I had quite a hard time finding thermally conductive epoxy adhesive. There is a lot of gel, paste and grease, but not adhesive. I eventually found and used Electrolube TBS (TBS Thermal Bonding System), so far no issues but I don’t think I’ll be able to remove my ESC from the cooling plate easily.

With thermal paste I would have to find a way to hold the ESC against the heat sink with some kind of mounting bracket, and I couldn’t think of a clever way of doing that. Thermal adhesive is probably a better option, but I was not sure if my heat sink setup would work well and I wanted to have the option to easily swap to something else if needed. The tape seemed to be a good option for that. I am using a modified heat sink I found in my random parts bin, I think it’s from an xbox 360.

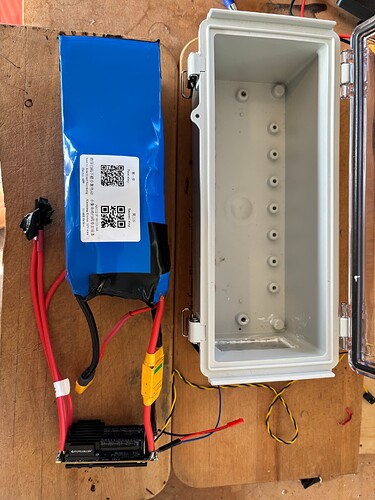

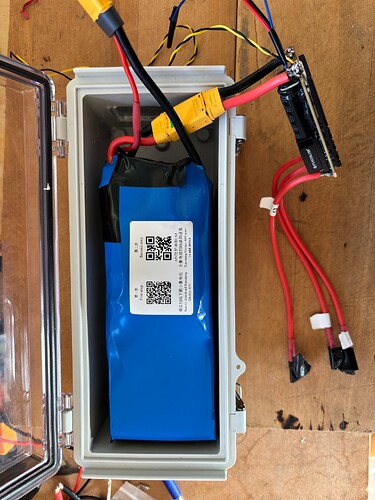

An update, we built the battery and I tested the circuit which all works.

Unfortunately the battery doesn’t easily fit in the box with the ESC as I didn’t quite get the cable orientations and dimensions right. Also made a mistake with the BMS wiring so need to open it back up again.

Since I have to partially re-wire the BMS leads to one of the cells, I’m considering removing the BMS and XT60 charge cable from the battery, and instead wiring the BMS into the charger lead, and using the single XT90 to charge and discharge.

This would require some re-soldering of the positive and negative terminals of the battery which I’m hesitant to do, but definitely would create a lot more space and would let me re-orient the connector cable in a more favourable location.

I’ve also got a small external aluminium box which I can attach to the end to put the ESC which adds a bit of extra space, which is my backup plan.

@oldmate Would you mind sharing the specs of your battery pack, and where you got the box? I am waiting for my spot welder to arrive. Planning to start with a 11s2p or 3p. I just started with my built and trying to find all the bits and pieces. Sometimes not easy here in New Zealand ![]()

Cheers from Mount Maunganui

Hi,

I’ve not had much luck with the BEC you list on your initial posts.

I’ve blown 2 of them on a 12s pack and finally ended using a different one.

Let me know if this works for you as I’m curious if I had a bad batch or is actually not linking the 12s.

Cheers,

Jordi

Hey @cube it’s a Camdenboss

My battery is a 12s2p made up of p42a molicel cells, laid out in a 3x8 pattern using a design from elsewhere in the forum.

There’s a crew in the mount who have built a bunch of these and seem to have the setup dialed. They go for 10s3p builds, and put the esc in an external box on the end. You should hit up @marcoz to see how they do it.

Thanks for your feedback. Very much appreciated!

@marcoz Hey mate. Another newbie here and also located at the mount. Would you mind coming along next time you are going out and have a closer look to your DIY?

Hi @oldmate, I’m planning on building a very similar setup also in NZ. What width and thickness nickel strips did you use in your battery?

The wind has stopped until spring so looking for a new project. How much have you guys spent so far on the gear for your builds? Also in Sth Island

How did you choose to connect your phase wires to the motor in the end?

Just ended up soldering them on. Getting a higher power soldering iron makes all the difference.

I reckon $1500ish is a reasonable estimate, more if you have to buy tools, soldering iron, spot welder, 3D printer etc.

Right so an update for anyone interested - I lost the box part of my original build overboard after only 3 sessions, the dual lock was not good enough on its own to secure it. Seems like a few others in this forum have hade the same situation, or had the latches come undone, so heed my warning and have two ways of securing your setup!

I’ve since built a new box and a 10s3p battery comprising Samsung 50S cells, and using the smaller bud box but with an additional external aluminum box to house the ESC.

I’ve had one session with the new setup, it was a bit underpowered to get me on foil consistently, but I think there is a combination of bad technique, the motor pod being too high, too small front foil (ART v2 939) and ESC config settings.

I had current limiting set at 50 amps, based on what I had read elsewhere in the forum but I think I might turn it off. I was wondering if anyone here has recommended settings for the Flycolor HV3 160A ESC with this type of battery setup.

Also, went to use it the next day and my Flipsky VX3 remote shorted out on power up so I’ll need to replace that before I can get back on the water. I was expecting the things that I build to break or fail but I’m disappointed that a so-called waterproof remote died so early into its usage.

Current is too low. 60A was good for me on the 939 at 70kg but 80A will be easier and is what I’m running (and most guys in Tauranga with these setups). I managed to get the Art 699 up with a 3"10 board using the 80A setting ![]() so you’ll be sorted with your setup. Some guys here have turned current limit off and seem to be running fine too.

so you’ll be sorted with your setup. Some guys here have turned current limit off and seem to be running fine too.

Cheers I’ve updated the settings.

Flipsky is sending me a new remote so will hopefully be back on the water soon.

Any tips on separating the stator?

Have removed the circlip, and been trying to use the hangloose rotor puller but I can’t get it past 10mm. I think ill need a 150mm bolt to push all the way if it doesnt want to come loose.

This is the first time ive tried to fully pull it apart, still has the original ceramic bearings.

I realise I should have done this earlier, its been in the sea about 6 times but rinsed in fresh water after each use.

The first time you pull the rotor off, it’s always difficult.

Try a longer screw and some oil on the shaft.

I always sand my shafts a bit with 800-grit sandpaper.

When I put the rotor back on, I always apply grease to the shaft. Then, the next time you pull it off, you won’t need a puller and can do it by hand.

Your ceramic bearings might also be causing problems on the shaft.

And then buy stainless steel bearings ![]()

@Hangloose that is good advice about sanding shafts. You might find the two ceramic bearings come out with the can.

Baz : Miniature bearings in Christchurch have the bearings.

Take the Can when not using spray bit of corrosion x on bearings after washed and dry.

Since I use sealed stainless steel bearings, oiling the bearings doesn’t help.

Besides, I mostly ride in freshwater.