I thought about it during design phase… did you check if the battery fits the printer area? Maybe get the controller part printed in SLS / PA12, due to the increased forces on it?

I printed it in Bambu PETG-CF, and it’s still holding up well.

@Bzhwindtalker The TPU spacer also works great.

Propeller test mold ongoing, 2/3

There are some defects, the mold should have more piston effect to make it easy to compress the fibers into the desired shape

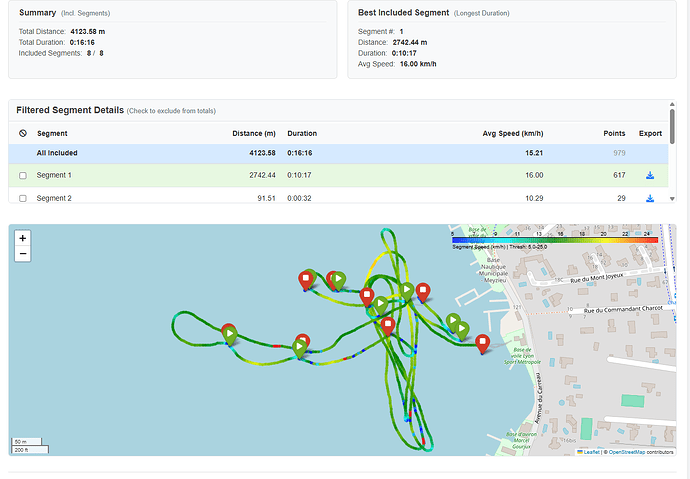

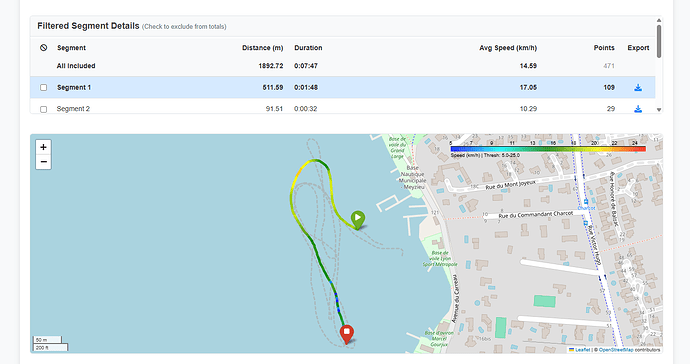

Had a good session today doing up/downwinders in pump, with barracuda XL and small board. Then I tried parawing, had some success and dialed standing up technique, but it was light wind.

There was like 6kt and no swell, so that below must me my longest continuous pump with assist on and no motor.

For small board and PW, grabbing the bar and all A’s on the noze of the board allows to empty any water of the PW and gets the bridles far enougth from the prop to be safe. After finding this technique, standing up and handling the PW is workable.

!

Nice, looking forward to the rest!

Doing the other way around on my end, 12s1p to save weight ![]()

Maybe reducing the wall thickness of the battery part even more would be possible? It is just a mold for the epoxy anyway. So once epoxied the wall thickness of it is not relevant anymore?

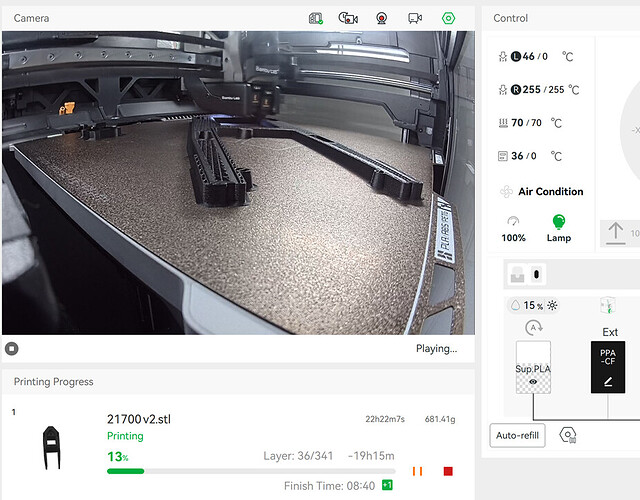

Yesterday I tested 12s3p 15 A/h. I got 35 minutes in e-foil mode on an Armstrong 40L board and a Spitfire 900 wing. I decided for myself: 12s2p is for pumping and riding the waves. 12s3p is an e-foil mode, pumping with such a battery is not very pleasant.

@tkfoil Yes, I agree. I’ll do that for my next battery. Right now, the width is really tight, so reducing the wall thickness would definitely give me a bit more room to work with.

@rttn Aaah nice, 35 minutes isn’t bad at all—especially if you’re swapping between multiple batteries. I can totally imagine that pumping with a 12s3p isn’t very fun. For pumping, I’m planning to stick with my current batteries anyway.

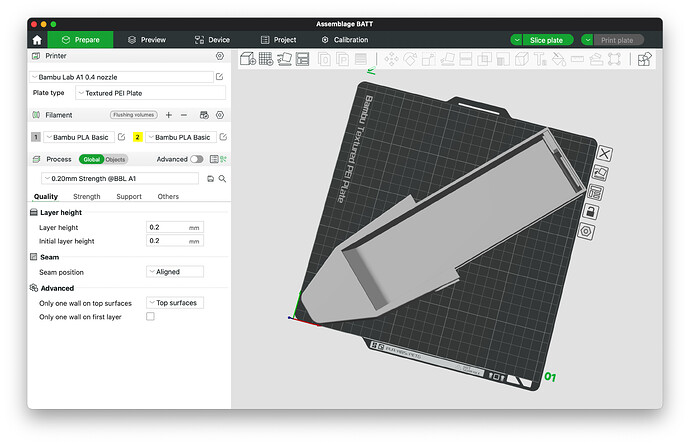

@Bzhwindtalker I’m in the middle of printing the rest now— hopefully it goes smoothly!

That is… impressive if this is 6384 and flycolor150? Can I ask what motor + ESC + propeller this was with? And was cable inside mast or outside?

63100 motor, FC 150, integrated mast

The print has just completed successfully.

For this version, I’m using the Flipsky 75100 Pro VESC because I had one available at home. In this iteration, the MR30 connector can be pre-soldered to the VESC and then inserted from the top of the unit to simplify assembly.

In the image below, you can see the difference that drying filament makes before printing. I dried the PETG-CF used for the base unit, resulting in a flawless finish. The battery box has some surface imperfections.

Whats the total height?

Just 915 grams for the 3d printed parts ![]()

Thats weight, not height. Whats the height of the 21700 version?

Ah, my bad — I read that wrong. The total height comes out to 68.2 mm. I’ve got a little extra space, so I can use wires instead of nickel strips to connect the XT-90 connector.

I was debating between using two or three cells in height. Two would probably be more efficient, my main goal for this version was to make it easy to build a large battery. This configuration made it simple to spot weld a 3P battery.

However, such a height will significantly increase both resistance and lift, and in order to level the board, you will have to apply significantly more effort.

You’re absolutely right—and I appreciate the feedback. If this design doesn’t perform well, I’ll just take it as a learning step and build a new version. Right now, I’m mostly focused on experimenting and improving my skills in modeling, printing, and building.

I like what you did with the inserts and o ring.

A 2p 21700 version would be great for most users! Also nice if it can integrate improvements to make it more reliable.

I think you went mast base plate width on this one?

Edit: seems like before, pespective. But why did you revove the antenna tray if I can ask?