Hi, I have found a very interesting prop here:

What do you think about that propeller?

Hi, I have found a very interesting prop here:

What do you think about that propeller?

Pretty cool to be able try different pitch at the beach easily. The leading edge would be a weed grabber but I can see how that shape is needed to get the rotation point. Be interesting to see if that guy has it running on an efoil.

Nice to have the two print heads. What other filament are you using?

For supports it is using PLA. It’s on Ext (the white roll)

The PET-CF are on A2 (the red one) and A4 (the black one)

Is the printed prop strong enough? Is your PET-CF better than common PETG for props printing?

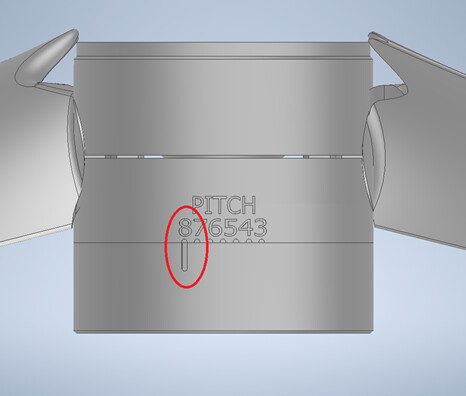

Nice catch. probably needs refinement but amazing: select one of the 6 pitches from 3 to 8 inches, step of 1, and… go. There was a composite commerciel variable pitch prop on sale on the forum circa 2020.

Yes. PET-CF is stronger than normal PETG.

Unfortunately its also more expensive, and harder to print. You will need a hardened nozzle, and obviously your printer will need to be able to handle it.

We have more props printed with PET-CF, and till now no problems.

Still. Aluminium would be the best option.

How is the chosen pitch locked ? Tool-less or not ?

PETG-CF: what is your printer ( w or wo enclosure) and what are your head and bed settings ?

Printer is a Bambulab H2D printer, and the profile used is the one that comes with the Bambulab filament (it’s auto selected by the printer as the info is on a RFID chip within the spool)

Using a 0.4mm hardened nozzles

The pitch is set before you tighten the nut to attach the prop.

Friction should keep things in place.

Hi Kian, What brand PET-CF are you using?

Please share your experience with this prop. I’m going to print it and test soon.

We (my dad and I) are using the Bambulab brand.

See: CF Reinforced PET Filament | Bambu Lab USA Store

Small note: We normally anneal the projects when using PET-CF. This makes it super strong!

more info here: How to anneal your PET CF parts for better performance - UltiMaker

@AlexCyprus I just had ACL reconstruction, so I won’t be able to test for a while.

However, some friends here will test it, and I’ll report back as soon as I have more info.

I have printed it with PLA. Seems blades are too thin and weak. Unfortunately my experience in 3d modelling doesn’t allow me to change the blades thickness.

This is the modified 3 blade version.

(Still needs some sanding)

Printing an extra thick blade now. When okay I’ll post it here.

That looks pretty nice as a 3 blade. Clever cad work on your part.

What could be interesting is sticking a Fliteboard blade from a step-format scan to a threaded stub of this multi pitch prop… Best of both worlds, just thinking …

I printed this in Bambu PLA-CF and would share the following opinion since you asked.

Interesting design - likely a lot of work to create and way beyond my CAD skills. Also might be fun to try different pitches but with two blades that appear to be more flexible than the benchmark Flite prop I have doubts about any performance improvement over it. Perhaps the 3 blade version that @Kian is working on might do better.

I would also point out a few things that might be of concern.

the large cutouts don’t seem to have a purpose other than a tiny reduction in weight and might be a point of failure - compared to a more solid “disc”.

the area where the shaft pin goes isn’t very big limited by the cutouts driving the need for a shorter pin.

the rotation to change pitch isn’t very “smooth”. That could well be my printing skills or the material I chose.

the blades I printed have a substantial flex compared to the Flite prop so need to be either thicker or printed with material stiffer than PLA-CF.

See photos below

Not too surprised by this. Have you printed any other props with your PLA-CF? I think another point of comparison would be this multi-pitch design and a traditional blade design printed from the same material.