Can you show the motor values you got for the 65161?

Or compare with the ones in this video? You may also follow the whole video for setup to be sure you missed no step.

LINK (About 14:00min)

Yes turned the phase filters of, will try the video from ludwig_bre, thanks for your help so far

Hello guys, working on my free time on an efoil i started some years ago.

My VESC Maytech 200A continous just died from water. I am thinking if i need to buy a more powerful one (but would prefer to buy the same cause it fits my current box design). During my last tests, I take off comfortably at 3250 rpm and i am stable to fly, feeling great!. But afterwards if i don’t reduce rpm, I draw too much current and the VESC heats up to its max in less than 20s.

Reading again the advice of @sat_be , would it help if i have a propeller of lower pitch but same diameter ? (i cannot go bigger than my current 143mm one because the blade would hit the fuselage)

My VESC is cooled down by water flowing up (dynamic pressure) from a mast clamp inlet. Usually I “prepare” the cooling with a hand fuel pump, by pumping the air till water flows out. But I didn’t do it these last times. Could it be the problem/bad cooling?

Do I need bigger VESC but i thought 200A continous was not too bad for my setup (battery voltage is 50V, motor is 200KV) ? (if I had to redesign, I would go for higher battery voltage/lower motor KV to draw less amps)

Thanks in advance!

No, you don’t need a bigger VESC. Your drive system is not well balanced and since it’s the basic hardware that is the issue there isn’t a good solution, only workarounds.

- With the large motor diameter there is increased wetted area which creates drag and requires more power during riding

- With the 200kV motor you will need double the amount of motor current for the same torque. Double current equals 4x the resistive losses in the esc. This is your basic issue for the heating

- Your diy wing might be the second basic issue - if you still use this wing

- 50V x 200 kV is 10krpm. Reaching this rpm requires a huge amount of power with the normal efoil props - but you will not reach it due to lack of torque to drive (the flite prop?) that fast. What it also does is to compress your throttle response. The esc will be requesting high current quickly when you throttle - since in order to lift and get enough torque you need to set max current really high and use higher current by default. You could switch to a lower pitch prop or smaller prop to decrease the load on the esc and lower the heating but I would rather switch motor to solve the basic issue with too high kV.

- The board looks ok, this is not a problem.

- Do you still use a duct? this creates a huge drag and would be one of the easily solved issues

How do you cool the vesc, it doesn’t have a water block as delivered? (Pics please).

I hope you get it running better ![]()

Thanks for your answer @Larsb , lower kv motor would be good but requires money/redesign (mast clamp, motor cables in the mast, connectors) so I could try first a low pitch propeller. So I need to find or 3d print a propeller with 143mm diameter and under 6 inches pitch

No I am not using the duct. Diy wing may not be the best but we simulated its design on Ansys so i would like to first try keeping it

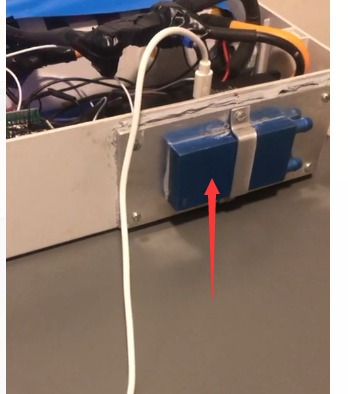

Cooling is done like that:

water flows inside the blue heat sink, with thermal paste underneath and the Vesc is inside the ABS box. (so it’s like a layer Heat sink>ThermalPaste>AluminiumPlate>ThermalPaste>Vesc)

That design is not so good for the thermal resistance so i guess that could also be part of the cooling issue. But i wonder, Maytech brags about their 8 layer pcb (or something like this) but in comparison there is a huge difference in heating for the flipsky Vescs between the normal pcb and the alu PCB variants.

Probably the Maytech VESC thermal transfer is not the best inside the vesc and this would also explain that you don’t feel it being so hot on the outside.

yes it may be bad thermal transfer inside the vesc

you mean “not so good” because there should be a heat sink on both sides of the vesc?

No, because the thermal resistance is set by how many gaps the heat needs to bridge to transfer.

Best case the water block is directly on the mosfets but in the design the path is mosfet-case-plate-block and any uneven surface makes the thermal resistance increase.

If vesc is broken you might as well open the case to check if the inside heat transfer path is good. On many esc:s the heat paste or thermal adhesive is not spread well inside the case.

okay i see, yes i will check

I was also thinking about filling the vesc aluminium case with corrosion X, to add a security against water and to help heat dissipation

Probably not a good idea. I’ve read about vescs dying with corrosion x filling, it might be that it affects the materials, dissolve wires and laquers.

Can confirm, the corrotion x dissosolves the thermal pad between mosfets and aluminium housing. When its gone you get a short between the phases. Boom

Yep CorrosionX eats silicone slowly.

oh okay guys thanks a lot, I will not use it!

Hello guys! I am buying again my VESC Maytech 200A after the previous one died from water (no salt): In Stock 2pcs / 5pcs MTSPF7.12K V2 Max 75V 200A V75/300 based Speed Co – Maytech.cn--Maytech official website.

I would like to try some waterproofing and improving cooling. I would like to have your input ![]()

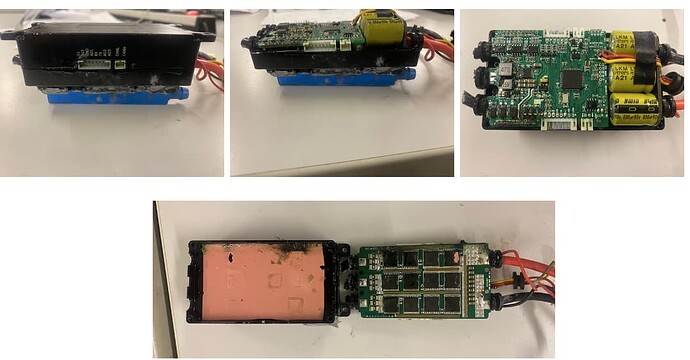

@Larsb following your message about opening Maytech VESC to check heat transfer path, here are some photos step by step to see the thermal adhesive:

. Concerning waterproofing (only for lake use/no salt), i was thinking about using a putty-glue product (“mastic” in french, based on hybrid polymer: Fix ALL Flexi | Soudal)

I wanted to apply putty everywhere water might enter the Maytech casing of the VESC. Photos from left to right:

- pins on the front and back face

- around each cable exiting the maytech casing

- under each screw before screwing them

- at the border between the top and bottom parts of the casing. Hesitating between: applying putty on the border line (outside), or between the two parts and then i close the casing with the screws ?

On the photos, i didn’t put a lot of putty but I would put more if I do it for real. - for the heat dissipation holes, to help heat transfer while waterproofing, i was thinking about something like ePTFE breathable vent membrane (used in the clothes): IP67 Epfte Membrane Waterproof Adhesive Breathable Vent for Lamps - Double Sided Waterproof Breathable Film and High Quality Pricewaterproof Breathable Film

- for the usb-c connector (not on the photos), a simple adhesive, to be able to remove it and put it again easily

What do you think?

. Now concerning VESC cooling, my previous technique was to use thermal paste Noctua NT-H2 (using around 28g in total, quite expensive). Any recommendation about thermal paste choice / how to cover the VESC/heat sink with thermal paste? I read usually it is better a few drops for a CPU, but here it should be adapted to vesc casing. I also read about liquid metal thermal paste, which has better conductivity.

Thanks!!