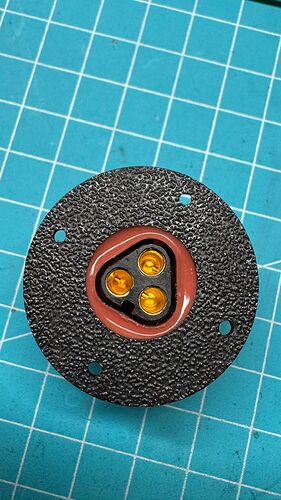

The flat one one is the MR60

Yeah i wasnt 100% sure what he meant about capacitors.

And i agree that using 2 x connectors will add additional resistance. My initial version will probably not have any connectors for the phase wire (just solder both ends ) and will use an off-the-shelf waterproof gland to pass the cable through the (under board) box.

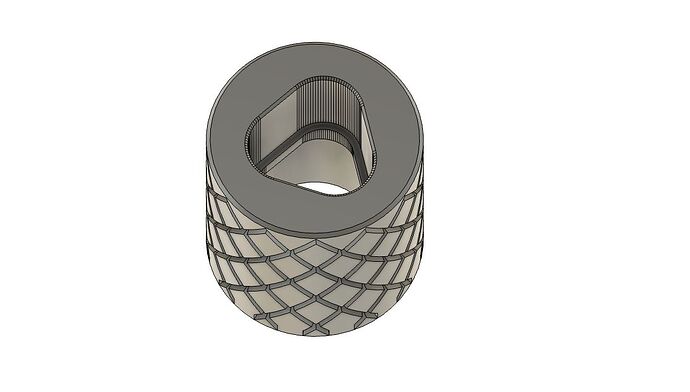

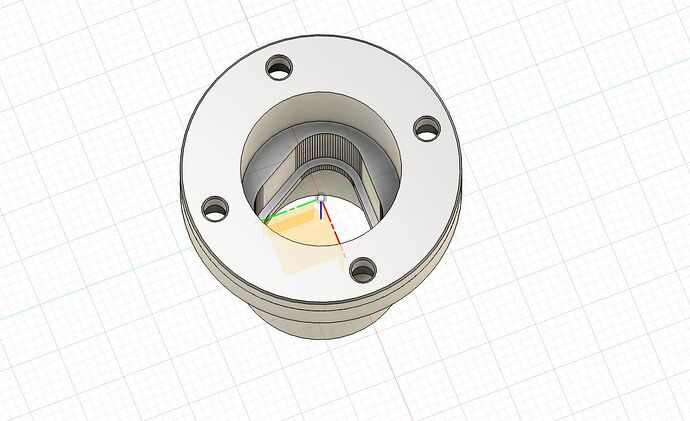

I have further optimized my MTW-60.

This time it is only plugged in without a screw connection.

The female side can be installed in the board or on a box. I have created a ring for the built-in socket to glue to the board, for example.

The socket is then screwed on.

!

may i know what is the red seal glue you use?

These are very nice! Great form factor and design.

@mkefoil

Answering

'Foil Drive Assist, DIY - #1649 by mkefoil

Without any actual usage experience feedback at this moment.

I connected motor cable parts using glue solder heatshrink by soldering first the wires and not using the solder feature of heatshrink. Then put silicone above and regular heatshrink above that.

And this is how I connected MT60 - put epoxy inside the back of the connectors, then I will put silicone with heatshrink above, dialectric gel around the pins.

It was hard to solder 12AWG wires, so should have probably straight use the above @hangloose connector…

The 3 12awg wires from the Flipsky motor put in a heatshrink (it is not pretty).