thanks, i saw that befor i printed it but i thought it should be this way…

yea good thinking, maybe a disc at the back of the motor with the wires coming out on one side, sealed with silicone within the tube,

@pacificmeister do you happen to have the exact specs/order no for the Neugart 5:1 gear because the US vendor is asking me too many questions on what motor measures and what not

Much grateful for your efforts!

if you go in to neugarts web page, its all there id say, look for the Ple 40 or the Ple 60 gearboxes

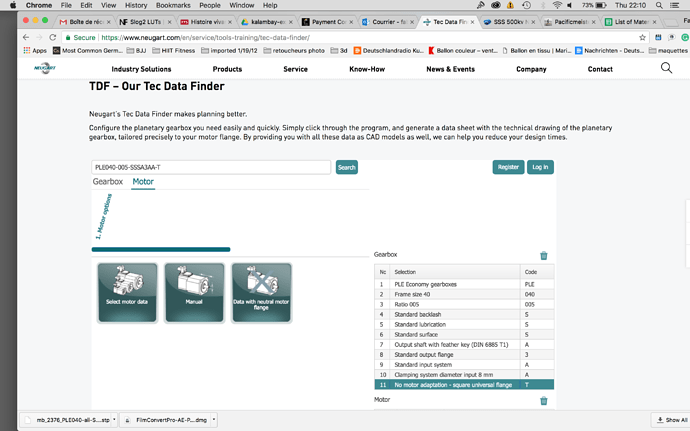

I had exactly the same problem, using the setup wizard from Neugart here https://www.neugart.com/en/service/tools-training/tec-data-finder/ I made the configuration that I think is the right one, see attached image.

So maybe @pacificmeister you could validate this configuration so that’s fixed for everybody?

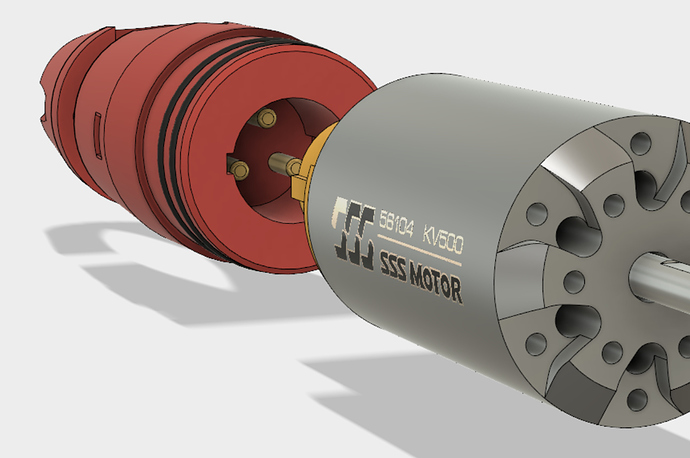

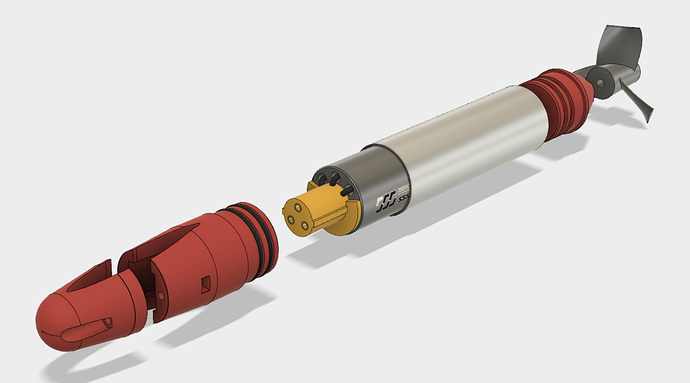

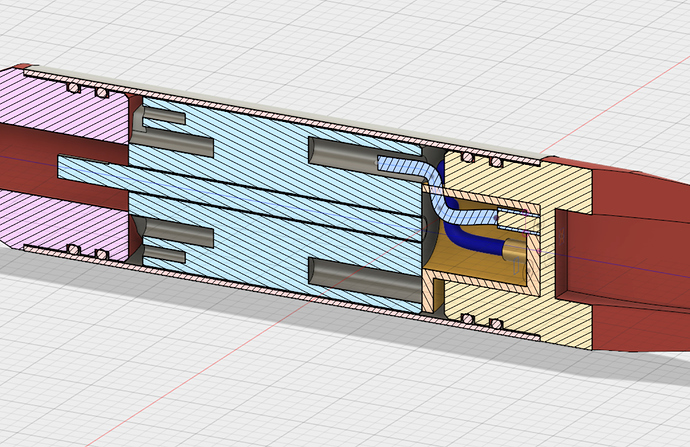

@rfinkel, @keith75 - In case you want to look into a plugging system for the motor pod below, here are some of my thoughts from earlier this summer. I never built and tried it. Not much room there and it will be a challenge to connect cables and epoxy the plugs in. But it might be nice to have double O-rings on the mast side too and be able to just pull the motor out. Here the Fusion file if anyone is interested to mess with it :), …one of my direct drive test assemblies … and here a few screen grabs. The yellow part would be mounted on the SSS:

Yes, that’s exactly the Neugart spec of my gearbox. They have such an amazing web configuration tool but I found no way to save and export the config to communicate to their sales team. Either I missed it or they like to deal with screen shots

@pacificmeister if using the slower SSS 56114 360KV motor and your duct/prop setup do you think the 5:1 or 4:1 ratio gearbox would be better?

Pacificmeister,

Just printed the Duct assy and see you have 2 small holes, Are these to lock the thread of the duct? If yes what did you use?

I’d go 4:1. What’s your plan to attach the 10mm shaft to the gearbox?

Yes I put little M3 set screws in to lock it

One last thing,

With the props…what was the issues with the 4 blade and other props i see on the cad source.

Was the 4 blade too hard for the motor to turn…need more torque

The 2 blade how was that?

You seem to be happy with 3 blade 120mm diameter one.

Am i right is saying if i heavier than you i might have to go to smaller diameter ?

Just different tests. I didn’t try that 2 blade yet. Both 4 and 3 work fine. Didn’t feel much difference. Need to start recording data to make better decisions :). There is a good post about prop parameters here somewhere and the effect of blade count.

Ye i have read the post but all very complicated to me ref the motor speeds and torque, prop pitch and diameters. Cheers for the info looking to do some test in a couple months, still building at mo.

Thanks! that was my inclination too – it’s the last part I need

I have a metal lathe so was planning to turn down the motor shaft to fit the gearbox directly.

Cool. Curious how you do that with the lathe. I was thinking about powering up the motor and holding a file to the shaft until it’s at 8mm. Worried that it won’t be 100% centered, especially since it has that keyed shaft and my file will bounce around… so I need some rigid setup to hold my tool steady.

I had two ideas: disassemble the motor so I can hold the shaft in the chuck with spindle steady rest at the other end (after carefully covering the magnets) or hold the body of the SSS motor in the chuck to center it and lock the lathe spindle. Then fire up the SSS motor and use the lathe tool to machine the normal manner. BTW I saw a post from someone in SF that offered his garage machine shop services shortly after you created this forum…

Thinking out loud … I wonder if you made a little wooden jig to hold the spinning SSS motor firmly and used little grinder (e.g. Dremel) to machine the bulk of the shaft, using the file, held tight against the jig for the final finish.

Final idea: could the gearbox pinch clamp be machined out to 10mm without compromising it?

Edit: @pacificmeister I realize you live in LA … sorry I was thinking SF given one of your videos…

It was a pretty easy job to pull out the rotor and turn it down. Maybe you could find a friendly local machine shop to do it for you.

What if ESC and batteries were inside the aluminium mast ? This could help also in stability during foiling by having the center of gravity lower and in the center (?)

There is not much room in the skinny masts we use unless you change the mast shape and widen it. Or you could put everything below in the motor pod. Like a modular strap-on system that you can quickly mount on any kite foil board when there is no wind. Or any SUP/surf foil. I would love something like that. You won’t fit a lot of batteries in there but for short rides this may work. @virus has experimented with it, see here: https://youtu.be/FV1Qgv2K9wI. Let’s explore this some more!