If memory serves, I read on a thread that another member was struggling to get the full power out of his motor with VESC. After some checks, it looked like this was because of the phase/motor current being limited. I remember reading the CLI command to fix it.

Thx guys.

I think @Alexandre is right. My ERPM was probably set too low. What’s the max RPM on this motor? If a safe max is 10,000 RPM the for a 6 pole motor, that’s 3 pole pairs, so 10,000 x 3 = 30,000 ERPM setting.

If I set my ERPM to 5000, then that was limiting my motor to 1,666 RPM.

Sounds like @Alexandre just sets a really high value for this settings to make sure it doesn’t limit the motor.

These VESCs have a lot of settings. And there is no user guide. That’s crazy. How has no one come up with an all inclusive user guide by now!?

VESCs allow a Bluetooth connection. They give you telemetry.

They can interact with other things like a BMS and give you individual cell voltage, motor current, amps used, temperature of VESC or motor, and you can record the data.

This is very helpful for tuning a setup. Different props, motors, batteries… Things like that.

The ERPM limit is not to secure the motor, it is to secure the ESC. To high ERPM can blow up the ESC.

Old 4.12 VESC hardware was good up to 60kERPM. The new ones are tested to over 120kERPM.

For ESK8 you can also limit the ERPM to have a speedlimit.

But for propeller use you got anything from 100% (static thrust test) to -100% (being towed) slip, so it doesnt make that much sense to limit the ERPM below ESC safe range.

So none of us should run the motor with 25 degrees with flier esc?

Yes. I think 25° timing is too much for this motor. Other users say they think around 10° is correct. But, I don’t know the correct value.

However the firmware Flier has made for this motor that I’m using works really well. I have rode the board twice now. For about an hour each time. The motor ran cool. Nice and smooth throttle. And plenty of power. This firmware is the “BuArtLowKvMotor” firmware. And the settings are not adjustable. So you don’t have to worry about setting the timing wrong.

I don’t know what timing value Flier has set, but it works good. I guess you could email them and ask.

Thank you for clarifying this.

Anyone else trouble open up the motor?

Screws are out. I try to open it with something Sharp and hit it. Motor looks stuck

Yes and no , the way I see it : limiting the erpm limits the rpm , most prop needs high amp on start for torque but as the bord starts to move , torque is lower .

Then it goes up again as we need speed

So limiting erpm , limits rpm , limits torque is a way so amp but my point is that there is a lot a setting with vesc so no needing to bother with that kind of limit

On my 75/300 , I changed one setting at the time , see what it does but most of limits were left high

50-60 000 should be fine for most setting on Efoil

I am just starting to learn about vesc , so be kind , I come from petrol race engine …as far as mapping ecu

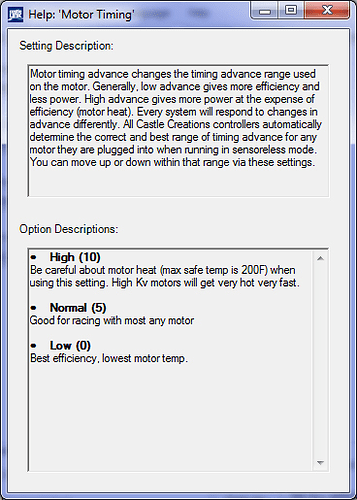

The timing , I might be wrong but the way I see timing , is as a way to apply delay to let things happen , small inrunner , low rpm , no need for increasing timing , 10 degrees for a geared 56mm spinning fast , may be … or 30 for a large outrunner spins « fast » with low kv and big prop …

Correct me if I am wrong but timing set at 10 meens -10 degree in the revolution period so physically setting things before to allow more time , as rpm increase timing needs to increase … max rpm for a classic 56mm inrunner is 50 000 , so 6000 this is not that much , if rpm drop on load is not high no need for high timing and it is not the best way any way ( bigger motor or small prop …)

They are using Loctite to hold the screws which also sticks the two parts together. You may need to briefly heat the uper part to get it out. Also, put one screw (or even several) on the inner diameter ones to get a leverage point to be able to pull it out.

Not exactly. The timing angle is the angle shift between the slots and the poles (rotor for an inrunner). This means, this is the angle when the polarity is detected and shifted on the stator.

For exemple, I am pretty sure FR’s motor have a timing of 0-1°. My motor is simulated to have a best efficiency at 0° timing too. This depends on the slots / poles configuration. In my case, modifying the timing have a huge impact on the efficiency (like 1% at least, which is already big).

I see so each motor has physically a offset ?

What I meant since a motor is in rotation the point ( shifting between magnet ) needs to be anticipated by adjustable timing in order to occur at the 0-1 degree , because current doesn’t flow right away , no ?

dynamic « timing » no ? That is why 80100 gets out synchro when load slows down to much rpm because of the open loop drive ?

One rpm at one load = one timing to get best torque without to much heat ?

Time to explain something about timing.

Timing has relatively little to do with time.

Think of it as a spark advance similar to a gasoline engine.

It doesn’t matter whether you are an inrunner or an outrunner.

It depends on the mechanical structure. A high number of slots with a high number of poles can run very effectively even with small timing, if the angular misalignment was kept very small during mechanical construction.

It can also be the case that a 4 or 6 pole inner rotor with a 9 or 12 usable number needs a large timing because the rotor has been kept very small in diameter.

Greetings Frank

Tuning gasoline engine: I use first a formula that gives me the speed of flame propagation and so time (ms) needed ( rpm afr engine …) between spark and full combustion

Then test on road , fine tuning advanced timing on load and checking arf exhaust heat and knock

Increase advanced timing let the spark occurs before the top piston position so it lets TIME for the combustion to take place and the piston is at the right place to get pushed down , not to early not to late

Even if the engine has a offset timing at rest , timing is needing in dynamic to compensate « inertie »

Take a look at these :

I too am not a specialist in this domain. Just trying to understand ![]()

http://site.petitrc.com/Tech/RCCA_MotorTimingExplained/

In geneal however :

I played some more today withe flier firmware.

The B_Uart_LowKvmotor is ok but starts 8 out 10 times, 2 times per 10 is a misfire, it just beeps a bit and does not find the right timing, turn the motorshaft a bit and it will start.

At lower rpm you can hear timing is not very good, full throttle sounds better, I’m not an expert but I think you can hear by the sound how smooth the timing is.

Boat 24s_V32A works really good, starts 10 out of 10, and the motor runs more silent, also completly free from vibrating at high rpm at full throtte. Better than the B-Uart, lowkvmotor.

But it starts really really hard, I think it will break my mount soon. It alomost destroyed the prop, it wear out the pin in the prop that goes in the shaft. The motor start with a loud BANG.

So it can be done by flier I think.

You type of remote are you using in this test? The maytech remote? Did you calibrate the throttle?

I had some starting issues when I was using a cheap electric skateboard remote. Calibrating the throttle fixed the problem for me.

I had the best start function on the BUartLowKVmotor firmware. But, I’m using 14s battery. So maybe that why my results are different. I don’t know.

If you using a firmware besides the BUartLowKVmotor firmware you can edit the settings. So, you should be able to fix that hard starting issue you’re having by adjusting the “start power” setting. And check your timing settings. Sounds like most people think this motor should run between 0 and 10 on the timing.

Yes I forgot to tell. I tried all settings but the hard start did not change and yes 5 deg timing runs best. I run 11s and 100kv motor. Maybe 100kv is even harder to start.

I just checked and no load current is lower at buart low kv. So that is good.

I use the waterproof 40usd eskate remote