Hello everyone!

First things first: thank you soooo much for your contribution to this amazing community. I’ve been reading this forum for ages and each line written in here gave me so much inspiration to switch my tv and go for it: build an e-foil.

Like many of you I was also someone who once saw a random video on a gopro comercial or something of whoever e-foiling. Gobsmacked by that weird/magic surfing style, started to google that shit to find out how realistic it was to purchase one of those. For my surprise, retail prices abroad as we all know starts around 5000 euros (that means twice that much in Brazil due to the extortionate import duties down here, 100% on top of purchase price or even more). Conclusion, nooo way.

Fortunately google brought me here. I’m a DIY guy myself and after reading loads of info in here, plus watched countless videos on youtube, learning about (con)fusion360, 3d printing, vesc setup, battery packs, etc, started to come up with my own setup, that being:

Electronics

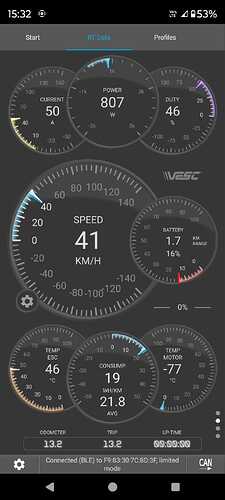

*Flipsky 65161, 120 kv motor

*Flipsky FSESC 75300 Speed controler

*Flite propeller

*12s9p recycled laptop batteries (on a citycoco scooter battery box) with ANT BMS for charging only, installed externally (less weight on total setup)

Flipsky VX3 remote

Hydrofoil:

Cheap Aztron Rocket 2000

Board:

Well, that was the most painful part, here we go:

Could not care about making my own board. This is something I really run from, just can’t stand that messy resin job, plus, sanding, then glazing, then sanding, then painting, then sanding again, then varnish, more sanding ![]() , well, you get the ideia.

, well, you get the ideia.

As I live in a place where there’s a shaping workshop on every corner, took advantage of that and outsourced the job. My choice was a local maker @skingbrasil . Costed me around 1000USD plus 250 USD for the hatch installed. Delivery time was 45 days, full payment taken upfront.

For my misfortune, this shaper (his name is Mauricio Cunha, beware!) was slow as a snail. Took him 6 months to finish my project. Nevermind, I’m patient so, move on.

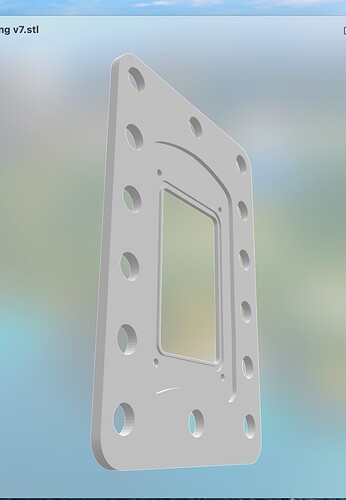

Board was allright, but he scammed me on the hatch part. I was promised a hatch with rubber seal, hinges and a quick latching system, like the comercial models (he even send me some sample pictures and confidently told me he could deliver something like the ones in takuma efoils). Once received and I unpacked the board the big disappointment: there was just a hole in the board and a wood cover, no hinges or latches.

Anyways, would not bother arguing or risk return the board and got another 6 months delay. so sorted the issue myself : installed some inserts, a rubber seal and bolted the cover to the board. Not ideal, actually a pain in the ass to remove/reinstall the battery for charging everytime, but hey ho.

First test successfully documented here:

Shortly after this take the big push and I had the lift off, which I can’t share with you guys unfortunately: Had a deep nosedive after which broke the camera bracket and at this moment my insta360 is around 4 meters deep, unrecoverable ![]()

Still had some passers by filming on their mobile phone, so managed to get a screenshot to prove: it flies! (first time using this forum, so not sure if I’m attaching pictures right)

Well, that’s all for now. I’m happy to answers questions details and contribute to this awesome community!

Best regards from Florianópolis, Brazil ![]()