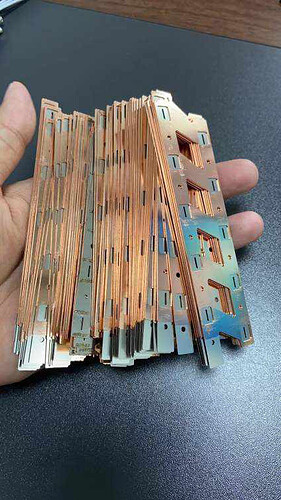

This is a different variation on the copper/nickel sandwich, where the objective is to use nickel as a means to weld copper battery connections to facilitate higher loads.

I’ve been able to get good welds by using a circular punch on 2P .2mm copper strips sitting under 2P .2mm nickel strips. The circular punch allows direct contact between the nickel and battery terminal and once welded seems to provide a good amount of surface contact between the two metals.

Any reason this would be a bad idea?

I initially came up with this idea after incorrectly thinking .2mm nickel wouldn’t stand up to 100amps, having seen the nickel strip calculator that appears to not actually be the case.

Regardless, this seems to be a potentially novel way to get higher load connections.