here are a couple discussion:

http://www.talkcomposites.com/14490/galvanic-corrosion-between-carbon-fibre-and-aluminium

here are a couple discussion:

http://www.talkcomposites.com/14490/galvanic-corrosion-between-carbon-fibre-and-aluminium

Sleek looking setup mate! Is the blue part printed then painted black p

Thanks, it’s CNC machined in high density polystyrene

I finally found a good way to put some pressure on the fiber inside my tube and get the perfect shape on the wing side:

using a bicycle tube :

Impressive propeller !

Which 3D printer did you use ?

First pic … i would guess: photon? , how long to print this part ?

Very good printing quality, well done

The printer is anycubic photon. I’m really happy with the quality, the only drawbacks are :

Those parts have 0.05mm layers and quality is crazy good ! It took 3 hours for the black part and 4 hours for the green parts. You can print them all on the same build plate in 4 hours (build time depends on height and not of the number of parts).

Strength wise, how does it compare to PLA on a std printer?

Parts are really strong compared to FDM printers. It’s perfect to make thin parts like remote enclosures.

I bought this printer for small parts and watchmaking prototyping purpose :

Currently building a nice full carbon fiber watch

That’s why my efoil build is so slow, too much side projects

That looks amazing! The printers not that expensive, but the build volume is tiny. Whats the cost to print compared to an FDM?

good work,

can you share the link for the propeller?

@Jezza yes got mine for 406€ with 2.25 liters resin on aliexpress shipped from Germany to France in 1 week. 1 Liter (1kg) is 50-60€

@philippe not sure i want to share the file because i copied Flying Rodeo’s idea. I made it myself because i don’t want to spend so much for a propeller

Your next challenge is to copy the Lift folding prop then

I think it’s not a big challenge, just need some dimensions (pitch, height, radius). I imagine the blades are coming out thanks to rotating inertia? or is it a hidden mechanism that push them out ?

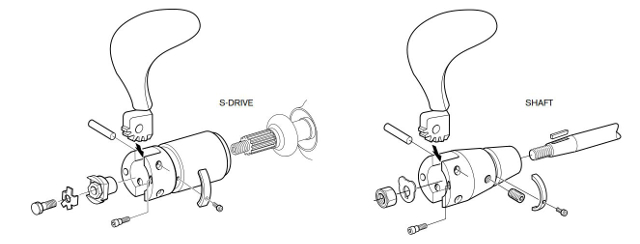

Yeah I would imagine so… Here are a couple of images of others that show some interesting techniques: Boat propeller - S4 - Seahawk - folding / propeller shaft / 2-blade