The next step is to test the durability, going on this weekend.

When all is okay I can help you to get the stuff.

It seems to be difficult for maedler if the customers live not in the EU, in Germany,

they ship to everyone within 2 or 3 days, if in stock.

Awesome thanks! I look forward to seeing the test results.

can you share your drawing, in solidworks file is OK. thank you

Me too. Am happy to return the favor too!

Ah just as I had finally decided on just buying a gearbox… Its sweet to see it working!

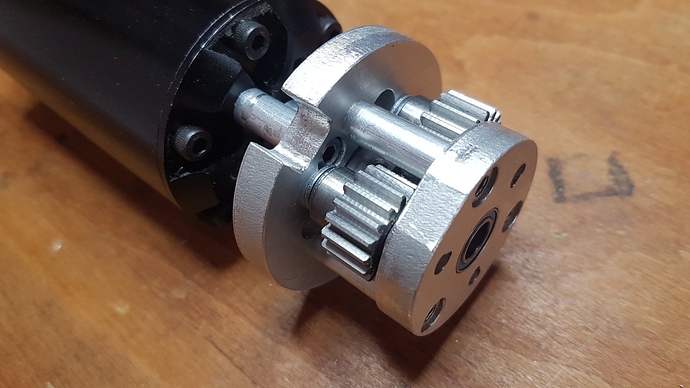

It’s fantastic! Can you post some photo if how it’s attached to the motor and propeller shaft? Self building gearboxes is the answer!

Your gears look stronger than commercial gearboxes as well, probably because of no backlash restrictions (we need resilience, backlash is not an issue for us).

Awesome breakthrough. Thanks for sharing. Love your waterproof remote too!

What is backlash? 20char

Backlash is the delay in output charge of direction when the input direction changes. This is important to worry about then using gearboxes for precision machinery/tool but not a consern at all for an efoil.

Are you now using all off-the-shelf gears or are some of them still custom-made from your files? Best I can tell you are still making the internal ring gear?

Exactly. Without this restriction, we should use thicker teeth gears, better for our purposes

It`s all steel, see the picture in post 76.

The high load ist the one problem, the temperature in the tube the other.

With the experiences I have meanwhile, my opinion is that there is no chance to realize it with any plastics.

POM did not work really long and PA6 is not (good) printable with a normal 3D printer.

I chose modul 1 teeth because there is all needed available at maedler and it works in my 3D Helicopter, there are peaks of 165 Ampere, a lot, too.

@2D-Foiler would you be able to post your BOM for the the gears and ring? I would like to try this ‘when’ my Chinese gearbox fails.

I`ll actualize the list of materials and the CAD files this weekend, then you can download it from dropbox.

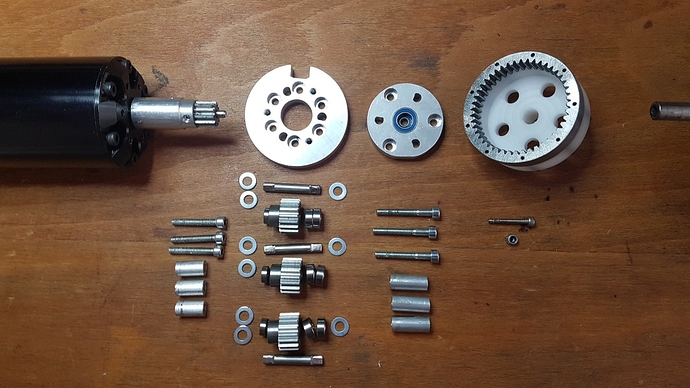

Here the actual gearbox, it is now 4.1:1.

The list of materials and the CAD files are here:

It took much more time than expected and it`s more work to build, but the first trie was not stable enough,

so I had to remove all plastics and replace by steel or aluminium.

Best Regards

Andreas

Nice work! I am curious how well it will hold up!