLA, it can be improved with other material, but i did not spend time on it

No problem to modify it for XT150, i will check tomorrow i have 3D model, maybe fit inside without modification.

one improvement is to found some more flexible pipe to connect both side, my actual one become less flexible after some time.

improvment of the weekend : charging station :

1.5h to charge 1 batterie, and more easy to transport (before it was a mess of wire)

Use silicone tube. It’s more supple than plastic and will handle heat much better.

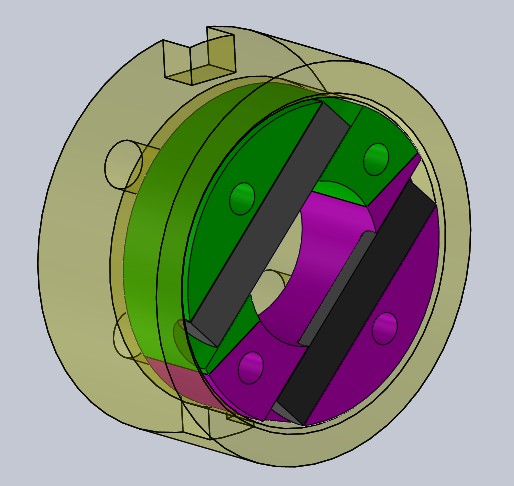

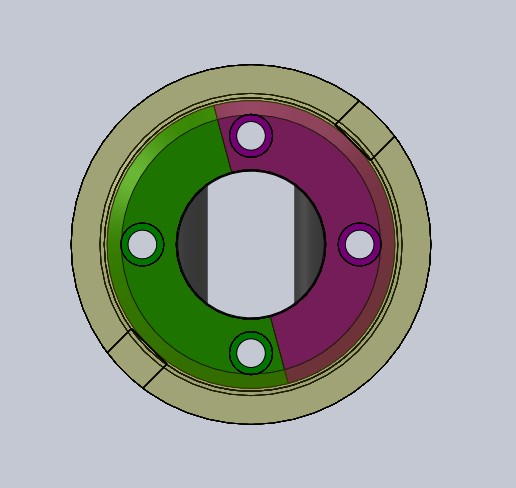

new proppler ==> new problem ==> new solution ![]()

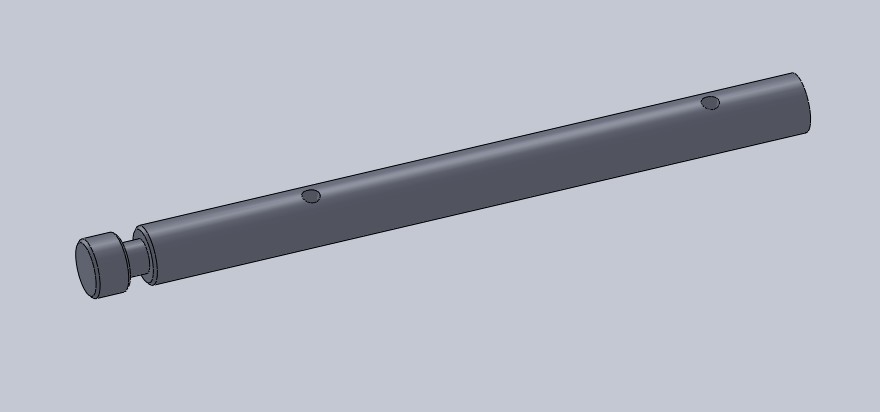

my design of propulsion has to be used with pin to lock proppler (chinise alu prop)

but FR proppler has to be fix with nut ?

solution : 3D printed part with 2 pin :

tested in real condition … it’s work

I printed your waterproof connector for XT 150 and the result is good. Only note: I find that the hose fits too easily and does not have enough resistance to be waterproof… do you put COLSON type clamps to tighten the tube on the connector?

Thank you.

i dont use colson type clamp, in my case resistance is high.

it can be a good solution.

you can try to increase external diamter of connector ?

somebody advice me to use silicone pipe to be more “waterproof”

can you share pics ?

thx

This would have been a solution indeed, but as I didn’t have the file in 360 fusion format I ordered a 9x12 pipe instead of the 10x14…

For the moment I’m just using it to connect the negative pole between my battery in a separate compartment from my ESC compartment.

I would like to do the same for all three phases in order to be able to disengage the mast from the board.

I received the silicon tube in ID: 9 OD: 12 and it goes great with your XT150 mounted connection device.

Tube ordered here:

https://fr.aliexpress.com/item/32981788796.html?spm=a2g0s.9042311.0.0.40596c37rYgqMQ

Bonjour à tous ! Félicitation pour vos travaux ! J’ai uploadé le projet il y a de ça quelques mois et je me suis mis à vouloir le produire. Avant cela j’ai analysé un petit peu votre système pour peut-etre l’ameliorer et suis arrivé à quelques conclusions que j’aimerai que vous validiez par votre expérience. Vous êtes partant ?

Nice hatch. It is more thinner than Nuova Rade hatch.

Salut, avec plaisir pour partager et améliorer,

peut être en poste privé si l’on reste en Francais ?

tu es dans quel coin?

Salut Gobbla, Je suis sur un projet et j’aimerais en discuter avec toi si c’est possible. Je ne suis pas très loin de Lyon

Salut, avec plaisir!

Je n’arrive pas à trouver comment envoyer un message privé. Ca sera plus pratique par messenger peut-être non ?

Hi @Guillaume you cannot post a private message at the beginning of your registration, you need a certain seniority before accessing this function. And a piece of advice: post in English because some members will not hesitate to send you a private message at reprendre😉.