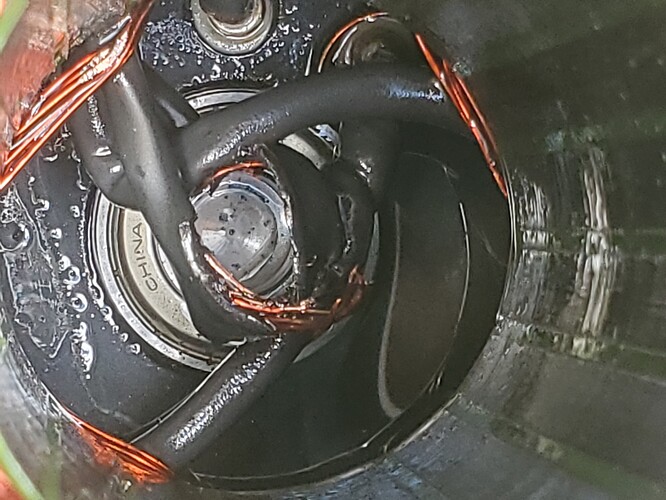

The motor is out of warranty. Can this be repaired? Look like the wires were rubbing on the shaft until the wire housing wore out and caused the motor to short out. Doesn’t seem like a very good design with any protection for the wires.

Yes this can be repaired, the shaft of the rotor can be polished or machined down and sleeved to the same diameter

Wires need to be uncoated ( and some copper coating are pretty hard) , soldered , coated and protected

Now the question is if it is worth doing it ? I guess it is really depending on the skills of the person , the price asking and the room left to work the wires

It is a shame for the rubbing on the wires , doesn’t need much care not to happen

Edit: the thing to do first is to isolate the wires ( tape … ) , cleaning can and shaft , remount the motor to see if it is still running , if the wires have been shorted in the housing : it cannot be repaired and the controller may have being domaged has well , shorted phases happened on my first built : esc ok I just changed the motor

What I’m asking myself, is how it was possible for the wires to wrap around the shaft in the first place? It looks like these cables were too long in your unit.

I just had to open my lift motor recently because the locking ring on the shaft had deformed and caused the rotor to move within the unit.

Fixed it with a stainless steel pipe as a distance holder.

In your motor it looks like the stator loosened up and spun around in the hull. Is that possible?

Either that or his lock ring failed like yours and caught a wire and then pulled them in…

Yes that should not happen at this pricy article. Have you sent the photos to lift. I suppose they should replace it, even if after warranty period, as this is clearly a factory fault…

I got the motor second-hand for salvage parts so it’s not worth too much. Going to clean out the oil and do a quick dirty repair to check the motor as @Alexandre suggested.

I think this is likely the case. The lock ring does look mangled.

Where did you get the steel sleeve? dimension?

The wires are on the side under the coil ( some length is needed) , the rotor probably caught one , twisted it , this one pulled the other two down close to the shaft

I think even there is room to put sleeve needle bearing type so if the wires come again in contact with the shaft it will not be rubbed

So one of the wires is completely severed, and the other two just need insulation or coating but can’t figure out how to open the back of the motor to get access. There is a seam on the back but I don’t see any screws holding it together unless the back is held in by adhesive or the whole back plate unscrew from the housing.

The only way you’ll see a seam if there is one would be to scrape a small section of the anodising off.

When I looked at the FR motor it was a solid unit without a seam.

You can see this seam along the back perimeter. Could be a solid unit and this is just an artifact from machining.

I’m going to say artefact from machining. There’s way too much force to just bond it.

The thickness of the bottom is only ~2mm so it has to be a solid unit to handle the force.

Oh well, it’s a brick for now. Maybe do some surgical repairs with long forceps when I have time after the Flipsky based build is done.

China bearing and questionable wire pulling in 1500€ motor!?, makes me lean more and more towards Flite.

It’s just a 1mm thick stainless steel pipe with 14mm outer diameter and 12mm inner diameter cut to the right length.

I tried fixing the lock ring but once that has bent, it’s practically rubbish.

Did you ever manage to repair this motor? I managed to get a motor like this with the exact same problem.