What do you base this on?

Typical EFoil rider cruises at 30 km/h, probably not much different that typical wingfoiler.

World record wingfoiler is 77 km/h

World record Efoil is 66 km/h

Either of these records is insanely fast on any foil

What do you base this on?

Typical EFoil rider cruises at 30 km/h, probably not much different that typical wingfoiler.

World record wingfoiler is 77 km/h

World record Efoil is 66 km/h

Either of these records is insanely fast on any foil

I base this on my experience with radio controlled planes: As soon as the motor is powerful enough, aerodynamics become less important.

Or as Enzo Ferrari said: “Aerodynamics is for those who can’t build engines”.

This is certainly only true for efoilers like me that still have a lot to learn.

This is the resume of “The Bear”. A lifelong passion spent in watersports so the things you are attempting to decode he has likely already figured out.

It’s great that you are passionate about the science of all of this but important to remember the practical real life data that’s already out there😉

No, basic foils seem pretty simple, at least the first 90% as you wrote.

All my foils worked well enough and yours does look well designed.

I was trying to say, how it is really hard to attach the way a foil rides exactly to any one of its attributes, because they mostly influence each other.

Did you compare your foil to any other “known” foils?

From looking at your layup, I would expect the wing is not nearly rigid enough.

I stopped doing my own foils, when I noticed how even with 18 layers of uni directional carbon the wings were too soft to know if the instabilities in flight were due to my design or simply due to the layup.

Most brands did switch to ultra high modulus carbon layup, which is really hard to get your hand on.

In the beginning of mass market foils, many wings used winglets.

At this point, no company uses them anymore, as far as I know.

I just want to have fun designing and riding my own hydrofoils. I am 30 years too late to this, but still having a lot of fun thinking about all this!

I only have one commercial beginner foil from waydoo that I can compare to. The rest is a bit too expensive at the moment.

I am surprised that my wing seems to be rigid enough up to now. The core itself (PLA+) is very stiff compared to foam. I have only a single layer of 160 g/m² glass + some carbon rovings. It is probably stiff enough because it is pretty small and has low AR and 9% thickness. The next wing I am making will have higher AR and will be laminated with 160 g/m² carbon. I will try to use vacuum bagging.

How would I notice that it is not stiff enough? It feels very good up to 35 km/h. I didn’t try more at the moment.

If you have access rent a Fliteboard or Lift for an hour and try that. You will know what a good efoil - foil should feel like.

To me Waydoo has a reason why they are less expensive than these other brands who have been at it longer so perhaps their foils are not quite as good. I have never ridden any of these myself only Slingshot for a short while before I went with Gong so want to qualify my “guidance” ![]()

Guess it is hard to explain, if you do not have a reference.

Speed in a straight line will not be a problem.

If you turn hard or have some turbulent water, a soft foil will feel increasingly unreliable, making it pretty hard to turn in an efficient way.

Small size and low AR will help.

9% is less than most foils I measured.

F-One, Axis and Duotone all were in the range of 11-12% last I checked.

Probably also to get them strong enough. Many of the newer wings have like 100mm chord at 1000mm span and going from 9% to 12% get stiffness to 175%.

Thanks for the info. I think I will just buy a used sabfoil leviathan and make an adapter. Then I can compare and play around. Do these also work at approx 3 deg angle of incidence?

Or maybe this one? Looks like a square adapter would be easier to manufacture:

I do not think many release info like that.

All the newer Axis foils have 1° angle of attack of the frontwing to fuselage and 1,5° stabi to fuselage, so 2,5° total.

If you can get used Axis wings for a good price, that also might be a good option.

There has been a guy, who did a 3D printed fuselage for those (including 3D model), so it could be easy to adapt. But I did not try it.

I did some research and may have a lead for you to explore. My intuition about the fence changing the handling characteristics told me to think about the spanwise flow on the wing. After all, that is really what the tip controls. So if the span wise flow on the top vs bottom is affected, how could that change the performance?

From my preliminary research, it seems like the roll stability is coming from the vortex on the wing tip. Because water is so viscous and dense, a vortex which is “attached” to the wing tip will damp the roll rate significantly. Think about basically a balloon which is trying to move water out of its way as you roll the board, that is what the vortex can do.

Notice how on aircraft which prioritize efficiency, the tips are facing up? Upward pointing tips works to minimize the vortices much better. Reducing the size of the attached vortex allows for quicker roll rate.

In summary, the tips down creates much more span wise flow on the top of the wing and a larger induced vortex on the tip. This vortex is attached to the wing and becomes a factor in the roll rate or stability of the wing.

I would check the power efficiency of the wing with tips up vs down at a lower speed near stall where the AoA is high to validate this theory.

Fun topic, thanks for sharing! Great to see your creativity and motivation to test new ideas!

Experimenting is fun AF, hope you keep at it! I think of it as a car or bike on a banked track being similar to front wing tips down (or edges on a snowboard), and the inside tip grabs or digs in. Upward tips allow the wing to slide or slip and not bite into a turn (like soft rounded rails on a surfboard). I have found the opposite on the tail and upward winglets seems to lock in the feel more. Trying popular brand designs quickly adds to ones knowledge of what works, and I needed to reach a level or proficiency to really understand and feel what a foil is actually doing.

hey, that’s an amazing work!

are you still looking for suggestions to try? you should be careful about choosing a RC-plane airfoil, they have much lower Re-Number as the foils we use, and therefore are much thinner.

You could get away with a thicker profile which would give you a wider range of speeds where the airfoil performs good. On the other hand a thinner profile will produce much less drag.

I am also quite surprised that your wings hold on, i had a wing failing on me despite it had 5 carbon layers, more about that here (in German). How many layers do you use in your wings?

I am working on a tool that predicts the drag of different wings, it is still not finish but it could help if you are planning a new wing.

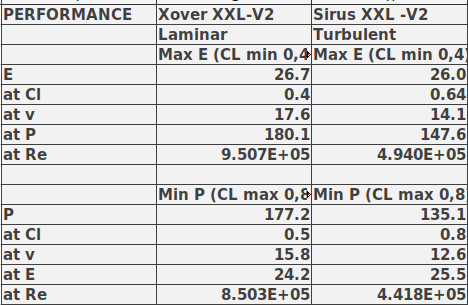

here some results from comparing my Gong Sirus XXL to my Gong Xover, for my 100Kg of pumping setup (it ist just the Front wing drag):

Have you seen this: https://www.reddit.com/r/Wing_Bot/comments/op6poq/wing_bot_welcome_and_download_software_here/

It is pretty nice, but it also highlioghts some of the problems.

It is really hard to know what the actual parameters are, when using a foil the way we do.

Chnaging the NCRIT value completely changes which profiles work best.

Interesting, interesting, so much to read and try…! I now bought a Gong Veloce L and am looking forward to comparing it to my designs. Wing twist (washout, area and thickness all look very similar, really curious to see if it behaves completely different). Unfortunately, I am a Warmduscher, and I think it’s too cold already in Germany for testing ![]()

On my finished wing, I am using just a single layer of glass (approx. 160 g/m²), and a few very thin carbon rovings. I am a beginner, so the are no sudden changes in angle of attack that would stress the wing too much. But how is the wing centre designed in commercial wings? I attached a screen shot of my design. I have some thick carbon rods along the wing, some thick aluminium tubes that take the bolts, and an aluminium plate on the underside. Everything covered with an extra layer of 160 g/m² carbon. All this is embedded in 100% infill PLA+. It feels very stiff.

I do not agree about the Re being totally different in airplanes and wing foils. If you go 15x faster in air, then you have the same Re as in water (same wing chord). And I go 30 km/h on my foil, airplanes with a RG15 airfoil can easily go 300 km/h. AFAIK, differences in Re only matter when the order of magnitude is changed, this is not the case here.

RG-15 is, in some sources mentioned to be 1st choice for F3F model aircraft flight:

F3F model aircraft in dynamic soaring achieve speeds of 900 km/h (for me, this is still hard to believe for a small glider plane, but it’s true).

http://rcspeeds.com/Aircraft?AirplaneType=BD

Note that top speeds are in mph, not km/h.

My wing centre design:

I did not know this software, seems to be interesting ![]()

I use xflr5 when I want to calculate something.

My tool is much more simple, it takes in account the Planform (Surface area, AR, e and thickness) and the conditions (total weight, water temperature, Laminar/Turbulent ) then it gives a drag prediction by interpolating in a database of xflr5 results.

It is for sure not perfectly accurate but it is definitely in the ballpark, I am looking at making it open to the public, we will see when it is available…

Regarding NCRIT, it makes sense, if you have a a lower NCRIT you are basically calculating a turbulent profile (an scratched foil for example)

Here the same comparison where only the Sirus is turbulent:

It depends of which wing we are talking about, the one I repaired, and something like a Xover (low aspect) are just a foamcore and a few layers of carbon/glas, if you go to something with a higher AR, like a Sirus, they have probably a few more layers and a stringer

we are definitely not talking about the same kind of model aircraft ![]() i had in mind something flying 20-30 Km/h…

i had in mind something flying 20-30 Km/h…

I can not comment your structure, but it sounds as it might be strong enough, i thought you just had just the glas/carbon layers.

here he builds 3d printed wings and wraps them in only a few layers of glas and most of them don’t break…