good job mate! your pack is BEAST!

could you share more about the ESC to mast cooling?

Is your mast removable from the board (to carry it)? wondering how you get it water tight

is 75mm enough for eFoiling?

good job mate! your pack is BEAST!

could you share more about the ESC to mast cooling?

Is your mast removable from the board (to carry it)? wondering how you get it water tight

is 75mm enough for eFoiling?

Huge pack cim96dm7. Did you put some fishpaper or similar under the balance leads, so that they can’t rub through and short on another row of cells?

These are all great decisions - the placement of the motor as a Flite and the high battery cell count. I’m following a similar approach (though unfortunately much slower), as I see this as the only way to get the best core parameters in the world, compared to any current e-foil solution. It will be possible to increase these parameters further, especially with the use of future wings and propellers.

Ah, the first entry into the solo round the world efoil race

No its an old battery from my esurfing days with good old 18650 25R’s Hence 15S, since MGM controllers can only do 63v. Its just been laying around 2Y now, so i wanted to put it to good use.

I hope to get 35km’s from it so that i can bring the distance cup back from Austria.

hey fam,

I was hesitating a lot as I know it requires patience and although I’m getting older, I have more patience, but less time for DIY ! So yes, I pulled the trigger on the very first part… the motor : a flip sky 65151 120kv

I’ll start by getting the mast/foil done as a complete part.

So now guys, I know many of your go for the Gong, which can be a good entry foil for a cheap cost but I may not be building multiple foils, so I want to get if possible a good one, even at a more expensive cost. I’ve seen the ozone used by Tibo @Manufoil - full carbon but drilling through the mast is going to be a challenge whereas on an aluminium mast, this should be a piece of cake. Last but not least, which mast length would you recommend at minimum ?

Can’t wait to start the project!

The inside of the carbon gong poles is made of Airex so it is easy to drill for the cable routing . @jeffM has done the experiment for this pole. As for the size of the mast 65/70 is good for lakes and river bigger is good for the sea and passing waves.

On my first one I’m in 65 and on the second one in 85 : I like the 85 the sensations are better and the engine comes out of the water less often .

Hey Cedric !

Nice to see you here.

I’ve vbuilt 2x boards : one from an old windsurf board, for beginners, one from scratch, a copy of the Fliteboard pro board.

For both boards, I used :

From my perspective, making an efoil takes A LOT of time. Much more than an esk8.

The most time is spent on the board and hatch/waterproofing tests.

If somebody makes the board for you, then you save a lot of time.

Regarding money: cheapest way : 2500€

If you modify a Gong wingfoil board and find somebody to make a nice hatch and inner box for electronics + battery, I would say 3500€.

If you do not have the time, PWR foil is definitely the way to go: the board is awesome.

One thing to consider though: motor is the same as Flipsky, and remote is from Maytech. The feeling will be the same as most DIY boards.

So now the question is : is your time worth the 2500€ difference ? =)

Hey Thom ! super cool. Thanks for the greetings.

3000 is a lot of money to save and I believe I’ll be able to easily make the battery, electronics. My challenge and you pointed it right, is the board and waterproof ability and the time. I’m not that much afraid with the composites (especially because I did a bit of that in ESK8), which will be reduced to the minimum (I don’t even need to use a vacuum bag or pump if I go for a Gong Board). I could lay the fiber over the epoxy and call it a day. For the hatch, I could also do it like that

For the board, I could buy a Gong Kube 4.2 (899 euros) wing foil board and the Foil as well and dig into it. Then my only challenge will be to dig, and make the hatch waterproof but also dig into the mast (which I don’t know how I can do it).

6500 is too much for me to pay (I don’t have that money) in my actual life although I’m sure that the PWR is awesome, so building it and saving 3000 is still my pick.

I’m doing kitefoil, wing foil so if I can get a better foil than a Gong, I can also pick that option, on the riding side I would consider myself a bit more advances that if I was learning. I could use my wingfoil foil, but it’s an AFS and full carbon (and ultra expensive)

Ultimately replicating that board

ps: I already spent 300 euros on the Flipsky… order done. I’m trapped !

Tehn the Gong -style efoil is a good idea !

For the mast, I don’t really see the point in having a carbon mast. It’s stiffer for sure, but gong launched a new stiffer alu mast few month ago. Takoon copied axis with a High Aspect ratio foil and stiff alu mast.

For the waterproofness, I asked a shaper to make the hatch for both boards.

He used carbon fiber over Airex 70kg/m3. Put the carbon fipber on glass so that it’s super flat and smooth + vaccum so that everything is properly glued with epoxy.

For the cavity inside the board, I designed it in 3D and 3D printed everything. It is therefore quite accurate in terms of dimensions and pretty stiff for the weight thanks to the 20% infill.

Also, my boards are quite reliable regarding water because everything inside is also waterproof : electronic box IP68 for VESC + Battery box IP67 filled with electronic Gel so that even if the is water inside the boxthere is no risk for the battery.

The dual waterproofing is the way to go in my opinion, it gives you peac of mind.

This one is 959 euros but I’m wondering if it’s a good idea knowing I could use the wings on my wing foil

I also got a 3D printer so that’s not going to be a problem to get the box printed in multiple parts (and that will correct my poor drilling capabilities

Is it really different from the one sold on Decathlon ?

yes, it’s a helium foil and known as an awesome wing foil foil

Look on the bon coin you have a lot of gong equipment for sale.

Has anyone used this?

this is now getting serious!

I also ordered the polymaker ASA filament and also going to make an enclosure for my CR10 printer to get a good temperature around the printer (I got the printer in my garage) and limiting any printing challenges that can come my way.

I’m now looking to get an AFS carbon mast (this is expensive but I already got my wings HA, etc… from my wingfoil) and AFS guys are just great people!

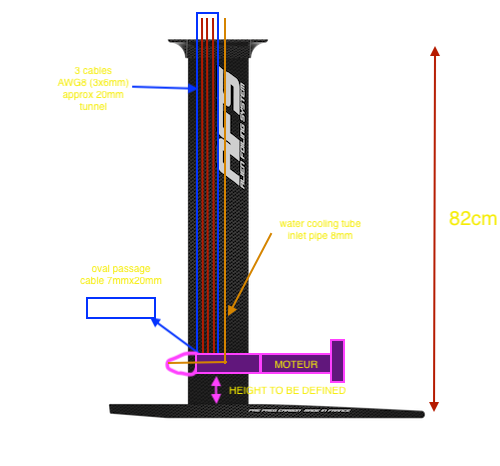

I’ve started the drawing of what this will look like but I would like your confirmation and insights.

Plan is to channel the 3 motors wires 6mm thickness + the water cooling tube in the mast. Would you suggest having a 3x6=18mm… so let’s round at 20mm … and lets add 8mm tube… to get a 28mm x 8mm hole in the mast and on the side of the mast (inside the motor attachement adapter) ? Should I go for 20mm x 7mm to channel the motors wires and… close to this… a 9x9mm hole for the tubing that goes to up to the top of the mast ?

last, does anyone can share the STEP file so I can make the adapter for this mast and also add the water inlet on the nose ? I will of course share it widely with the community when I’m done !

Salut OKP, good to see that you have a thread for your build. You are ahead of me. I will follow your progress with a great attention. I just received my ESC , the Motor and the remote are on their ways. I already have a F-one foil from and two masts from my wingfoil. Bad surprise the mast is full of elastomer and plugged with epoxy, but after removing all this stuff there is plenty of space in it.

No worry I will not bother you on your thread just will watch to follow your progress and learn from you

Enjoy your build!

Hey mate, check with the AFS guys they don’t use woodcre, it would be super tricky to drill, near impossible… If it is high denstiy PVC it can be done but it is tricky, you are taking quite a risk on an expensive mast. If you really want a carbon mast the easiest would be to find one with an EPS or XPS core, not sure if there is any on the market. With EPS or XPS you just have to drill the baseplate and pour some acetone in there, it will fully disolve the core.

Get one of these if you go ahead. https://www.aliexpress.com/item/1005003372144011.html?spm=a2g0s.imconversation.0.0.64413e5fESXmqL