Hi Manu , thanks for your reply ! I’ll remember that for my next posts.

How you design this “enlarger”? You just made section bigger for required cables or …?

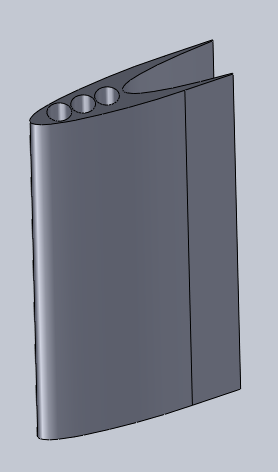

just 3D printed extesion for cable

one more hole is possible for watercooling

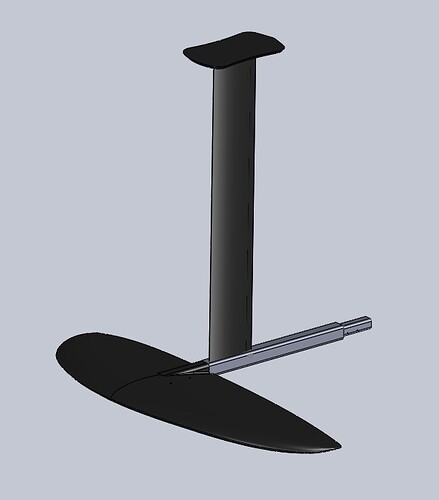

some new idea.

when i face problem it is difficult to repear on lac side. lot of small screw, cable are so difficult to move inside the mast. buying another foil ? or just the mast ?

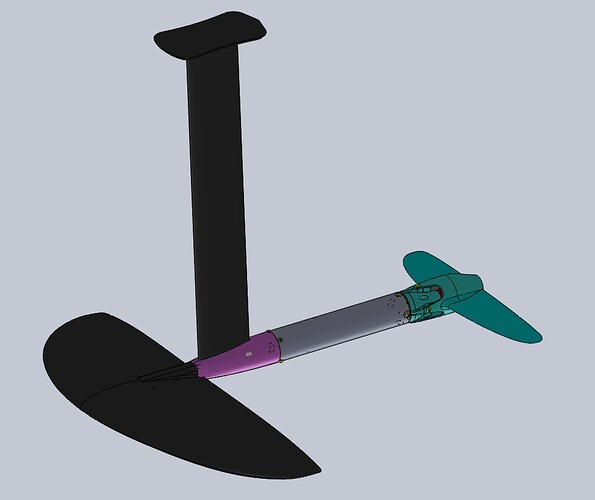

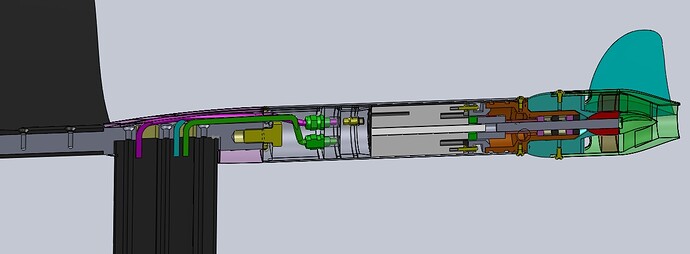

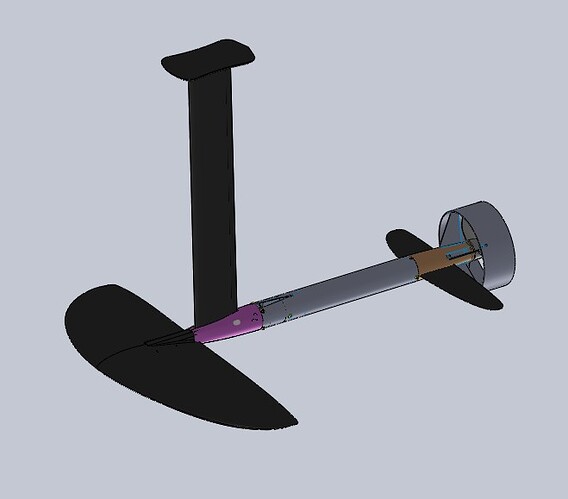

So i m exploring some ideae to change easyly complete motor assembly

still using gong mast :

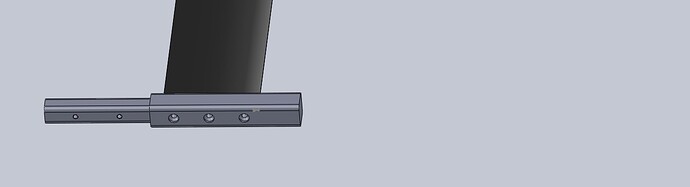

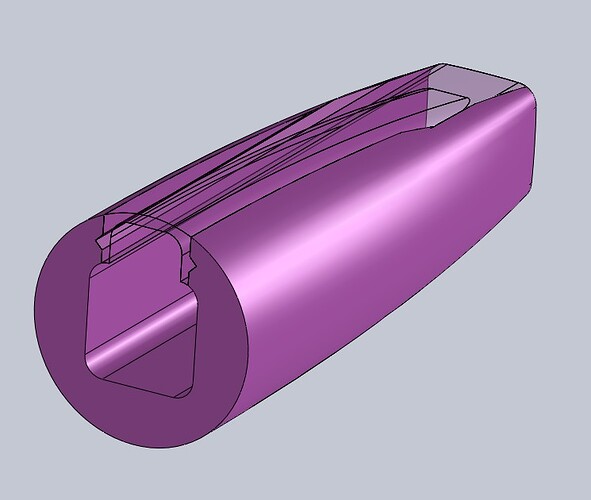

cut aluminium body :

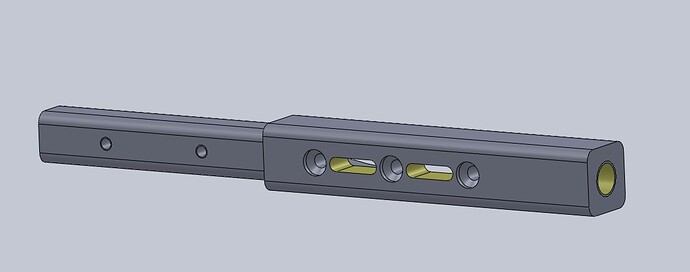

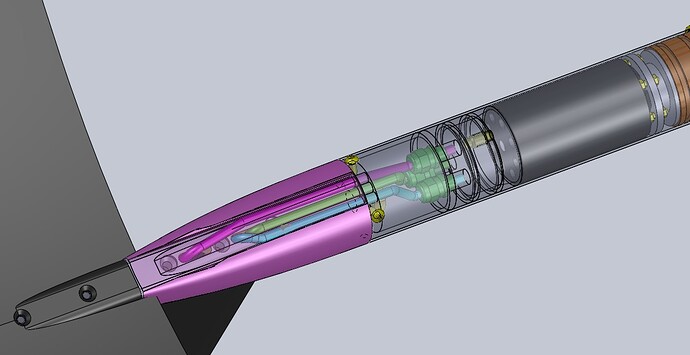

make slot for cable + threaded hole M16 :

fix aluminium part :

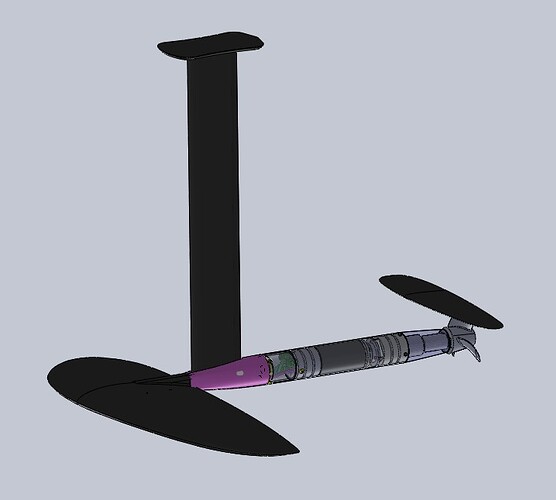

place some 3D printed cover to reduce drag :

bottom of cover can slide to easyly place cables :

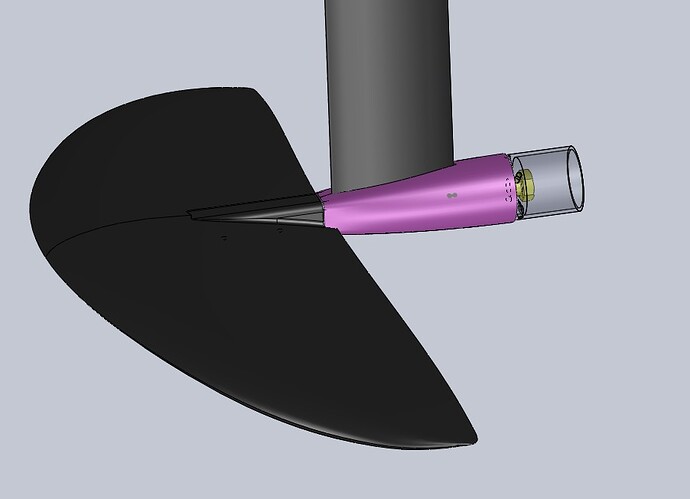

compatible with my first motor :

compatible with any motor if diameter of alu pipe is the same :

what do you thinck ?

Great Idea ! Just only « bad thing » : if you hit the bottom the motor unit would be dommage as well

The last rendering scares me a bit. I think the position of that prop might make it more dangerous.

thanks for your feed back, i wil try to finilyze jet propulsion first.

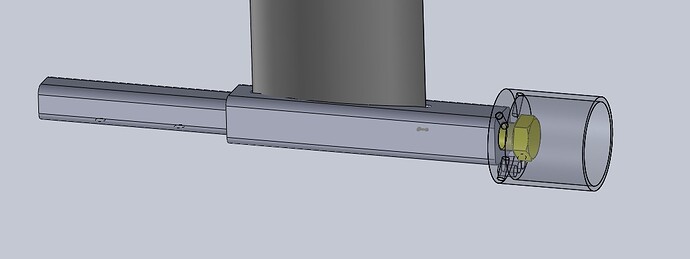

i have made prototype to see how it can look like.

it really solve problem of hole in mast, really easy to place cable,

very neat design by integrating this in the mast. Curious about you result on the water with a jet.

Very nice, a second no-drill mast philosophy project. Self maintained 3D printed cover ala Slingshot + the sliding plate are very clever. What about the stiffness of the assembled fuselage ? How will the unique big bolt bear the vibrations ?

Beautiful ! Well done , so is it Onean or MHz 64 ?

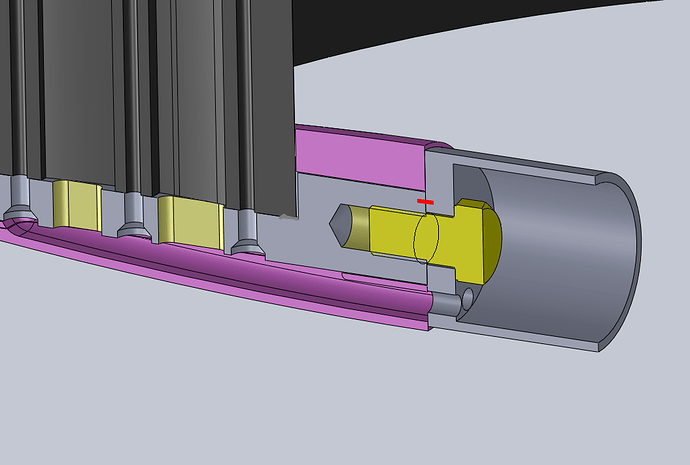

for the unique bolt it is M16 A4-80, i did not make calculation but seems enough.

For me most of the load is coming from the mast to the front wing and in this region i did not make modification. Gong design seems strong enough.

On back , i can do calculation but i need the force of rear stabilyser. i dont know how to estimate.

For vibration, i will add spring washer, uner head of screw. I had the opportunity to obtain TREP washer SS steel.I dont think vibration will be a problem.

My concern is more on should i place pin to prevent rotation of back part? (in red on below picture)

will see in real condition in spring season.

Thanks, MHZ 64, my old one.

@Gobbla , I have bought an eSurf from China, I would like to improve it especially Waterproofing of the board. Would you be interested to see it? Can we have a tchat?

Hi, great Job, i live also at Lyon. I expect to start during this winter my efoil project. Thanks for your support. Best Regards

Eddy