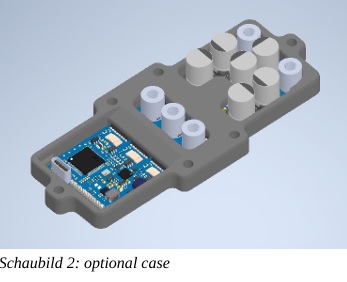

There is one nuance with this controller. The board is curved, and it needs to be screwed to the radiator somehow. There is a photo of an optional case on the site, and, apparently, something similar will have to be modeled.

Small mishapp at the end of a good session ![]()

Parawing + assist, wind was 13kt average and not big gusts.

Went too light on the infill of the pod. It broke in a crash. Just have to replace the part, everything still works fine. My mast and board took some scars ![]()

Fiberglass layup on the broken pod to get back in runing order =

The pod is much more rigid and does not side flex when I apply throttle.

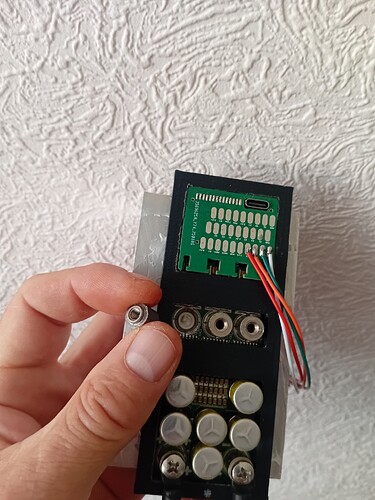

I advise you to be careful when tightening the screws. I can’t say that I applied excessive force, but here is the result.

I can say that European controllers are no less disappointing than Chinese ones. There is no documentation in the kit, no cables. EASYFOIL BWESC V5 - there is no polarity marking on the board, it is impossible to connect via Bluetooth, and adding UUID does not work. And since my questions to the seller about the connection are ignored, I conclude that the problem is in the board. There are traces of soldering and uncleaned flux on the board. In HarryM, the USB plug was broken, and its fragment, stuck in the connector, did not allow the cable to be connected.Perhaps these controllers work fine, but I can not judge this, since problems arise at the connection stage.

Upd. I didn’t even try to tighten the screw, I just pulled it with my fingers… They’re not even soldered!

I tried to take a macro photo and it became obvious to me that the threaded boss was glued, there was an attempt to solder along the outer radius. The glue marks are circled in red at the top right, the soldered contact area is at the bottom. I have never seen anything like this even from the Chinese. How can I fix this?

Looks like the reflow process was not dialed in correctly. Will be hard to fix without a reflow setup/oven

Why not just send back and have the whole PCB replaced by mfg?

I tried to remove the drops with a stationery knife, but it turned out to be flux, not glue. It simply did not solder. The return is too long and complicated for me. I will probably just solder the brass contact pads, and then solder the phase wires to them. In the end, I always trusted soldering more than screw connections.

Yes, I also prefer direct solder more than screw terminals for high current

I also know people who use this exact controller without the screws, with wires directly soldered

Thanks for the heads up, I will check about it when I receive it. I agree that documentation is lackluster…

Hi Bzhwindtalker, please write me a PN since my account is new and i can’t PN you

The controller manufacturer contacted me. The situation was corrected with an old 100-watt soldering iron. I hope for positive emotions from operation.