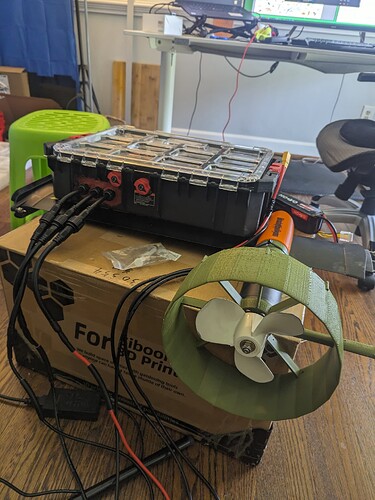

Dear Experts, I constructed an Efoil this winter, utilizing a Flipsky FSESC 75350 and a 65161 120 KV motor. Initially, everything is operational with a 12S LIPO battery system (~44 volts). However, in order to increase speed, I added a third battery to upgrade the system to 18S (~74 volts). At this voltage, the motor fails to spin, which is puzzling as both the motor and ESC are rated for up to 20S (~84 volts). I have already tried swapping the motor cables, but this did not resolve the issue. When I use 12S (~44V) it works fine. Could you please advise on potential solutions? Any guidance would be immensely helpful as I am eager to test this Efoil on the lake. Thanks,

Sean

This motor delivers enough power on 12s, so at least in the beginning there is no need to go for 18s.

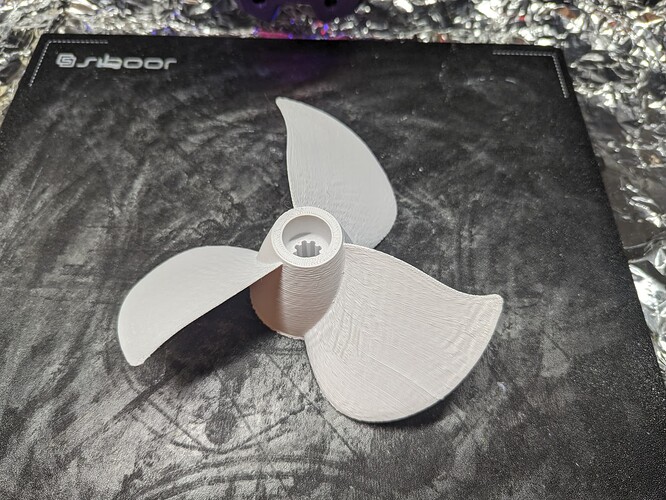

What I can see in your pictures you might want to change your propeller. The size of your prop guard indicates that you’re using the original Flipsky propeller?

The system will run more powerful of you take a suitable propeller!

Hi thanks, it’s the original prop, and I will tweak that later, but i really need to figure out why at 18s it doesn’t do anything. My guess is maybe some setting in the esc configuration. Last week I tried it in water with 12s but I need more speed since I am still learning how to foil.

Did you set the battery and motor currents to 150-200amps yet? If you left them alone after the motor wizard they will be too low.

Imagine modifying a car by installing larger tires than specified, increasing rolling resistance and altering gear ratios, similar to using an oversized propeller on an efoil. To compensate, you might consider boosting the engine’s power to overcome the increased load. However, just increasing engine power does not solve the core issues like handling and wear on the drivetrain, much like raising the voltage on an efoil doesn’t properly address the extra load from a large propeller. The right approach is to use proper-sized tires or adjust the drivetrain accordingly, just as using the correct propeller size would ensure optimal performance and system integrity on the efoil.

I agree the original prop is a waste of time. I cut mine down to 140mm OD and it worked ok but the flite prop I now use is much better.

Jumping from a 12s to an 18s setup in your eFoil significantly ups the risk of electric shock, especially around water. Here’s the lowdown:

12s already needs caution because water and electricity are a risky mix. It’s under the 50V safety threshold but still, you need to watch out.

18s steps over the line big time. It’s way more likely to give you a nasty shock if something goes wrong, and water around ups the risk even more. Higher voltage can push electricity through your skin easier, making accidental zaps more dangerous, potential life threatening!

I am running 12s and with that motor can go over 40kmh. Forget the 18s and just change the prop. You will save time and be safe. I am changing to 10s this season.

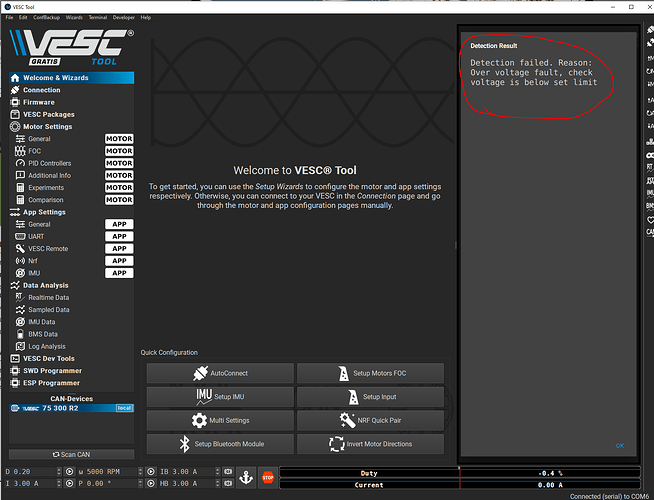

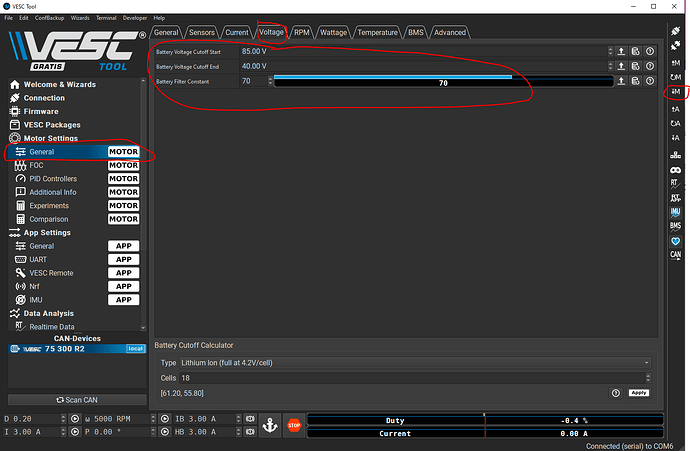

@windego you are absolutely correct. I am having difficult time with VESC Tool and not sure where and what to set. After I connect and run auto detection, I get the over voltage fault error , basically telling me I need to change those settings to match 18s. Under General I made following changes to defaults but I dont think I am writing them back to ESC firmware correctly. Pls see the attached photo.

@tosh.jah , Thank you, point taken. Do you have a recommendation for a decent propeller on Amazon where I can find one? I am using the splined version of the 65161 motor. I built a Voron 2.4 printer to create parts for this eFoil. If there are no suitable links for purchasing, do you happen to know good link to STL I could print on my own? I rather buy. The prop I am using is around 7.5 inch in diameter but looks alright, but I agree, seem too big for what I want to do.

@windego if you are using same motor, do you have a link to prop preferably in Amazon? I am not having good luck finding smaller prop for splined shaft. Shortening the blades and balancing is not easy either.

The fliteboard prop from them can buy online. But since you have splined shaft there will be some tinkering required. Most of us got the3 round shaft for this reason.

The voltage setting you have are incorrect. Let me see if I have a screenshot for my setup.

Watch this video it will answer more than you have asked ![]()

One point is I don’t think you should do the firmware update due to the phase filter issue. If you get that wron with the new firmware you can burn the vesc. I am running the original shipped firmware on 2 of the 75200s all good.

propeller

You either will have to cut your propeller, just use the search function. Several people did it successfully.

Or you can print this one shared by @sat_be

Or you can buy the one @windego was recommending and make it fit to your shaft.

Thank you all for your excellent advice and feedback, especially @windego & @tosh.jah . I ended up reducing the propeller diameter from 7.5 inches to 6 inches and balanced it well enough. I already notice a difference in how fast it’s spinning in the air; can’t wait to take it to the water. Also, I went back to using 12S.

This project has been a great journey so far. In order to learn wing foiling, I ended up putting together used CR-3 printer to build a Voron 2.4, so I could construct the eFoil needed to learn how to wing foil. LOL, and, now I know how to balance a boat propeller ![]()

Once I am done with this project, the next one is a solar-powered inflatable SUP pontoon boat, since I can reuse all the parts from this guy. Cheers!

@windego If you have the correct settings for the ESC screenshots, please post them here for future reference. I’ve reverted to using 12S. The earlier screenshots were from when I attempted to use 18S, but those settings were incorrect after further investigation. I also updated the firmware a while ago; it was challenging to get it working, and I’m not planning to update the firmware again. ![]()

If you remove that duct it will probably run good enough on 12S.

Good to hear you have returned to a safer voltage and cutdown the prop. I started with the full size Flipsky prop and quickly realized that the people here who said it was too big were correct. ![]()

Thank you @tosh.jah and @sat_be for the STL. I adjusted the shaft diameter to be 0.1 mm wider, and it now fits the Flipsky 65161 120KV motor perfectly and tightly. I’ve attached the modified file and photos for reference here: Flipsky 65161 120KV Splinder Shaft by seantab - Thingiverse

The images show prototypes with a 15% infill. Currently, I am printing a version with 100% infill, which should be ready in 4 hours, provided no chocolate ice cream hit the fan. If this work, it trumps the the prop I made earlier by cutting each blade by .5 inches. I will update and summarize everything for future reference once I actually test it in the water.

![#008-1: VESC Setup for eFoil [Flipsky 65161 & 75200]](https://img.youtube.com/vi/QaVPISP8BF4/maxresdefault.jpg)