You beat me , with my swordfish 300 , brand new leasted 20s, feel sorry … but did you manage to change the resistors yourself ? Using a heat gun ?

I used small soldering iron. I was lucky because I got this faulty one replaced, so this was a left over. I thought I may can fix it…well apparently this is not the case

Well you tried and learned , best value for me even if something the end is happier ( the way I try to see things even if I believe 1/2 of it )

Always wanted to try soldering with a gun and paste

Yesterday I tried the opposite : solder 1mm copper busbar with a blow torch …

This resistor story is a shame …

If you have fingers like sausages, you shouldnt solder smd resistors.

They may be not as thick as sausage but for sure similar greasy

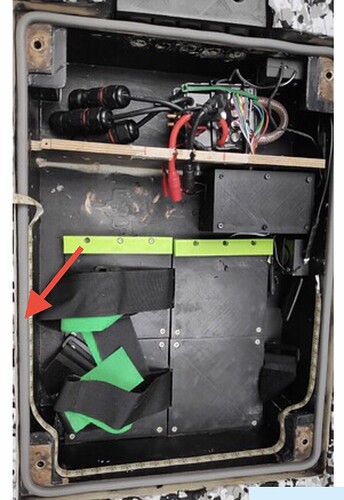

Awesome build, congrats ! A lot of interesting ans simple solutions. Where did you get the rubber seal (red arrow),

how you glued it and what is the thickness of the plywood hatch ?

hey mate, what tube are you using ? I’m going for active cooling with a hole in the nose and searching for the adequate tube & size

The famous @Toto44 seal. It should be in my bom list or you can go for here:

https://www.amazon.de/dp/B07VX69WNC/ref=cm_sw_r_apan_glt_i_JRBMN1H7QXJMNPRYARHT?_encoding=UTF8&psc=1

Sry I forgot. It’s double sided taped already. So I did not use additional adhesive. Plywood is around 1cm I think. Should be mentioned somewhere in my build

Well I have no tube in the mast. From mast plate I can measure if you want, I really can’t remember. The hole in front mast clamp is quite big, I think it could be smaller

Thx Jan, just ordered some joint from Amz.fr. I missed it in the list, sorry.I received the water alarm you proposed. What a crazy noise ![]() it will make me more confident as a tiny amount of water can be detected. Did you glue the joint directly to the Plywood?

it will make me more confident as a tiny amount of water can be detected. Did you glue the joint directly to the Plywood?

It’s just wobbling around at the bottom. But I taped it also once. So do whatever you like, but it makes sense to fix it

Hi Jan, Thanks for you reply  Did you apply the adhesive silicon joint directly to the wood without any paint or resin applied to the wood? No water ingress so far ? One last question, did you glued together the two ends of silicon joint to avoir water penetrating in between

Did you apply the adhesive silicon joint directly to the wood without any paint or resin applied to the wood? No water ingress so far ? One last question, did you glued together the two ends of silicon joint to avoir water penetrating in between

No, I grinded the plywood walls a bit by hand and then took a brush and applied a film of epoxy on it to close the “open plywood structure” / Cutted edge.

Got it! This what I was thinking to do. Il will impregnate the wood-box with resin and ketone solvent and will finish with pure résine.

Just received the silicone joint from Amazon. I a worry a little about the 90 degre angles in the corners of the box…but apparently no issues with your two builds.

On some pictures you have a transparent hatch , is it rigid enough?

Just don’t go 90° with the seal. I have added some additional material in the corner so you don’t need to bend too had, just look for a picture in here.

The top cover is plexiglass, it’s about 1cm thick and pretty rigid. It’s not very light weight though, but the advantage is your able to look through on the first rides to get confident that it works. Later I put grip tape on it

It’s been a while. New pizza foiler has entered to the scene (not on Forum)

Thanks @kotnascher for that awesome drone footage

Hello.

Sorry for asking question on this old post…

I got myself same silicon seal for my hatch and im curious how did you connect two ends of seal?

Just cut a mm longer than needed and squeeze in. Very basic but working for me