Today maidenflight after testing of watertightness.

Starting is more challenging as on the 120cm board, once in the air it feels good. I think there will be a lot of fun in 2025 ![]()

awesome builds! what hatch are you using?

Thank You!

It‘s the Osculati round inspection hatch. Size I think is 230mm. It‘s the biggest one.

It‘s 100% watertight. For opening after foiling you Need a Special tool as a lever

What kind of tool? Can you 3d print it?

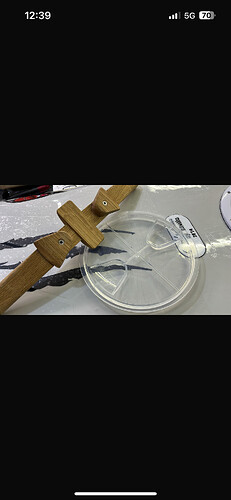

Yes, I have 1 3D printed and one made out of wood

Would you mind sharing the 3d printed tool to open it?

Next time on the PC I can Upload to Thingiverse.

But I prefere the wooden one.

Osculati Hatch by elnillo - Thingiverse

It was qick´n´dirty, not nice, but is woking.

You have to screw it on a wooden stick for example to have a longer lever

Thank you so much!

How did you install the hatch?

Did you epoxy it onto the opening, or did you use marine silicone adhesive?

Did you use the screw holes to secure it to the board? If so, what kind of screws did you use—machine screws with threads or self-tapping screws?

I use Dekaseal 8936 from Dekalin. It stays flexible so I secured the hatch with screws for wood.

Look above threads, there is a wooden box inside the XPS.

I use Sikaflex 291i marine sealant, that stays flexible. I still use screws with nuts inside the box.

How do you seal the screws when they go inside the box, Daniel?

Just put enough sikaflex 291i, it will go theough the screw hole and seal it. A bit of a mess inside the box but it is waterproof. The box of my inflatable is covered with a 6mm carbon sandwhich board and I did not put inserts in the sandwhich, so I had to drill through.

Some fun with new 1m board on 01.05.2025 ![]()

![]()

![]()